A small electromagnetic swing energy harvester

An energy harvester and swing-type technology, applied to electrical components, electromechanical devices, etc., can solve problems such as environmental pollution, repeated charging or replacement due to energy depletion, large weight and volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

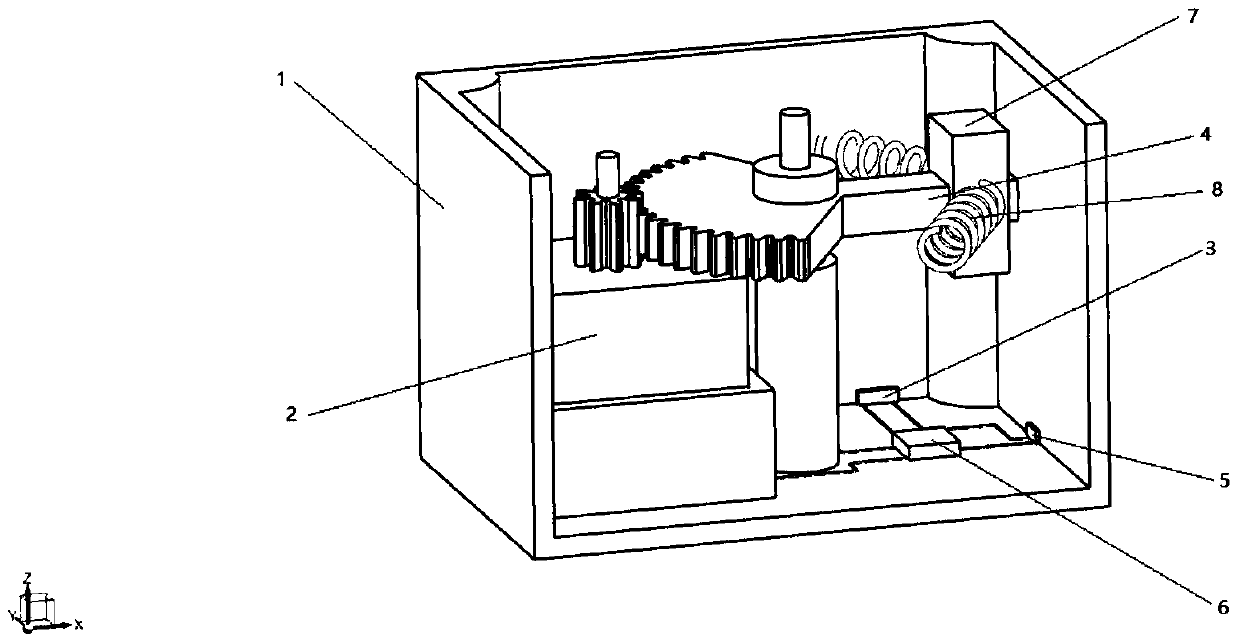

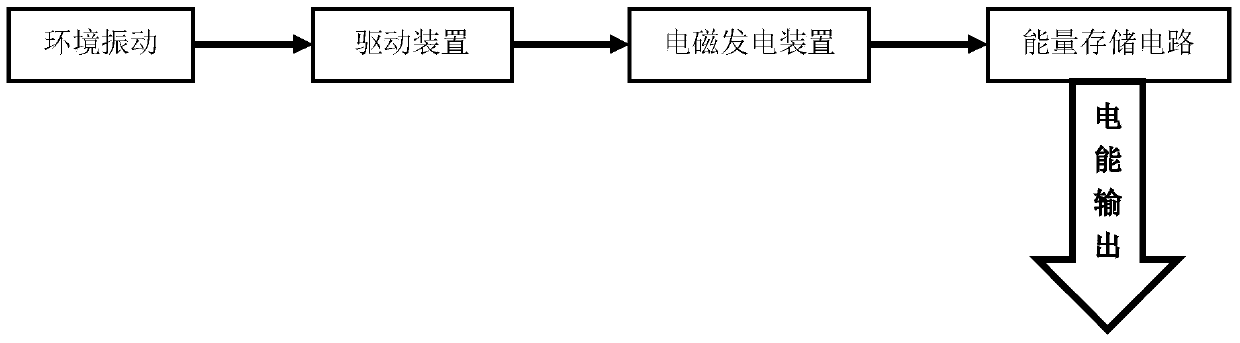

[0022] A small electromagnetic swing type energy harvester, comprising a housing 1, a switch 3, a support spring 8, a driving device 4, a mass block 7, an electromagnetic power generation device 2, an energy storage circuit 6, a mass block 7, and an output interface 5, such as figure 2 , 3 shown.

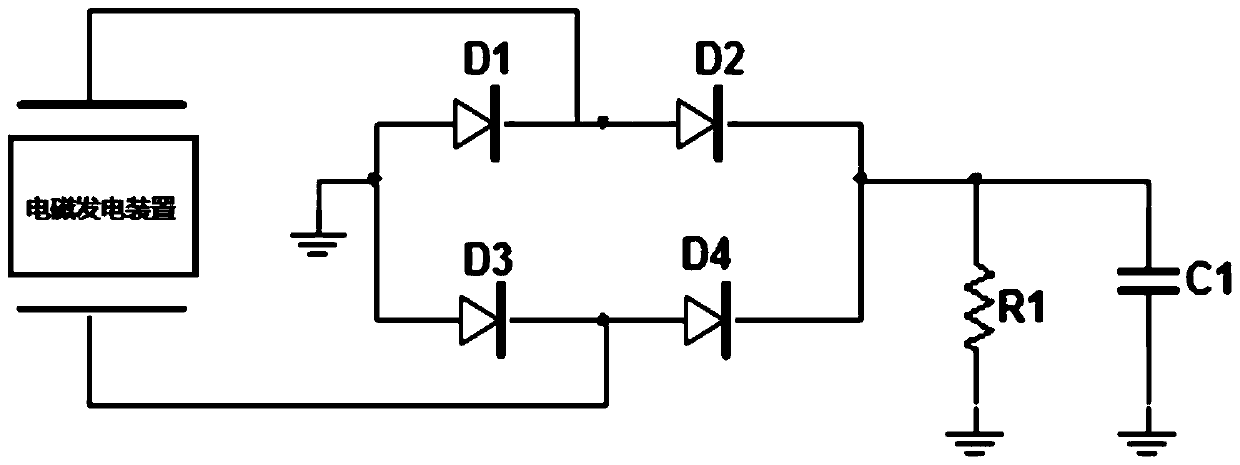

[0023] The casing 1 is provided with a shaft hole for fixing the driving device and a square hole for fixing the electromagnetic driving device. The shaft of the driving device 4 is fixed on the casing 1, and one end is fixed with a mass block 7, which is connected to the casing 1 through a support spring 8, and the other end is a sector gear, and the driving device 4 is integrally fixed on the casing 1 at a certain angle. reciprocating rotation; part of the gears of the driving device 4 and the gears in the electromagnetic power generation device 2 mesh with each other for transmission. The stator of the electromagnetic generator 2 is connected to the energy storage circuit 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com