Preparation method of SnO2/C fiber

A fiber, mixed fiber technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor conductivity, large volume change, poor cycle stability, etc., to achieve high specific capacity, uniform surface distribution, design simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

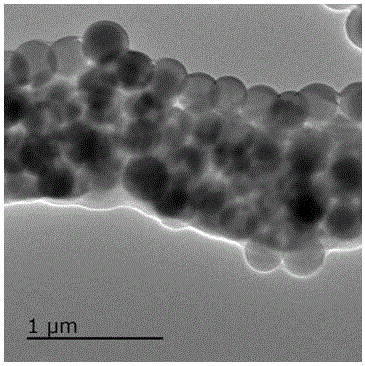

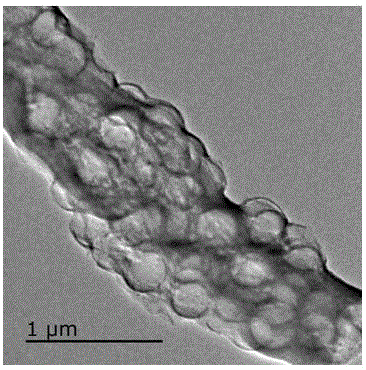

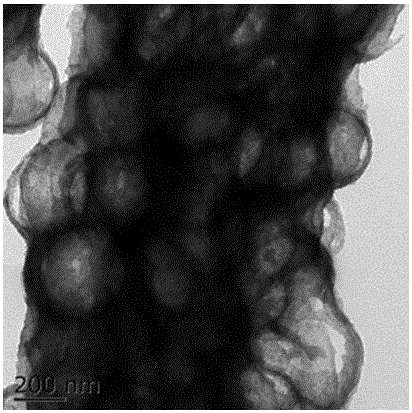

Image

Examples

Embodiment 1

[0028] (1) Preparation of SiO 2 / PAN / PVP mixed fiber:

[0029] Dissolve 0.76g of PVP in 4mL of DMF solution and stir until uniform to obtain a DMF dispersion of PVP.

[0030] 1.52g of SiO 2 Added to 4mL DMF solution, sonicated for 1h to make SiO 2 Evenly dispersed to obtain SiO 2 DMF solution.

[0031] SiO 2 Add the DMF solution of PVP into the DMF dispersion of PVP, stir and mix evenly, then add 0.76g PAN in portions, stir for 4-5h until a transparent colloid is formed, and then the mixed spinning solution is obtained.

[0032] Inject the mixed spinning solution into a 10mL syringe equipped with a needle with an inner diameter of 6mm, place it on an electrospinning machine, set a voltage of 15kV, a distance between the needle and a receiving plate of 15cm, and a spray speed of 0.2mm / min for electrospinning, and obtain SiO 2 / PAN / PVP mixed fiber.

[0033] (2) Preparation of SiO 2 / C fiber:

[0034] Take the SiO prepared above 2 / PAN / PVP mixed fibers were placed in a...

Embodiment 2

[0040] (1) Preparation of SiO 2 / PAN / PVP mixed fiber:

[0041]Dissolve 0.76g of PVP in 4mL of DMF solution and stir until uniform to obtain a DMF dispersion of PVP.

[0042] 1.52g of SiO 2 Added to 4mL DMF solution, sonicated for 1h to make SiO 2 Evenly dispersed to obtain SiO 2 DMF solution.

[0043] SiO 2 Add the DMF solution of PVP into the DMF dispersion of PVP, stir and mix evenly, then add 0.76g PAN in portions, stir for 4-5h until a transparent colloid is formed, and then the mixed spinning solution is obtained.

[0044] Inject the mixed spinning solution into a 10mL syringe equipped with a needle with an inner diameter of 6mm, place it on the electrospinning machine, set the voltage at 15kV, the distance between the needle and the receiving plate is 15cm, and the spray speed is 0.2mm / min for electrospinning, and obtain SiO 2 / PAN / PVP mixed fiber.

[0045] (2) Take the SiO prepared above 2 / PAN / PVP mixed fiber is placed in a vacuum tube furnace, pre-filled with...

Embodiment 3

[0051] (1) Preparation of SiO 2 / PAN / PVP mixed fiber:

[0052] Dissolve 0.76g of PVP in 4mL of DMF solution and stir until uniform to obtain a DMF dispersion of PVP.

[0053] 1.52g of SiO 2 Added to 4mL DMF solution, sonicated for 1h to make SiO 2 Evenly dispersed to obtain SiO 2 DMF solution.

[0054] SiO 2 Add the DMF solution of PVP into the DMF dispersion of PVP, stir and mix evenly, then add 0.76g PAN in portions, stir for 4-5h until a transparent colloid is formed, and then the mixed spinning solution is obtained.

[0055] Inject the mixed spinning solution into a 10mL syringe equipped with a needle with an inner diameter of 6mm, place it on the electrospinning machine, set the voltage at 15kV, the distance between the needle and the receiving plate is 15cm, and the spray speed is 0.2mm / min for electrospinning, and obtain SiO 2 / PAN / PVP mixed fiber.

[0056] (2) Preparation of SiO 2 / C fiber:

[0057] Take the SiO prepared above 2 / PAN / PVP mixed fiber is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com