Rupture test buffering device of steel wire rope tension testing machine

A tensile testing machine and buffer device technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as affecting work performance, guide screw breakage, screw breakage and scattering, etc. The effect of ensuring normal operation, reducing device vibration and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

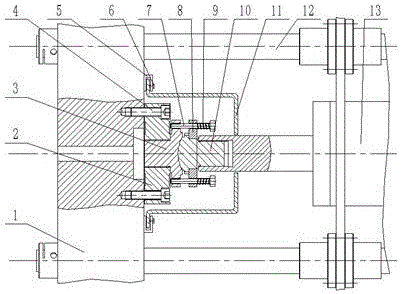

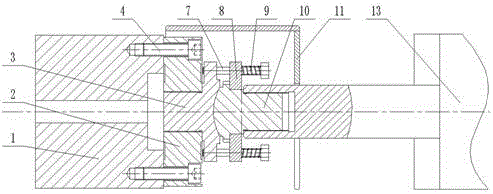

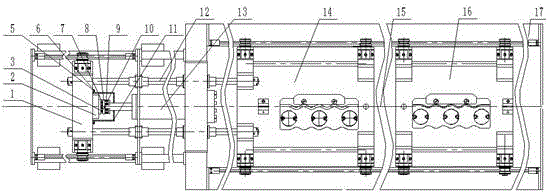

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , figure 2 , image 3 As shown, a breaking test buffer device for a wire rope tensile testing machine, the main structure includes a hydraulic cylinder 13, a force applying ball head 10, a pull plate 8, a force applying seat 3, a sensor 2, a front top beam 1, a spring 9, a guide screw 7, an inner Hex screw 4, protective cover 11, guide positioning plate 5, screw 6, described sensor 2 is fixed on the described front top beam 1 by described hexagon socket screw 4, described force applying ball head 10, force applying seat 3 are respectively connected with the piston rod of the hydraulic cylinder 13 and the sensor 2 through a thread structure, the pull plate 8 is set on the force applying ball head 10, and the six uniformly distributed guide screws 7 pass through the The pull plate 8 connects the force application ball head 10 and the force application seat 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com