Traditional Chinese medicine percolation process control system and control method

A process control system and percolation technology, applied in control/regulation systems, liquid level control, non-electric variable control, etc., can solve the problems of waste of use in GMP workshops, poor quality controllability, and large fluctuations in process and product quality. , to achieve the effect of improving the quality stability, stability and uniformity assurance of traditional Chinese medicine products, and good quality batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

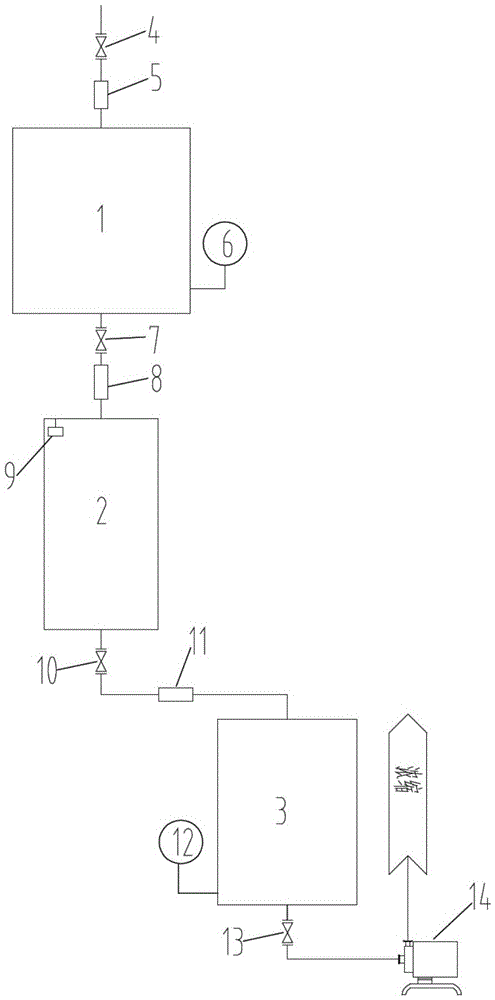

Method used

Image

Examples

Embodiment 1

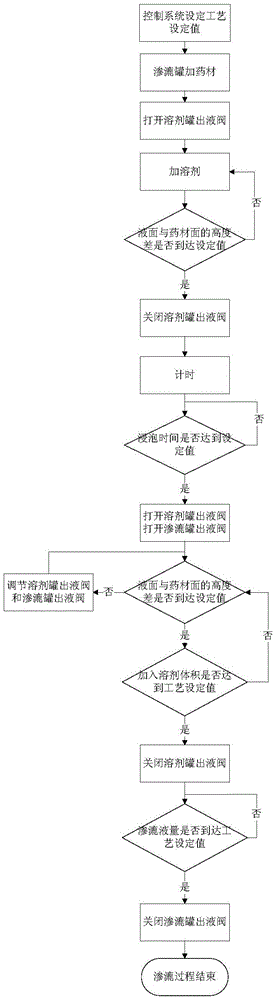

[0042] The method of using the traditional Chinese medicine percolation process control system is as follows:

[0043] (1) Set each process setting value on the control unit;

[0044] (2) Add Chinese herbal medicines in the percolation tank 2, open the solvent tank outlet valve 7 and add solvent to the percolation tank 2;

[0045] (3) The radar liquid level gauge 9 monitors the height difference between the liquid level of the percolation tank and the medicinal material surface. When reaching the process setting value, close the solvent tank outlet valve 7 and start timing. When the soaking time reaches the process setting value, Open the solvent tank outlet valve 7, open the percolation tank outlet valve 10;

[0046](4) Observe the height difference between the liquid level on the radar liquid level gauge 9 and the medicinal material surface, and when the height difference between the percolation solvent liquid level and the medicinal material surface in the percolation tank...

Embodiment 2

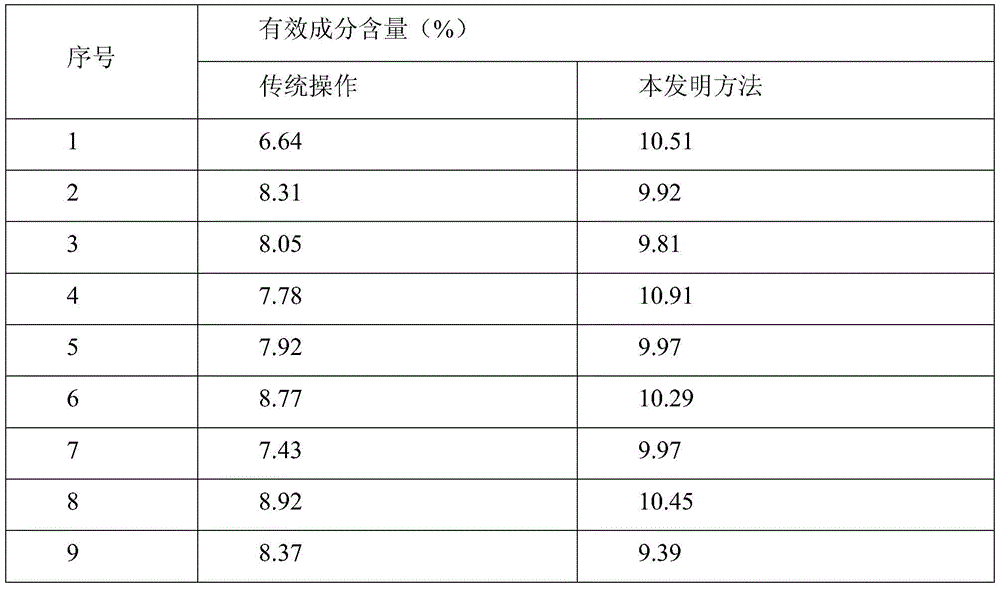

[0049] Control method of Panax notoginseng percolation process

[0050] (1) Get the net decoction pieces of Radix Notoginseng, cross 20 mesh sieves after pulverizing, get Radix Notoginseng powder, get two parts of Radix Notoginseng powder respectively, each 100kg, carry out Radix Notoginseng percolation according to traditional method and the method of the present invention respectively;

[0051] (2) Set each process setting value on the control unit:

[0052] The high liquid level of the solvent tank is 80%, and the low liquid level is 20%; the height difference between the liquid level and the medicinal material level in the percolation tank is 20-30cm; the soaking time is 3 hours;

[0053] (3) Add notoginseng powder in the percolation tank 2, open the solvent tank outlet valve 7 and add the percolation solvent to the percolation tank 2; the percolation solvent is 75% ethanol; the addition of the percolation solvent is 800L; The percolation volume is 700L; the percolation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com