Pressure guiding module mounted in flute-shaped pipe

A flute-shaped tube and component technology is applied in the field of pressure-implanting components, which can solve the problems of welding penetration, large changes in the diameter of the flute-shaped tube, and high probability of defective products, and achieves the effect of reducing the defect rate and avoiding welding connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

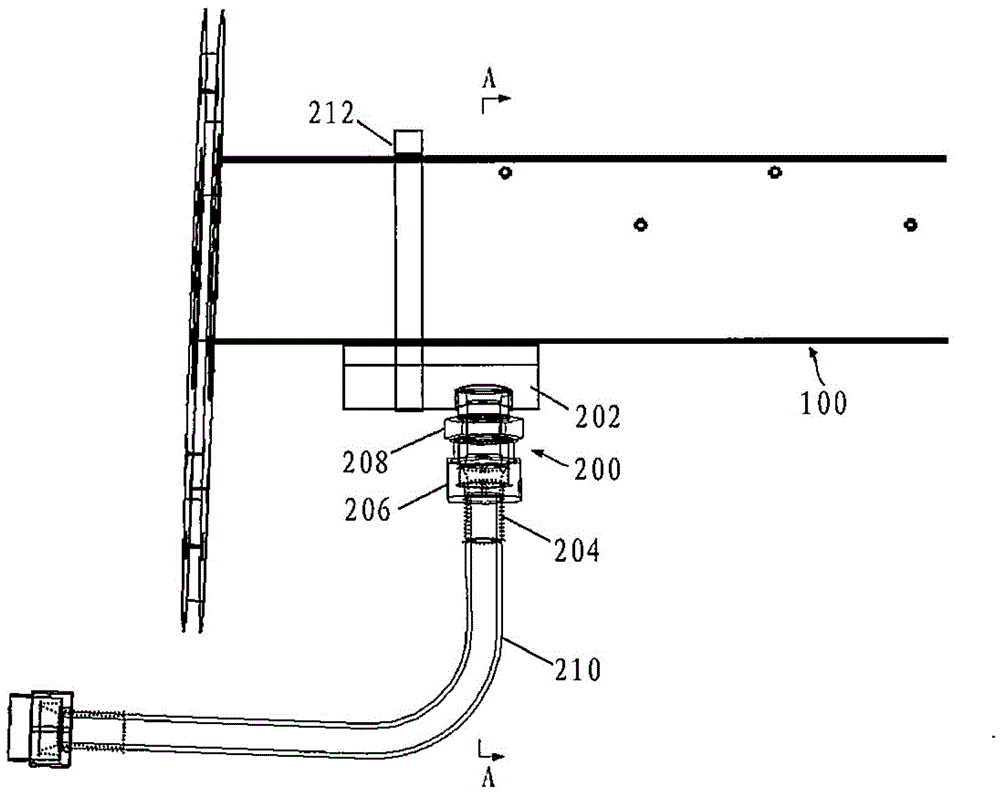

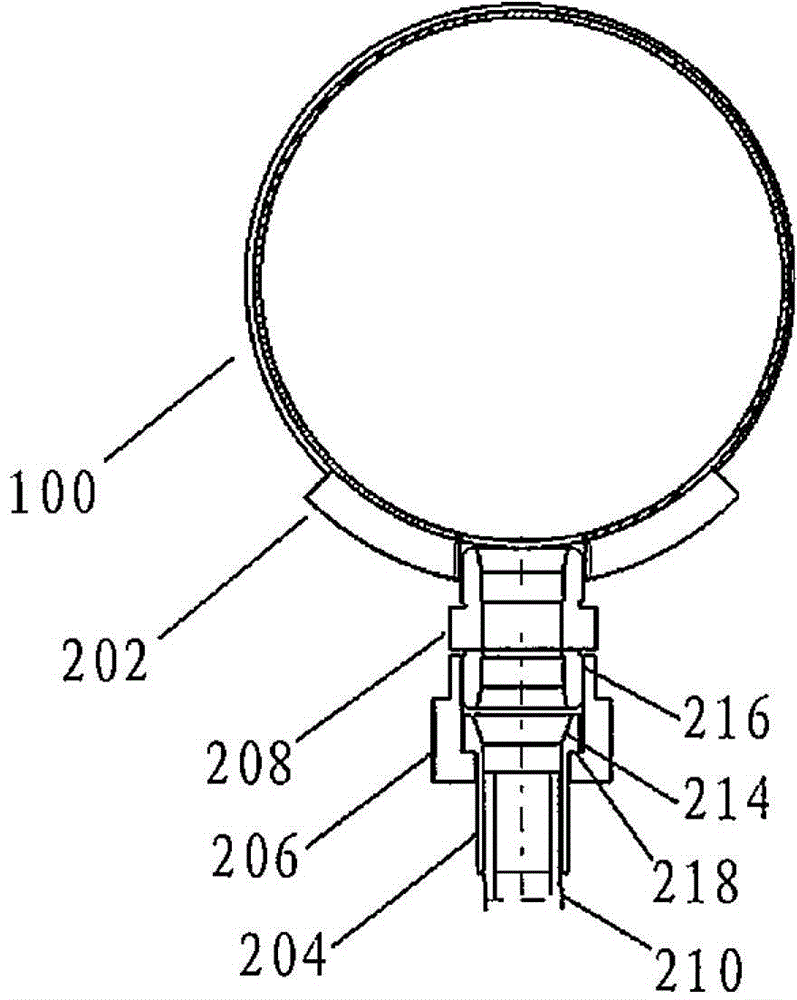

[0019] Such as figure 1 with figure 2 As shown, a pressure introduction assembly 200 installed on a piccolo tube 100, wherein the piccolo tube 100 has a first through hole, the pressure introduction assembly 200 includes a base 202, a tube sleeve 204, an outer casing nut 206, and a straight joint 208 And pressure induction pipe 210.

[0020] Specifically, the base 202 is a thin plate-shaped part made of aluminum material, which has a joint surface adapted to the outer surface of the piccolo 100. Specifically, as shown in the figure, the joint surface is arc-shaped and the curvature of the joint surface is the same as The outer surfaces of piccolo 100 have the same curvature. There is also a second through hole on the base 202, the hole wall of the second through hole is also provided with internal thread, when the base 202 is bound to the flute tube 100 by the high temperature resistant tape 212, the joint surface of the base 202 and The outer surfaces of the piccolo 100 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com