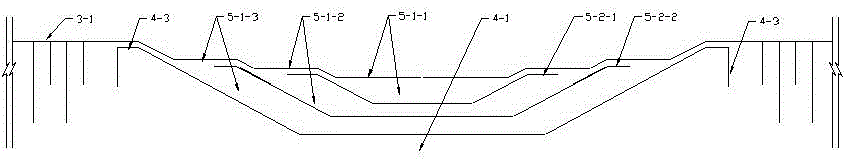

Multi-stage self-collapsing closed headwork

A technology of self-collapsing closed canal head engineering, which is applied in the field of multi-level self-collapsing closed canal head engineering, can solve problems such as unsolvable worldwide problems, dam break and surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Reconstruction of an open head of a rockfill dam with a flood discharge beach. It includes: flood discharge beach 2-2, soil embankment 3, geosynthetic material face protection soil flood diversion dam 4, geosynthetic material protection multi-stage self-collapsing soil embankment 5, water intake 6, barrage gate 7, rockfill dam 8, soil quality Barrage 9, flood diversion farmland 10, gully 11, rope system non-woven grid belt 12, rope system non-woven fabric lock beach wear belt 13, main canal 14. The bottom of the multi-level self-bursting earth dike 5 protected by geosynthetics is connected to the earth flood dike 4-I with geosynthetics surface protection to form a new type of flood diversion structure to divert the flood to the farmland 10, which is arranged on the embankment 3 and discharges to the farmland in stages and controllably. Exceeding standard floods to avoid catastrophic embankment breaks and surges. The bottom of the multi-stage self-burst emban...

Embodiment 2

[0040] Example 2: In Example 1, there is no rockfill auxiliary dam, and the multi-stage self-collapsing embankment 5-III protected by geosynthetics is removed, which is the same as in Example 1.

Embodiment 3

[0041] Embodiment 3: In embodiment 2, there is no flood discharge beach, remove the geosynthetic material protection soil flood diversion dam 4-II, the geosynthetic material protection multi-stage self-collapsing soil embankment 5-II, the rope non-woven grid belt 12, the rope non-woven Spinning lock beach wears belt 13, and other is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com