Novel one-way valve element structure

A technology of one-way valve and spool, which is applied in the field of one-way valve spool structure and new one-way valve spool structure, which can solve problems such as valve stem fracture, achieve the effect of avoiding welding connection, simple structure and clear working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings:

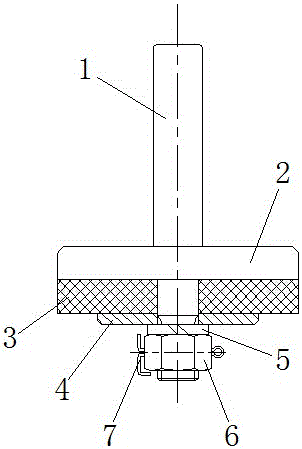

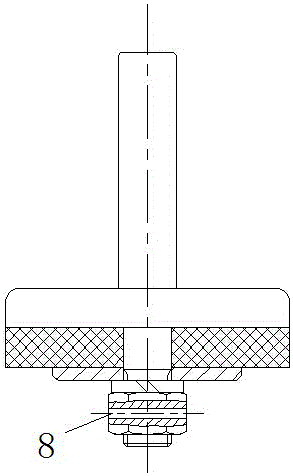

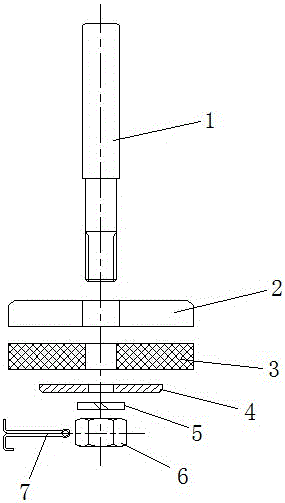

[0017] Such as Figure 1-3 As shown, a new type of check valve core structure, the valve core structure is composed of the valve stem 1, the valve plate 2, the sealing gasket 3, the pressure plate 4 and the nut 6. The valve stem 1 is a step shaft, and the shaft head of the step shaft is processed With external threads, the valve plate 2 is sleeved on the shoulder of the stepped shaft, the gasket 3 is placed under the valve plate 2, the pressure plate 4 is placed under the gasket 3, the nut 6 is tightened under the pressure plate 4, The tightened nut 6 is provided with a pin hole 8 penetrating the valve stem, and a plug pin 7 is provided in the pin hole 8.

[0018] Such as Figure 1-3 As shown, a new type of check valve core structure, the center of the valve plate 2 has a through hole, the through hole of the valve stem and the step shaft of the valve stem form a clearance fit; the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com