Edge sealing method and device for thermoplastic cellular board

An edge banding device and honeycomb panel technology, which can be applied to other household appliances, household appliances, household components, etc., can solve the problems affecting the quality of honeycomb panels, low edge strength, and low production efficiency, so as to achieve good edge banding effect and improve Work efficiency, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

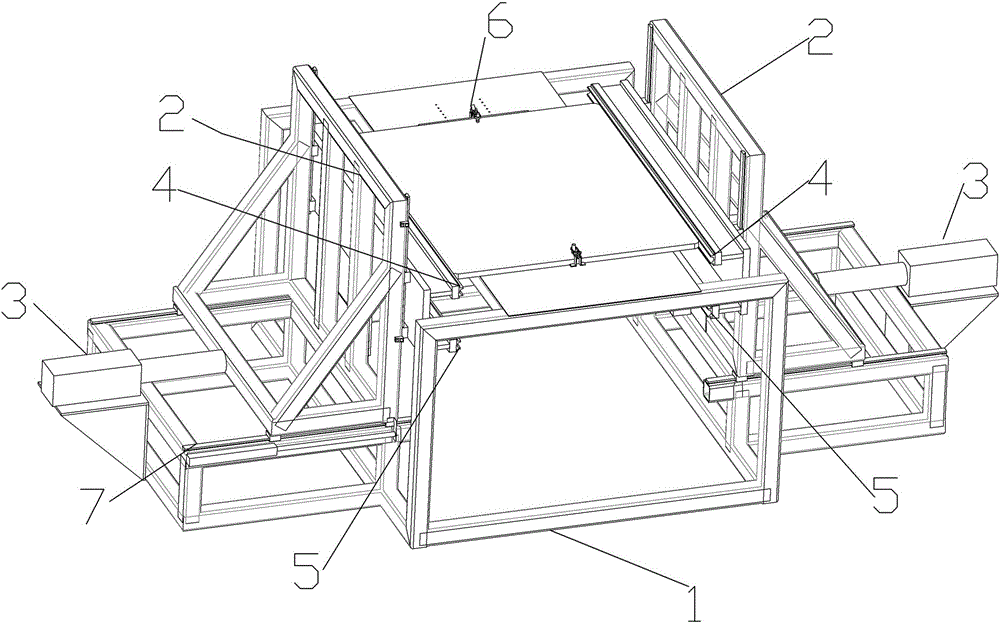

[0029] like figure 1 As shown, a kind of edge banding device of thermoplastic honeycomb panel, comprises workbench 1, is respectively provided with mold support 2 at the two ends of described workbench, is provided with hot mold 4 and cold mold 5 on mold support 2, in mold A linear drive mechanism 3 for driving the mold support 2 to move is connected to the support 2 .

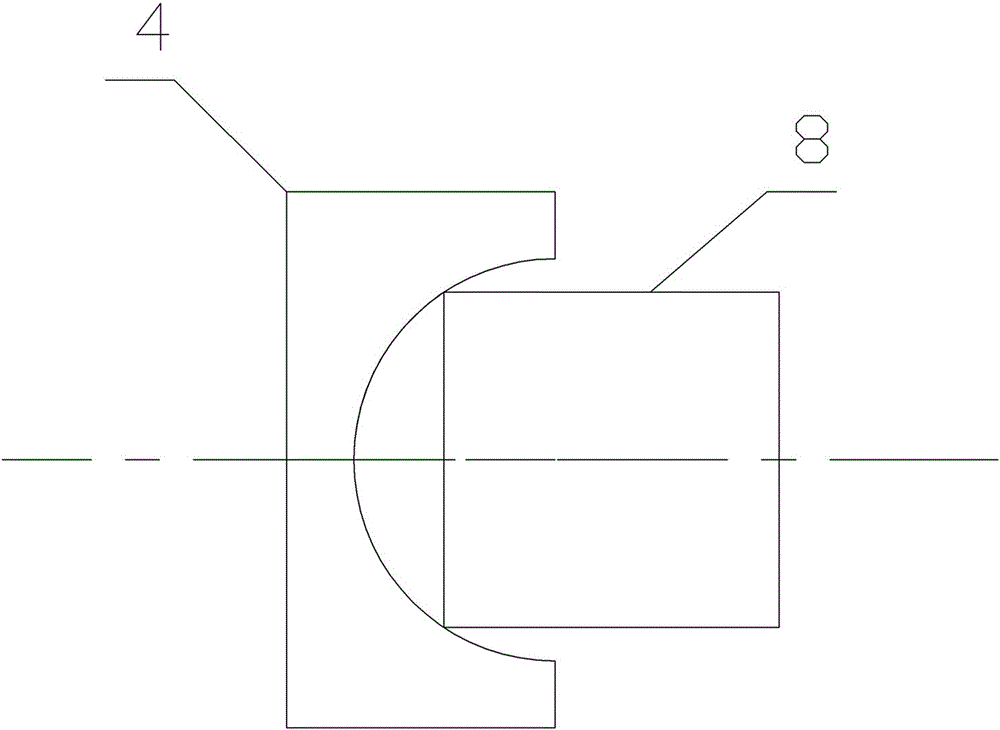

[0030] The hot mold 4 and the cold mold 5 are arranged up and down, the mold support 2 is provided with a bottom plate that can move up and down, the hot mold 4 and the cold mold 5 are fixedly connected to the bottom plate by screws, and the hot mold 4 and the cold mold The mold 5 has arc grooves adapted to the thickness of the thermoplas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com