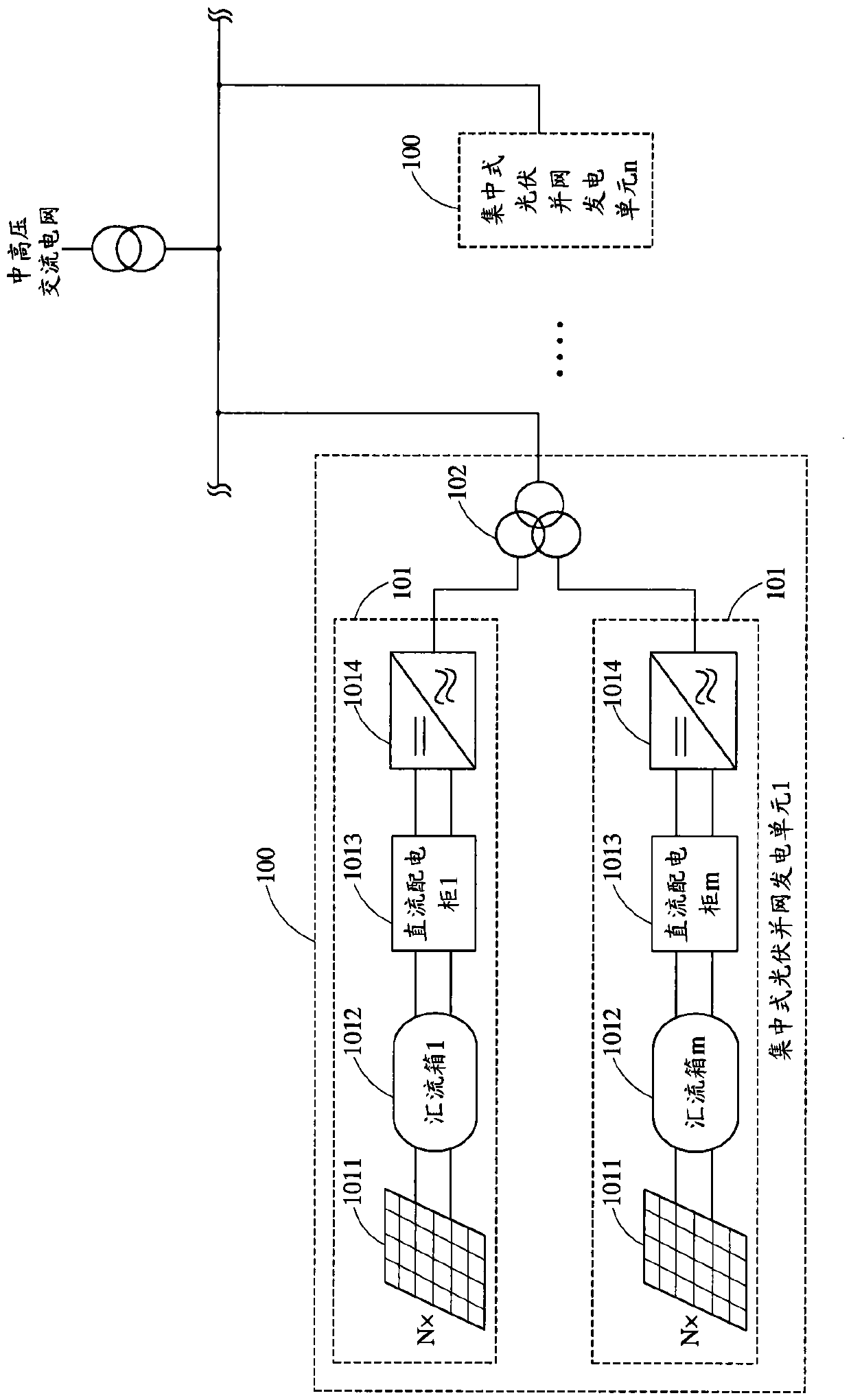

A photovoltaic grid-connected power generation system based on medium and high voltage direct current access

A technology for DC power generation and grid-connected power generation, applied in the field of solar photovoltaic power generation, can solve the problems of weak immunity, long capital operation cycle, high initial investment cost of new energy power generation, and achieve the effect of reducing line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

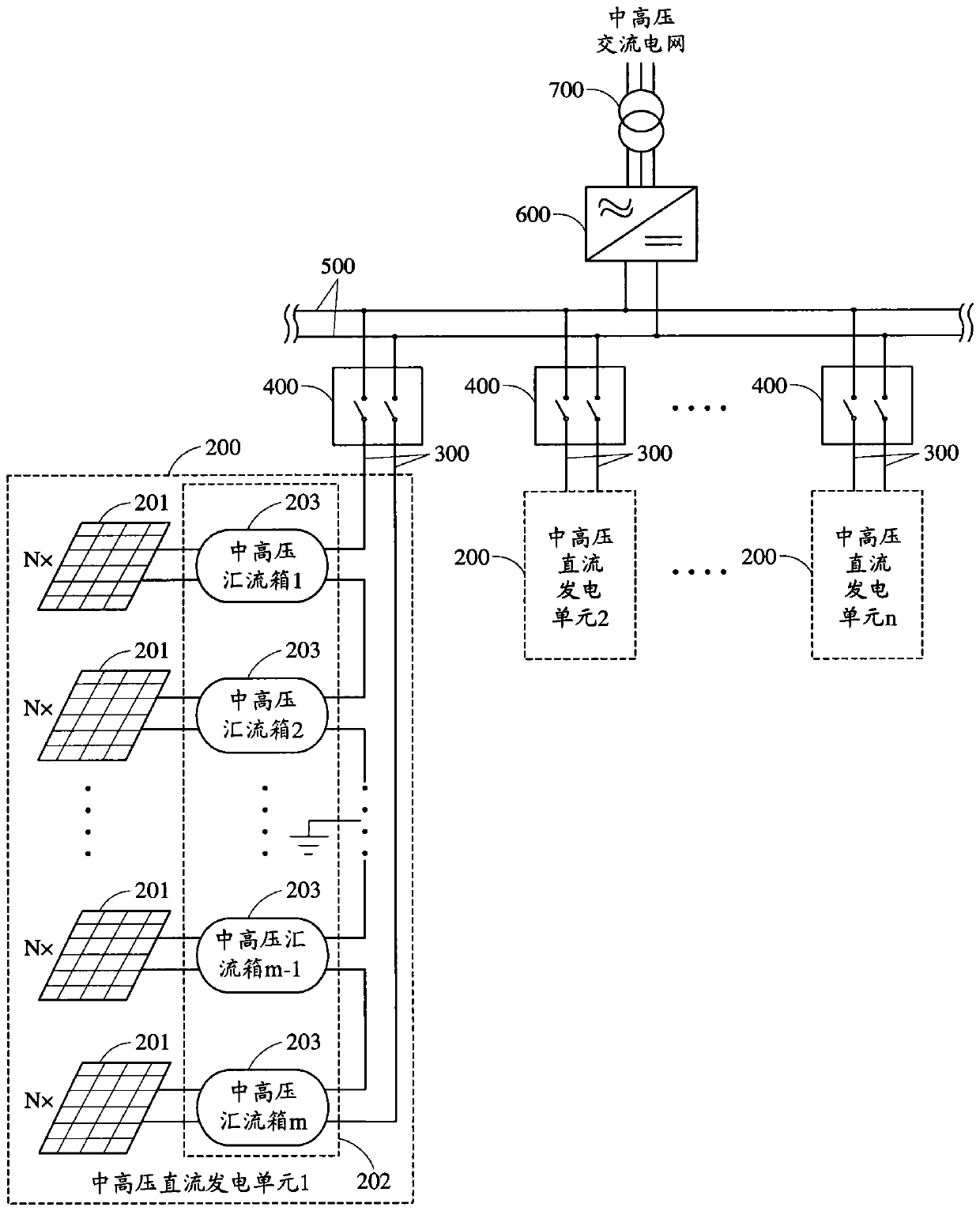

[0039] Such as figure 2 As shown, this embodiment provides a photovoltaic grid-connected power generation system based on medium and high voltage DC access, which includes: n medium and high voltage DC power generation units 200, n isolation switches 400 and 1 medium and high voltage centralized photovoltaic grid-connected inverter Inverter 600, wherein, n is an integer greater than 0, and the number of medium and high voltage DC power generation units 200 is the same as that of isolating switches 400 and corresponds to each other. Each medium and high voltage DC power generation unit 200 is connected in parallel through its corresponding isolating switch 400. By increasing the number of medium and high voltage DC power generation units 200 and their corresponding isolating switches 400, the capacity of the system can be easily increased and expanded; moreover, each medium The high-voltage DC power generation unit 200, each isolating switch 400 and the medium and high-voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com