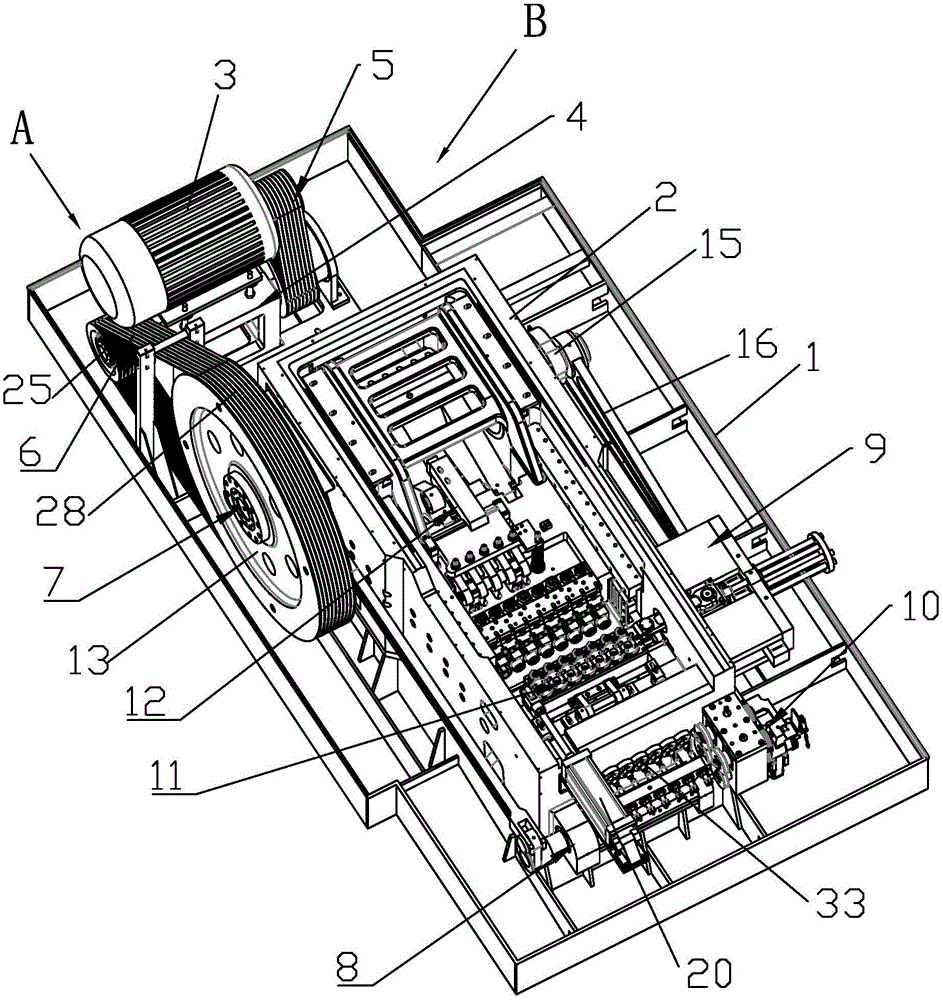

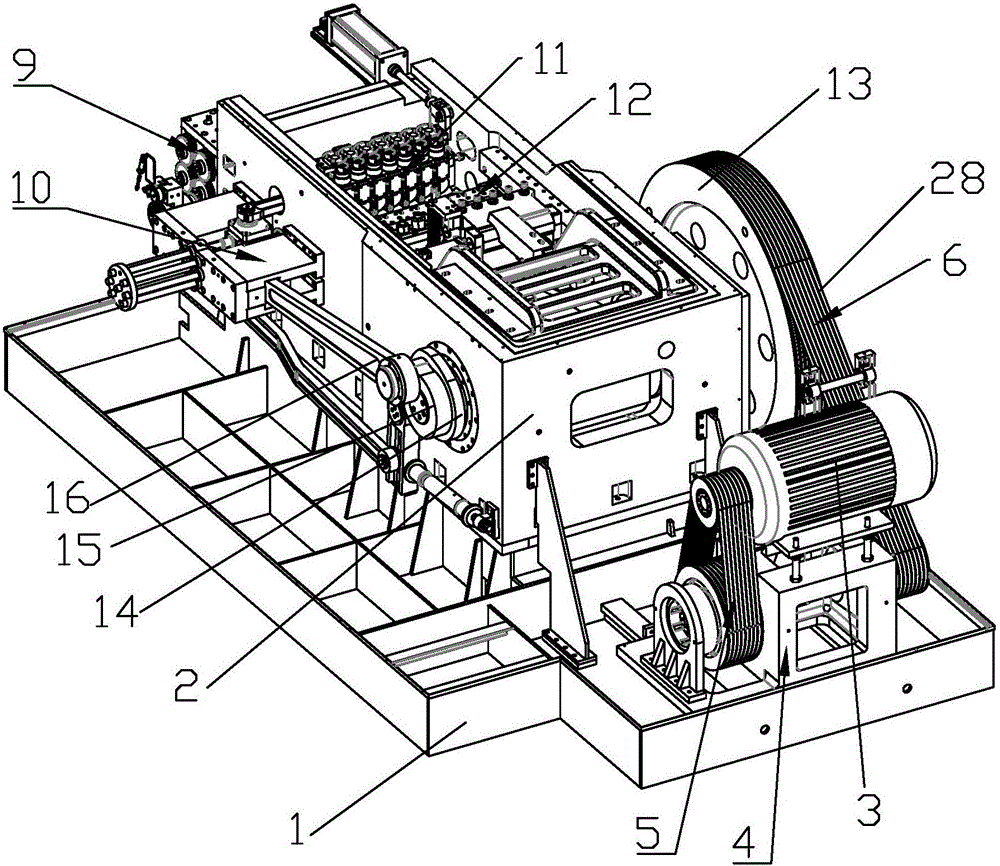

General assembly mechanism of eight-station cold heading machine

A cold heading machine and eight-station technology, which is applied to the driving device, manufacturing tool, operating device, etc. of the forging press, can solve the problems of inconvenient debugging, long processing cycle, and high processing technology requirements, and achieve the effect of speed change and accurate speed change Reliable, effect of improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Such as Figure 1 to Figure 16 As shown, the general assembly mechanism of the eight-station cold heading machine includes a frame 1 and a frame 2. The frame 2 is fixedly installed in the middle of the frame 1. The frame 1 is provided with a main motor 3 and a reduction box device 4. The main motor 3 is connected with a reduction box device 4, and the reduction box device 4 includes a reduction box 26, a first belt deceleration assembly 5 and a second belt deceleration assembly 6, between the first belt deceleration assembly 5 and the second belt deceleration assembly 6 The reduction shaft 25, the reduction shaft 25 crosses the reduction box 26, the main motor 3 is fixedly installed on the reduction box 26, one end of the reduction shaft 25 is connected to the first belt reduction assembly 5, and the first belt reduction assembly 5 is connected to the main motor 3, the reduction shaft The other end of 25 is connected with the second belt deceleration assembly 6, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com