Water-spinning painting room

A spray booth, water cyclone technology, applied in the spray booth, injection device, coating, etc., to achieve the effect of protecting the environment, reducing waste, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

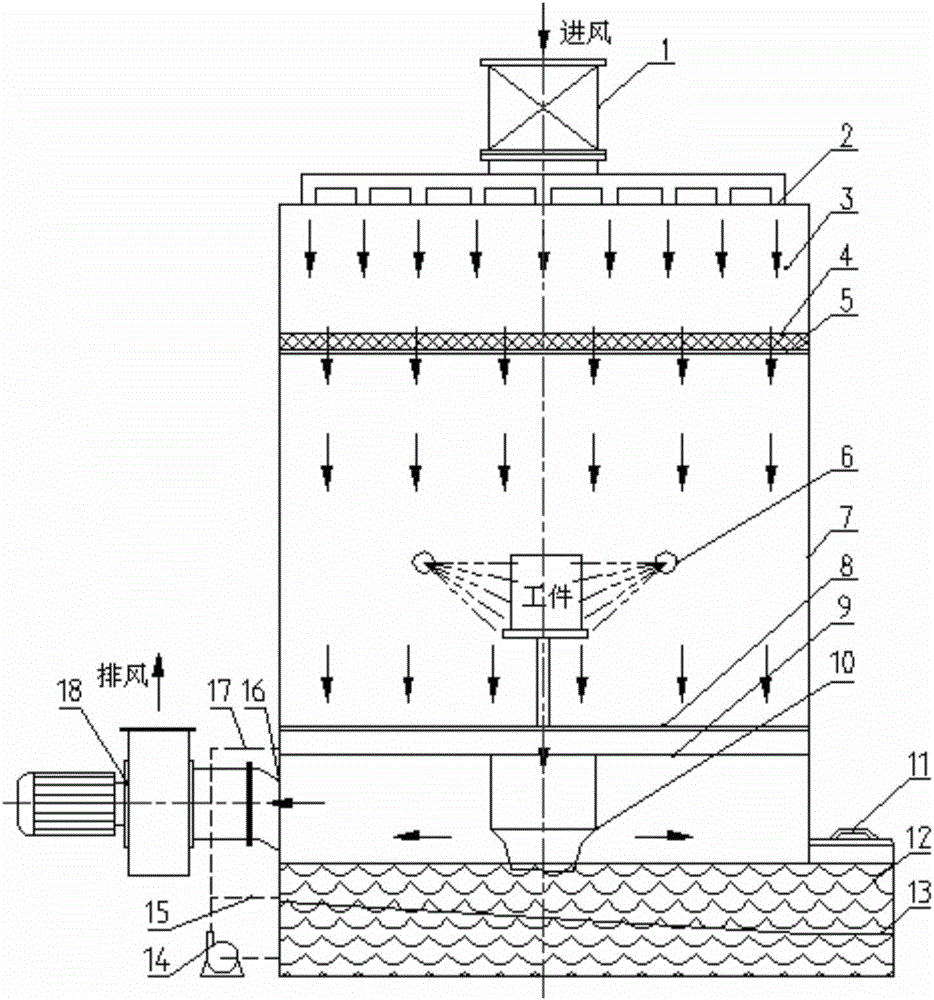

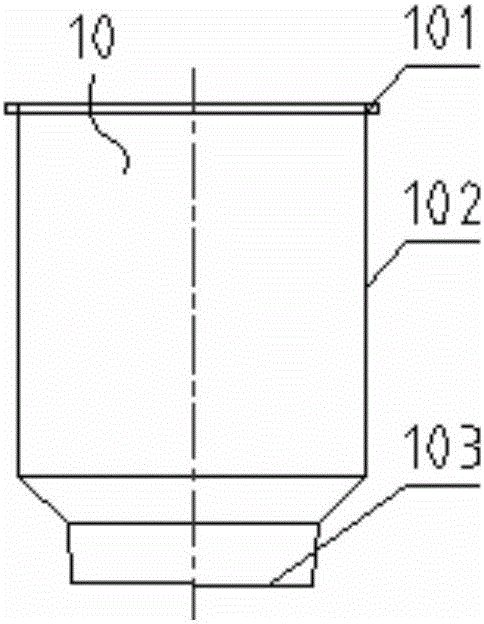

[0042] see figure 1 , the water cyclone spray booth in the figure is divided into three parts, the upper part is the static pressure box 3, the middle is the spray room body 7, and the bottom is the circulating water tank 12, mainly including the air supply system, the exhaust system and the water cyclone treatment system, etc. . Among them, the static pressure box 3 supplies air from the top to the bottom of the spray booth body through the air supply system; the water cyclone treatment system is set below the ground grid plate 8 at the bottom of the spray booth body 7, and the paint mist generated in the process of spray painting is processed. The water is washed and collected, and the water cyclone treatment system is connected with the exhaust system, and the air sent in by the air supply system is discharged outside.

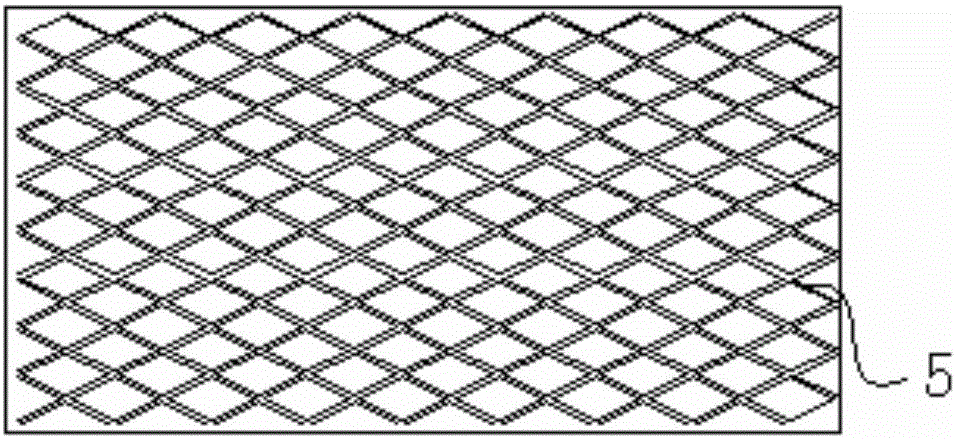

[0043] Specifically, the air supply system includes a fan 1, an air supply port 2, a plenum box 3, a filter cotton 4, an equalizer plate 5, etc., and seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com