Welding-free double-side-covered flower type door frame

A welding-free, door frame technology, applied in the direction of the base frame, etc., can solve the problems of affecting the appearance and quality of the door, increasing the production cost, and not being able to cover the wall, so as to improve the anti-rust and anti-corrosion functions, and reduce the energy consumption cost of production Low, good-looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Now in conjunction with accompanying drawing, the present invention is described in detail:

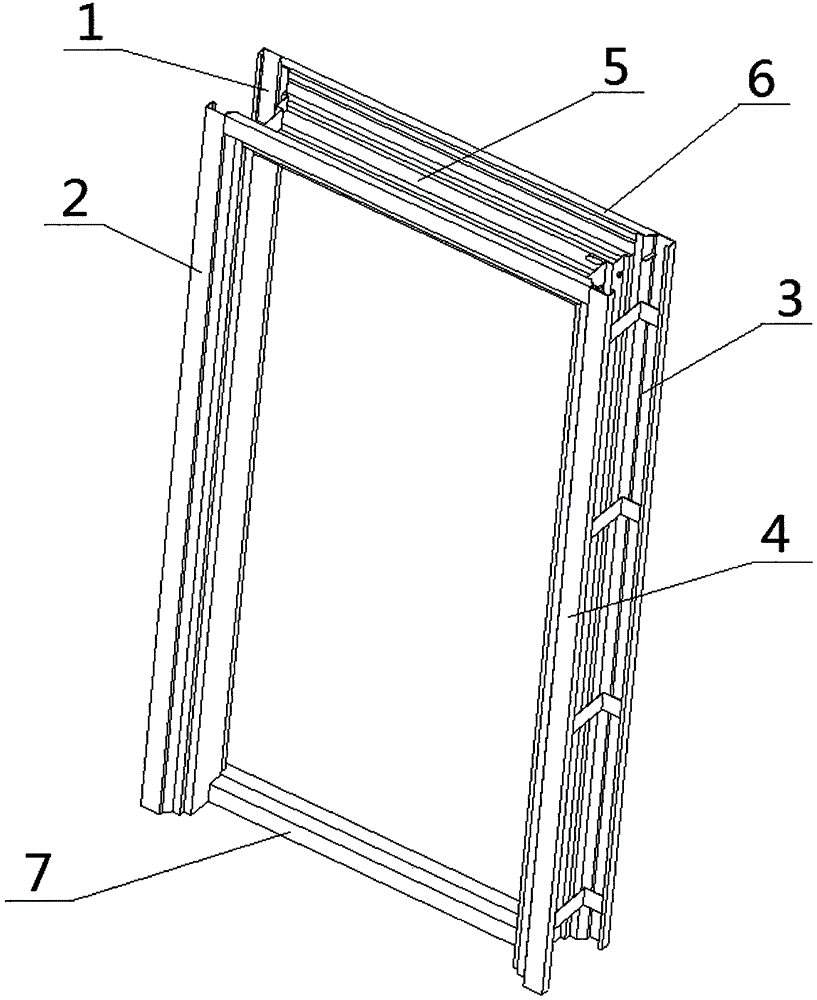

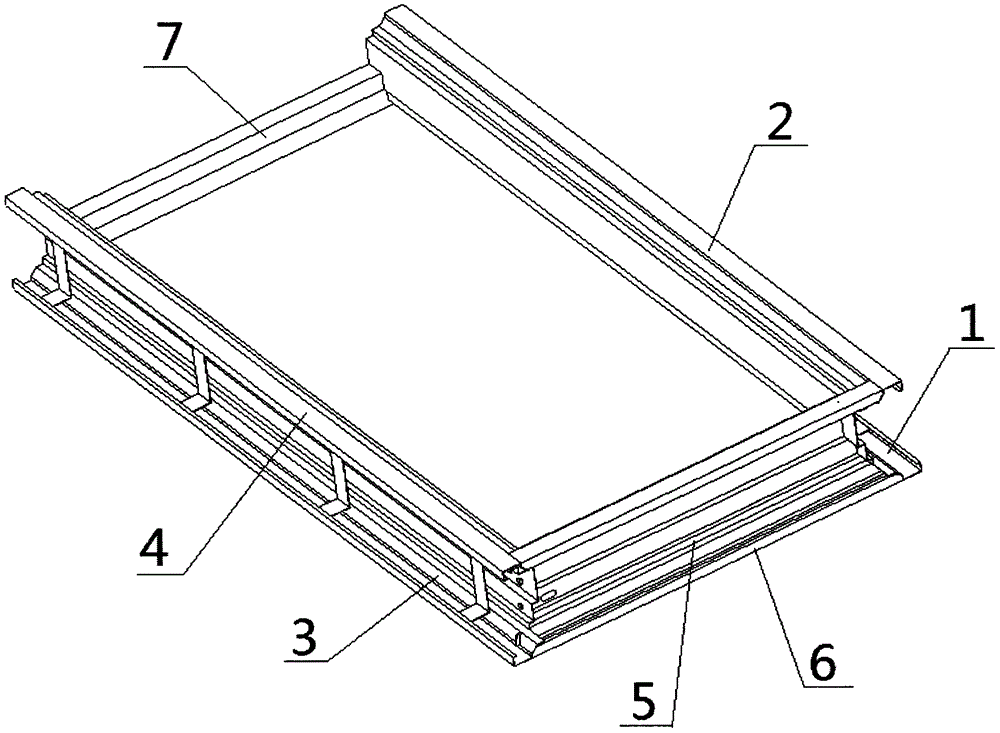

[0048] The present invention is made up of left frame (1), left small pattern frame (2), right frame (3), right small pattern frame (4), upper frame (5), upper frame small pattern frame (6), lower frame ( 7) Composition.

[0049] figure 1 and figure 2 Shown is the structural representation of the present invention.

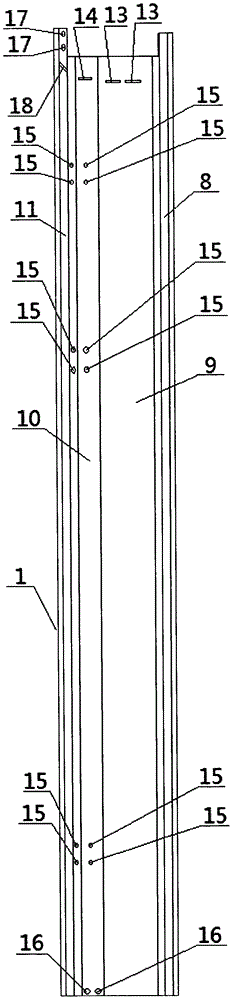

[0050] image 3 , Figure 4 , Figure 5 Shown is a schematic structural view of the left frame (1) in the present invention. The left frame (1) is composed of the door frame splicing surface (8), the door frame wrapping wall (9), the door frame mating surface (10), and the door frame pattern surface (11), and a splicing groove is arranged on the door frame splicing surface (8) (12), at the top of the door frame wall (9) are provided with two snap holes (13), at the top of the door frame mating surface (10) is provided with a snap hole one (14), on the door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com