Cover board assembly for power battery and power battery

A technology of power battery and cover plate, applied in the field of power battery cover plate assembly and power battery, can solve the problems of unstable welding, easy deformation of buffer part, tearing, etc., so as to improve the safety of use, reduce the probability of rupture, and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

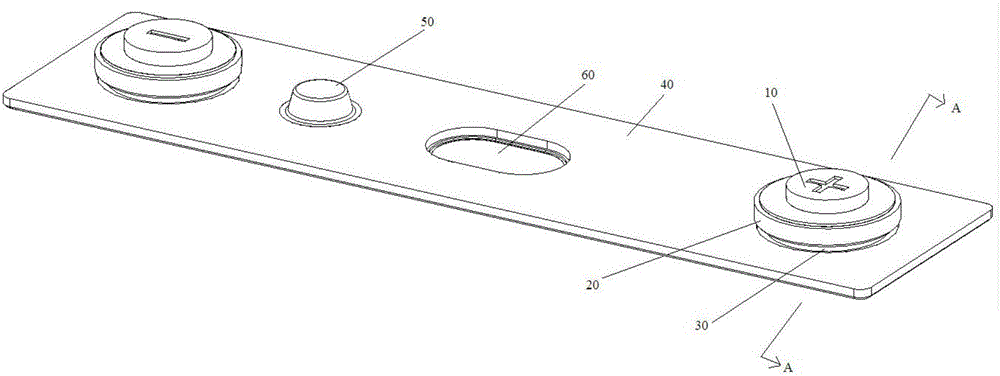

[0051] refer to Figure 1 to Figure 7, the embodiment of the present invention provides a power battery cover plate assembly, including a pole 10, an insulator 20, a composite flange 30 and a cover body 40; the above pole 10 includes a top end and a bottom end, between the top end and the bottom end The pole 10 is provided with a welding portion 11 protruding around the pole 10, the welding portion 11 includes a lower platform 113, a buffer wall 112 and an upper platform 111, the lower platform 113 is connected with the pole 10, and the lower ladder The side of the platform 113 away from the pole 10 is connected to the buffer wall 112, and the buffer wall 112 is also connected to the upper platform 111; The distance on the plane; the insulator 20 is provided with a pole installation hole, the bottom end of the pole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com