Formaldehyde-free elastic silicone resin dispersion

A technology of silicone resin and dispersion, applied in the field of dispersion, which can solve the problems of rough hand feeling and restriction of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

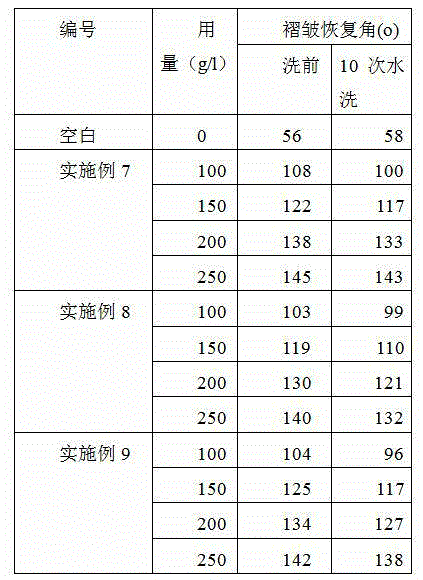

Examples

Embodiment 1

[0042] Example 1: Synthesis of polysiloxane C-1 containing amino groups

[0043] 100.0g octamethylcyclotetrasiloxane, 6.0g 3-(2-aminoethyl)-aminopropylmethyldimethoxysilane, 1.0g hexamethyldisiloxane and 100ppm KOH at 130°C React at low temperature for 8 hours, cool down to room temperature, add 100 ppm phosphoric acid and stir for 30 minutes, then filter and discharge.

Embodiment 2

[0044] Embodiment 2: the synthesis of polysiloxane C-2 containing epoxy group

[0045] 150.0g of octamethylcyclotetrasiloxane, 5.0g of 3-glycidyloxypropylmethyltriethoxysilane, 1.2g of hexamethyldisiloxane and 70ppm of KOH were reacted at 130 degrees Celsius for 8 hours , cooled to room temperature, filtered and discharged.

Embodiment 3

[0046] Example 3: Synthesis of polysiloxane C-3 containing amino groups

[0047] 140.0g of octamethylcyclotetrasiloxane, 3-aminopropylmethyldiethoxysilane, 1.2g of hexamethyldisiloxane and 70ppm of tetramethylammonium hydroxide, reacted at 80 degrees Celsius for 8 hours , after heating up to 160 degrees Celsius and stirring for 30 minutes, the material was filtered and discharged.

[0048] Synthesis example of elastic silicone resin A:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com