Straw smashing process

A technological process and straw pulverization technology, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of high proportion of unqualified straw, high cost of pulverizing knives, and large number of knives used, so as to improve pulverization quality and reduce Equipment downtime and tool change time, the effect of reducing tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

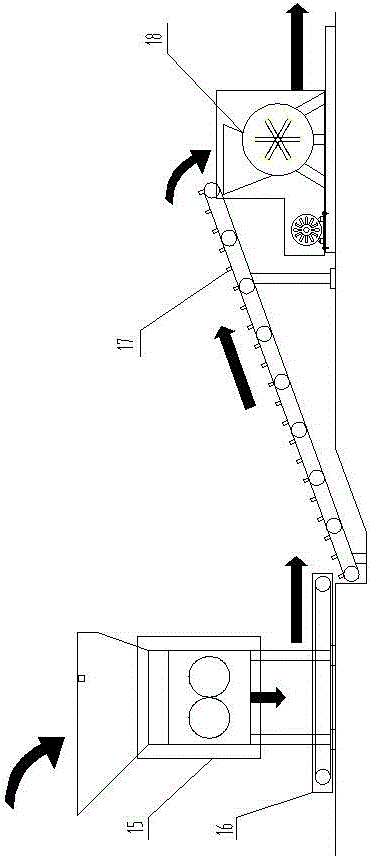

[0043] The key point of the present invention lies in the introduction of the straw pretreatment process, and it is designed as a combined crushing process; that is, for the situation of the straw, the crushing of the straw is realized through the combination of the double-stick crushing 15 and the pulverizer 18, and the double-stick crushing is the pretreatment machine. .

[0044] The straw crushing process scheme of the present invention includes the following steps: (1) straw pretreatment; (2) straw crushing treatment; solving the three low crushing problems of low crushing quality, low tool life, and low continuous operation capacity of equipment in the prior art scheme , to provide high-quality fermentation materials for the production of organic fertilizers.

[0045] Below in conjunction with specific embodiment the present invention is described in further detail:

[0046] Such as figure 1As shown, the straw coarse material first enters the straw pretreatment machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com