Controllable abrasion load test device

A test device and load test technology, which is applied in the direction of testing wear resistance, etc., can solve the problem of small load range and achieve the effects of reducing test cost, improving accuracy and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

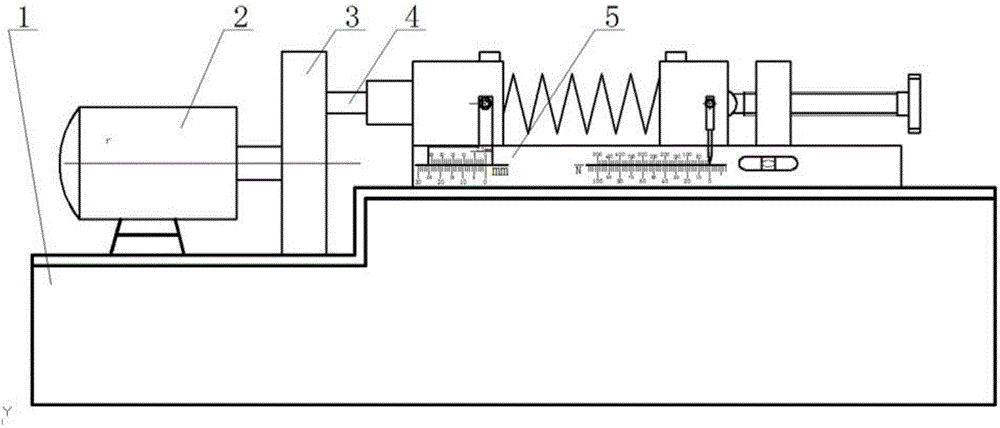

[0031] The invention provides a test device with controllable wear load, such as figure 1 As shown, it is composed of workbench 1, motor 2, grinding disc 3, sample 4 and controllable wear load experimental device 5; grinding disc 3 is connected to motor 2, motor 2 is fixed on the workbench, and one end of sample 4 is placed into a On the controllable wear load test device 5, the other end is in contact with the grinding disc 3, and the controllable wear load test device 5 is fixed on the workbench 1; the controllable load loading range is 0-500N; the wear scale wear range is 0-20mm, and the accuracy can reach 0.01mm.

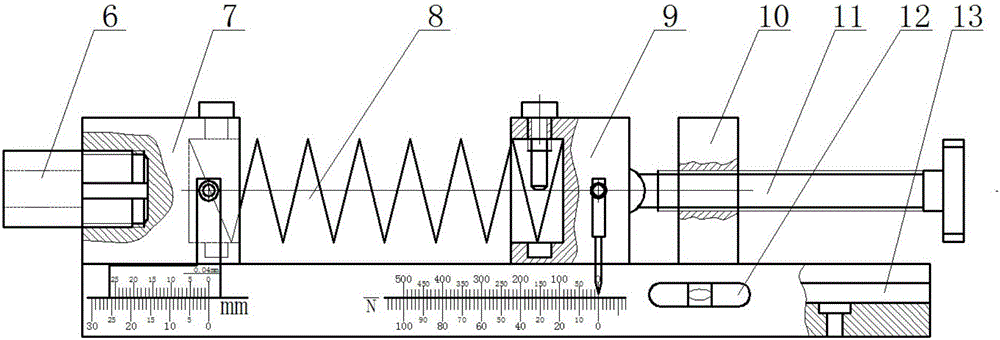

[0032] In this example, if figure 2 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com