Quartz sand fuse and fabrication method thereof

A quartz sand and fuse technology, applied in fuse manufacturing, electrical components, circuits, etc., can solve problems such as poor explosion-proof performance, poor stability, and poor breaking capacity of fuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A quartz sand fuse of the present invention comprises an insulating tube, a first end cover, a second end cover, a first connecting terminal, a second connecting terminal and a melt, and a cavity axially penetrating through the insulating tube is opened in the insulating tube body, the first end cover is fixedly connected to one end of the insulating tube, the second end cover is fixedly connected to the other end of the insulating tube, and the first terminal is fixedly connected to the first end cover , the second connection terminal is fixedly connected to the second end cover, the melt is disposed in the cavity, the first connection terminal and the second connection terminal are respectively electrically connected to the melt, The insulating pipe is filled with a quartz sand composition, and the quartz sand composition wraps the melt, and at least one through hole communicating with the cavity is opened on the pipe wall of the insulating pipe.

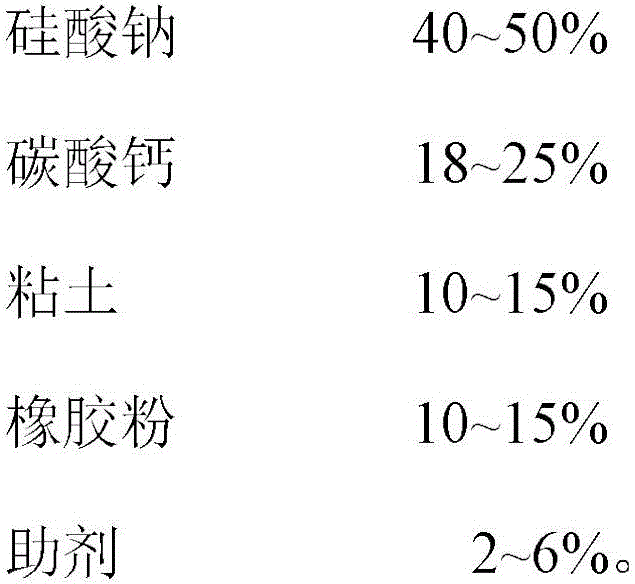

[0030] The quartz s...

Embodiment 2

[0044]A quartz sand fuse of the present invention comprises an insulating tube, a first end cover, a second end cover, a first connecting terminal, a second connecting terminal and a melt, and a cavity axially penetrating through the insulating tube is opened in the insulating tube body, the first end cover is fixedly connected to one end of the insulating tube, the second end cover is fixedly connected to the other end of the insulating tube, and the first terminal is fixedly connected to the first end cover , the second connection terminal is fixedly connected to the second end cover, the melt is disposed in the cavity, the first connection terminal and the second connection terminal are respectively electrically connected to the melt, The insulating pipe is filled with a quartz sand composition, and the quartz sand composition wraps the melt, and at least one through hole communicating with the cavity is opened on the pipe wall of the insulating pipe.

[0045] The quartz sa...

Embodiment 3

[0058] A quartz sand fuse of the present invention comprises an insulating tube, a first end cover, a second end cover, a first connecting terminal, a second connecting terminal and a melt, and a cavity axially penetrating through the insulating tube is opened in the insulating tube body, the first end cover is fixedly connected to one end of the insulating tube, the second end cover is fixedly connected to the other end of the insulating tube, and the first terminal is fixedly connected to the first end cover , the second connection terminal is fixedly connected to the second end cover, the melt is disposed in the cavity, the first connection terminal and the second connection terminal are respectively electrically connected to the melt, The insulating pipe is filled with a quartz sand composition, and the quartz sand composition wraps the melt, and at least one through hole communicating with the cavity is opened on the pipe wall of the insulating pipe.

[0059] The quartz s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com