Hole drilling hole position and depth self-adjusting type tunnel blasting hole drilling device

A drilling device and self-adjusting technology, which is applied in the direction of supporting devices, drilling equipment and methods, drilling equipment, etc., can solve the problems of long time consumption, large manpower and material resources, and affecting the tunnel construction period, so as to achieve convenient installation and layout. The effect of low cost, practical installation and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

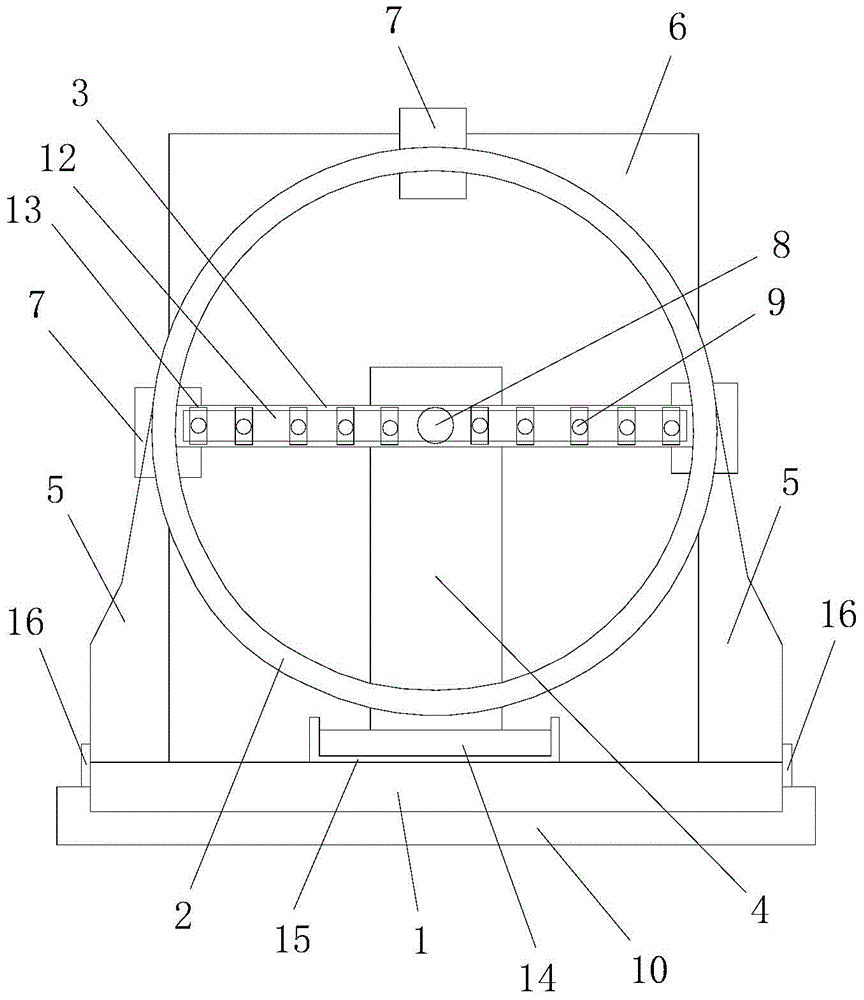

[0036] Such as figure 1 , figure 2 As shown, the present invention comprises a horizontal base plate 10, a horizontal base plate 1 installed on the horizontal base plate 10, a drilling device arranged above the horizontal base plate 1 and capable of moving back and forth on a horizontal plane, and promoting the drilling device to move back and forth and A push mechanism for adjusting the drilling depth of the drilling device accordingly.

[0037] The drilling device includes a circular track 2 positioned above the front side of the horizontal base plate 1, a drilling frame that is installed on the circular track 2 and can rotate 360° along the circular track 2 on a vertical plane 3. Two track support seats 5 respectively supported on the left and right sides of the circular track 2 and a vertical mounting seat 4 located on the rear side of the circular track 2, and the two track support seats 5 are symmetrically arranged left and right; The circular track 2 is arranged vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com