Lead-zinc oxide ore flotation inhibitor and application thereof

A lead-zinc oxide and inhibitor technology is applied in the flotation inhibitor of low-grade lead-zinc oxide minerals, and the flotation inhibitor of lead-zinc oxide minerals can solve the problems of poor separation selectivity and achieve high enrichment ratio, process Stable and reliable operation, the effect of improving grade and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The lead-zinc oxide flotation inhibitor used in the present embodiment consists of the following components in parts by mass:

[0038] 50 parts of calcium lignosulfonate,

[0039] 30 parts of sodium pyrophosphate,

[0040] 20 parts of soluble starch.

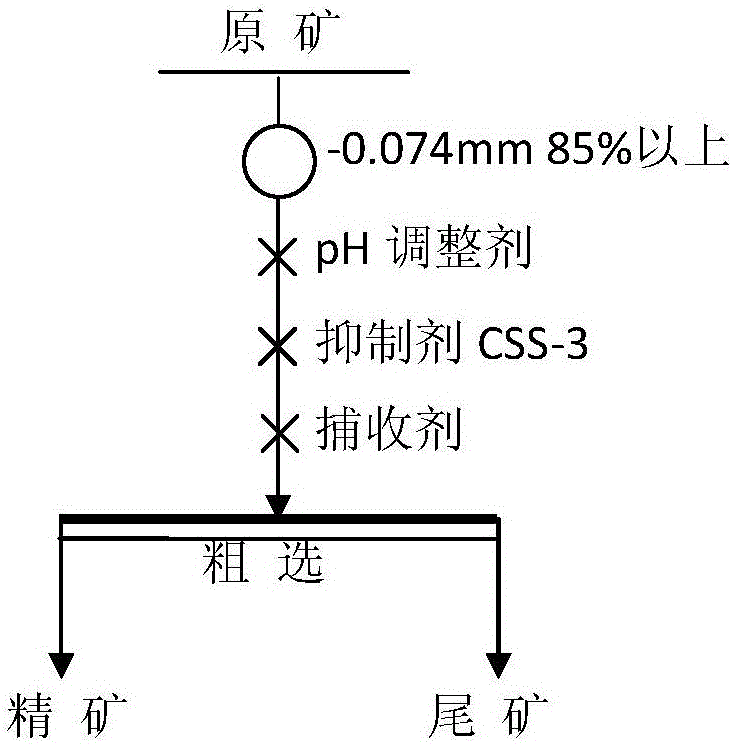

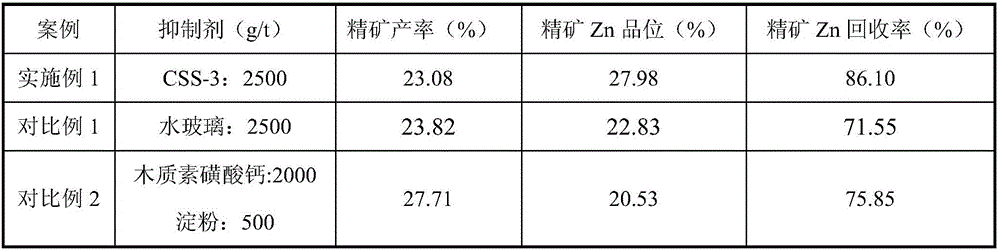

[0041] In this embodiment, a certain low-grade lead-zinc oxide ore sample is used, and the sample contains Pb1.54%, Zn7.50%, SiO 2 20.03%, CaO29.75%, TFe6.05%. For the test procedure of the pharmaceutical system, see figure 1 , under the premise that other pharmaceutical systems remain unchanged, see Table 1 for the test results of comparing water glass as an inhibitor and CSS-3 as an inhibitor.

[0042] In this embodiment, the collector is a mixed collector of xanthate, fatty acid and ether amine. Add collector at the rate of 800g collector per ton of raw ore.

[0043] The specific operation is as follows:

[0044] Grinding the raw ore until the particle size is less than or equal to 0.074mm accounts for more than...

Embodiment 2

[0052] The lead-zinc oxide flotation inhibitor used in the present embodiment consists of the following components in parts by mass:

[0053] 50 parts of calcium lignosulfonate,

[0054] 30 parts of sodium pyrophosphate,

[0055] 20 parts of soluble starch.

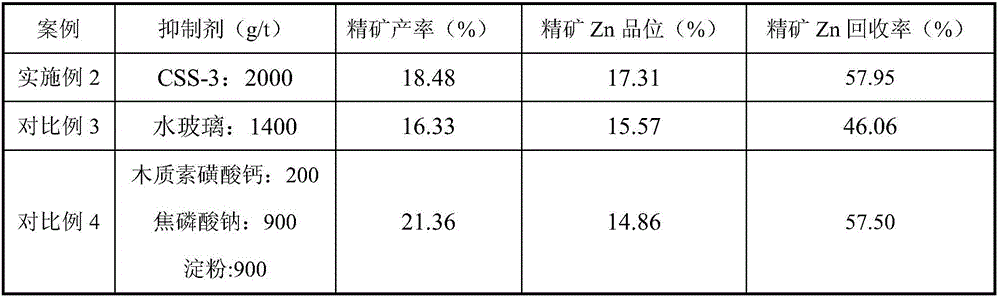

[0056] In this example, a lead-zinc oxide ore sample in Southwest China is used. The raw ore grade is Zn5.52%. figure 1 , in the case of no desliming, and under the premise of other chemical systems unchanged, the test results of comparing water glass as inhibitor and CSS-3 as inhibitor are shown in Table 2.

[0057] In this embodiment, the collector is a mixed collector of xanthate, fatty acid and ether amine. The collector is added at the rate of 750g collector per ton of raw ore.

[0058] The specific operation is as follows:

[0059]Grinding the raw ore until the particle size is less than or equal to 0.074mm and accounting for more than 85% of the total mass of the raw ore, and then adjusting the slurry; obtaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com