Double layer conveying equipment wireless leakage detector and leakage detection system thereof

A technology of leak detector and storage equipment, applied in the direction of instruments, alarms, etc., can solve the problems of affecting detection, difficult installation, polluting the environment, etc., to achieve the effect of convenient maintenance or replacement and avoid harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

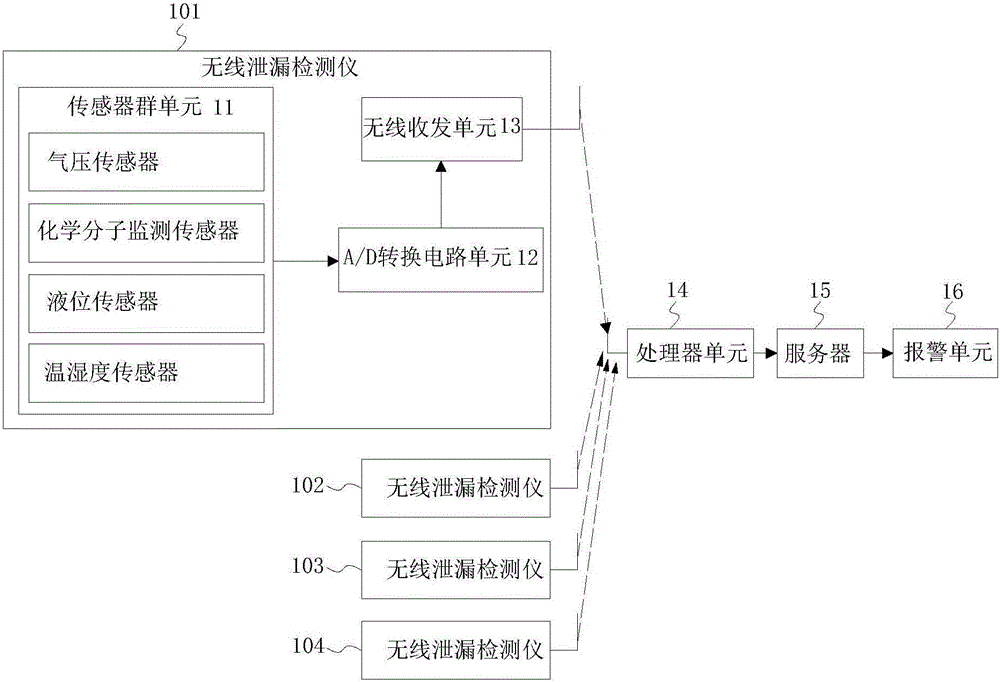

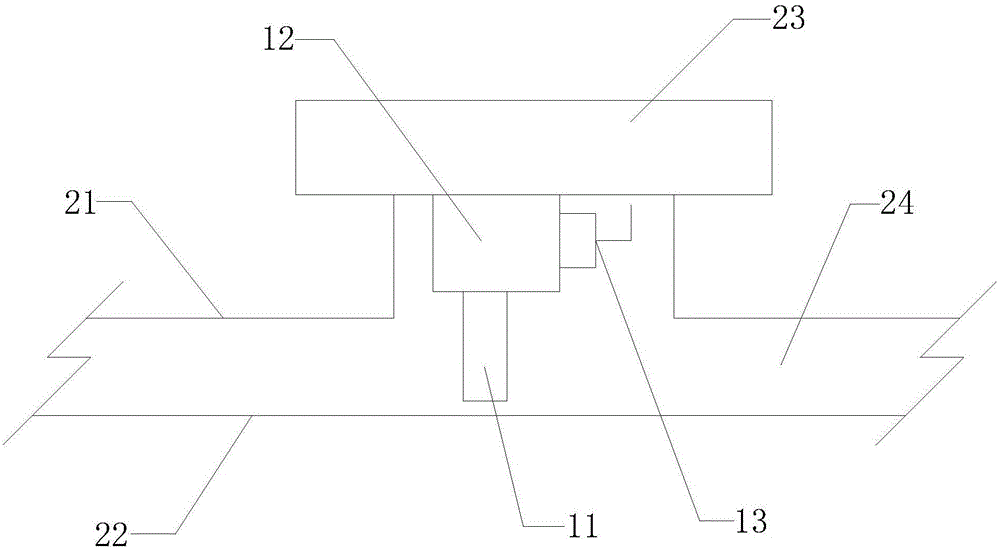

[0027] Such as figure 1 , 2 The present embodiment shown is a wireless leak detection system for a plurality of buried double-layer oil storage tanks in a gas station. Wireless leak detectors 101-104 are respectively installed on each double-layer oil storage tank. The layer 21 is provided with an opening to connect the gap layer 24 between the outer layer 21 and the inner layer 22 of the oil storage tank. The opening is sealed by a flange 23 , and its wireless leak detector is set in the gap layer 24 through the outer layer opening.

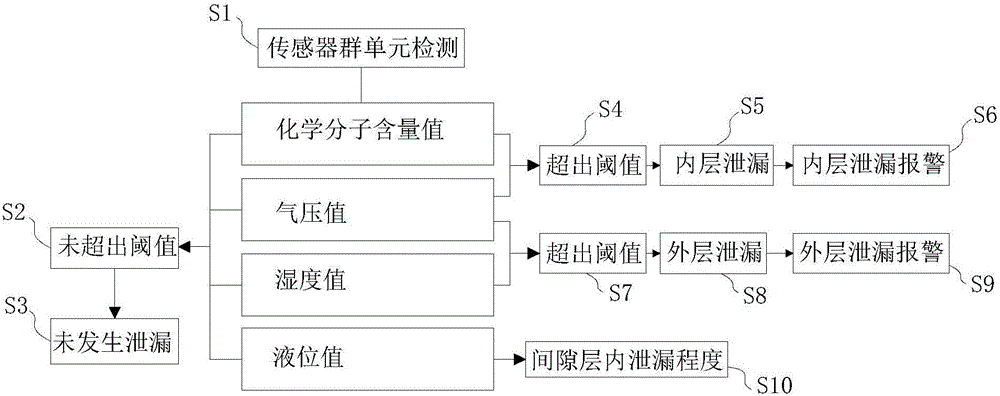

[0028] The wireless leak detectors 101 - 104 arranged in the gap layer 24 of the double-layer oil storage tank include: a sensor group unit 11 , an A / D conversion circuit unit 12 and a wireless transceiver unit 13 . The sensor group unit 11 of this embodiment includes: an air pressure sensor, a chemical molecule monitoring sensor, and a temperature and humidity sensor.

[0029] After the wireless leak detectors 101-104 are installed on the gap...

Embodiment 2

[0036] More and more oil and natural gas are transported by double-layer pipelines. This embodiment is a wireless leak detection system for double-layer pipelines. The pipeline transportation of oil and natural gas is multi-directional transportation, such as figure 1 , 2 As shown, a wireless leak detector is installed in each section of the double-layer pipeline, and the outer layer 21 of the double-layer pipeline is provided with an opening, which is connected with the gap layer 24 between the outer layer 21 and the inner layer 22 of the double-layer pipeline, and the opening is sealed by a flange 23 , the wireless leak detector is set in the gap layer 24 of the double-layer pipeline through the opening of the outer layer 21 .

[0037] The wireless leak detector set in the gap layer 24 of the double-layer pipeline includes: a sensor group unit 11 , an A / D conversion circuit unit 12 and a wireless transceiver unit 13 . The sensor group unit 11 in this embodiment includes: an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com