Machine tool guide rail installation plane parallelism quick measurement device and method

A technology for installing planes and measuring devices, applied to measuring devices, electrical devices, instruments, etc., can solve the problems of complex operation, high price, and unsuitability for large-scale applications, and achieve the effects of ensuring measurement accuracy, simple device structure, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

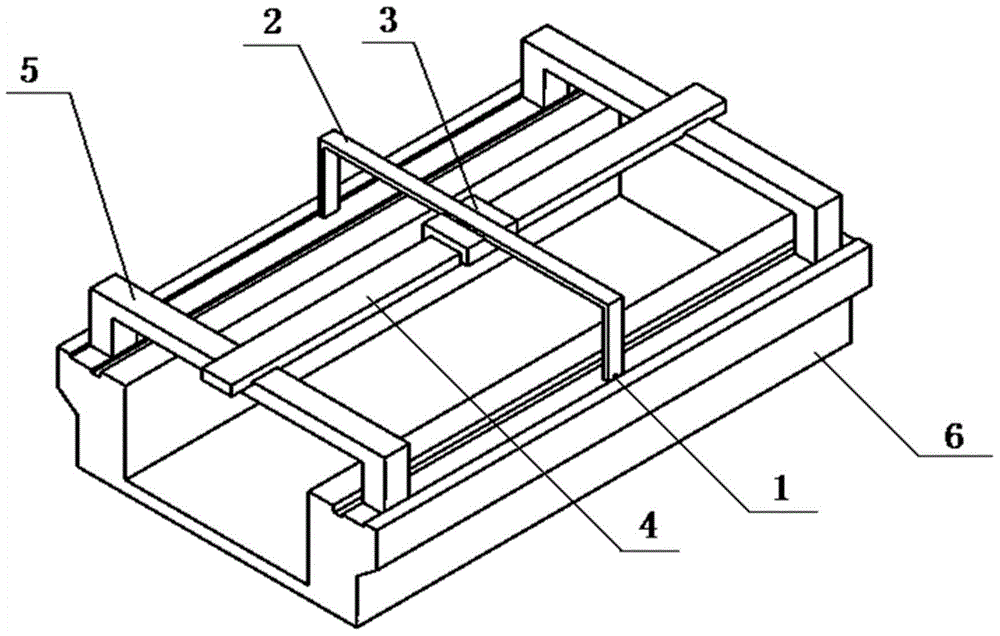

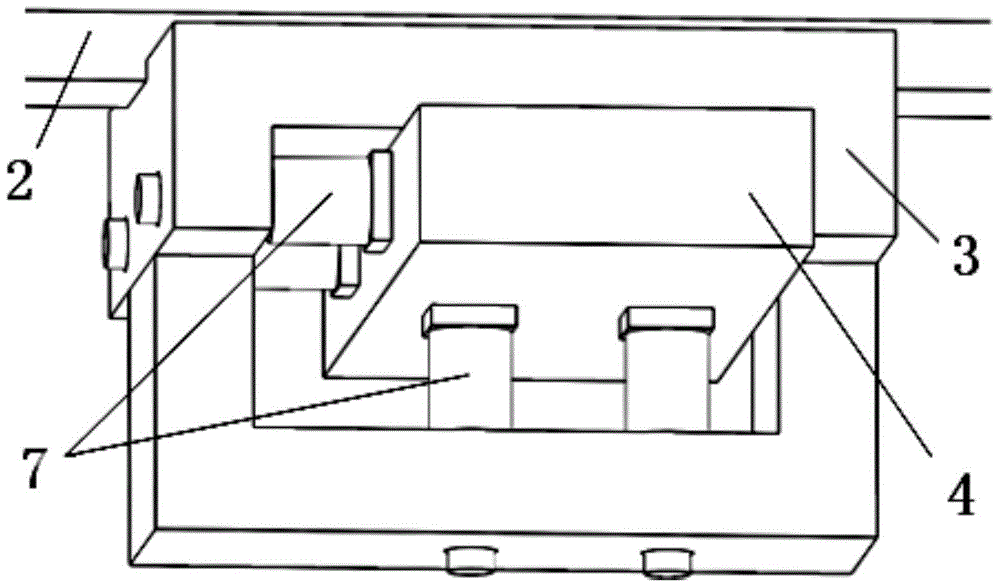

[0035] see Figure 1-4 , the present invention machine tool guide rail mounting plane parallelism fast measuring device comprises four eddy current sensors 1, sensor mounting bracket 2, slide block 3, flat ruler slide rail 4, measuring system bracket 5, tested machine bed 6. Among them, the machine bed 6 to be tested needs to be fixed on the ground with fastening screws and leveled before it is measured; the two measurement system brackets 5 are installed on the guide rails of the machine bed 9 to be tested. The plane is clamped by the wedge block so that it is close to the side and bottom surface of the guide rail installation plane; the marble-made flat ruler slide rail 4 is placed in the limit groove above the measurement system bracket 5 so that it is in line with the measured machine bed The installation planes of the guide rails 6 are basically paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com