Plastic shoe tree crusher, shoe tree crushing production line and crushing method

A crusher and production line technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of large labor, high crushing cost, low crushing output, etc. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

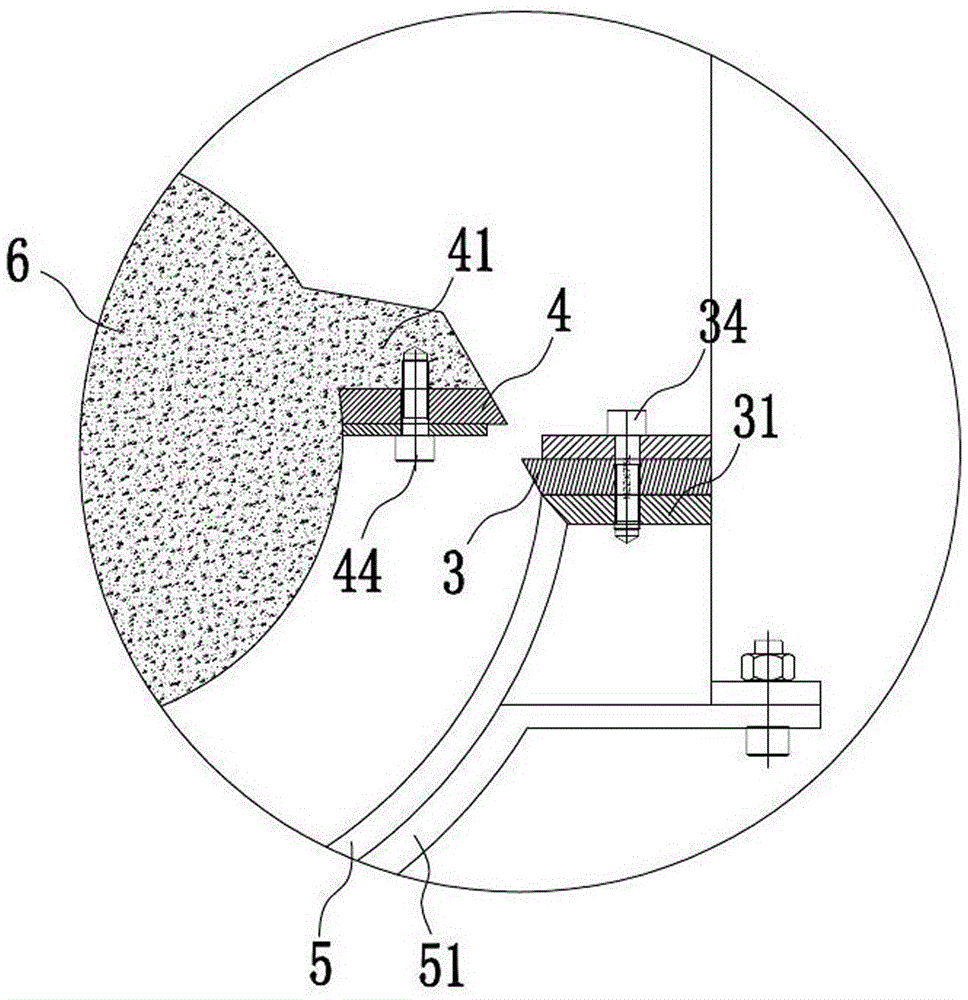

[0047] Such as figure 1 Shown and combined with reference Figure 2 ~ Figure 7 , The present invention is a plastic shoe last crusher 100, including a frame 1, a crushing cavity 2, a fixed knife 3, a movable knife 4, a discharge screen 5, a movable knife roller 6 and a motor 7; the crushing cavity The body 2 is installed on the frame 1, the movable knife roller 6 is installed in the crushing cavity 2, and the movable knife roller 6 is radially provided with a plurality of rows of movable knife grooves, and each row of movable knife grooves is provided with a number of phase shifts. Distributed movable knife seat 41, the movable knife 4 is fixedly installed in the movable knife seat 41, and the blade 43 of the movable knife is higher than the outer surface of the movable knife roller 6; the front and rear ends of the crushing cavity 2 are respectively provided A fixed knife seat, the fixed knife 3 is fixedly installed in the fixed knife seat 31, and the blade 33 of the fixed knif...

Embodiment 2

[0052] Such as Figure 8 As shown, the shoe last crushing production line of the plastic shoe last crusher is characterized in that it includes:

[0053] The shoe last feeding machine 200 is used to feed the plastic shoe last into the crushing cavity 2 of the plastic shoe last crusher 100;

[0054] The plastic shoe last crusher 100 is used for plastic shoe last crushing, and the crushed shoe last scraps are output to the first separation tank 300;

[0055] The first separation tank 300, combined with reference Picture 9 , There is water 302 inside. After the broken shoe last pieces enter the first separation tank 300, the shoe last pieces 303 whose specific gravity is less than water float on the water, and the metal material 304 whose specific gravity is greater than water sinks to the bottom of the pool;

[0056] The first hopper-type loader 400 is used to feed the shoe last scraps floating on the water in the first separation tank 300 into the crushing cavity of the shoe last scrap...

Embodiment 3

[0067] The crushing method of the above shoe last crushing production line includes the following steps:

[0068] a. The shoe last feeding machine sends the plastic shoe last into the crushing cavity of the plastic shoe last crusher;

[0069] b. Adjust the gap distance between the movable knife and the fixed knife of the plastic shoe last crusher, so that the movable knife and the fixed knife can just crush the plastic shoe last. Driven by the motor, the movable knife roller rotates and the movable knife It has a tendency to move relative to the fixed knife, and the gap formed between the movable knife blade and the fixed knife blade causes the shoe last to be broken, and the broken shoe last is output to the first separation tank after passing through the discharge screen;

[0070] c. In the first separation tank, shoe last scraps with a specific gravity less than water float on the water surface, metal materials with a specific gravity greater than water sink to the bottom of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com