Optical cable with external symmetrical reinforcements

A strength member, external technology, applied in the field of external symmetrical strength member optical cable, can solve the problems of inconvenient use of optical cable divergence, difficulty in cable stripping, increase of cable weight and raw material cost, etc., to achieve good indoor laying performance, excellent self-supporting Effects of aerial laying performance and convenient self-supporting aerial laying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

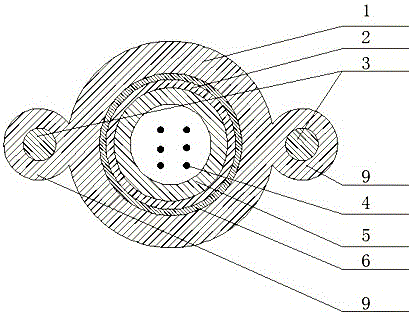

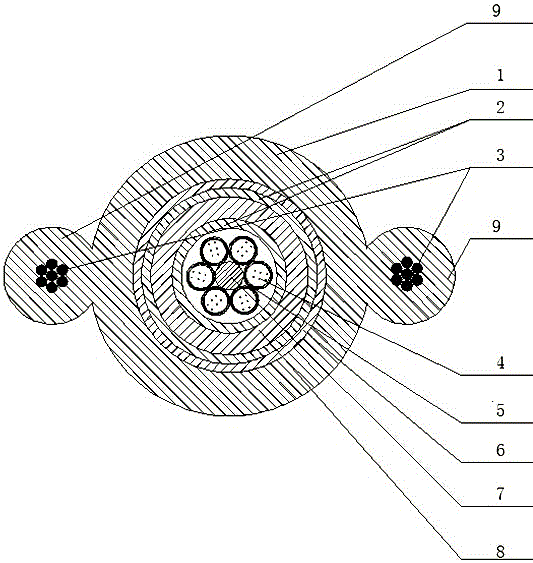

[0020] The first embodiment of the present invention is figure 1 As shown, there is a central tube type cable core, and the cable core includes a single loose tube 5, and an optical communication unit 4 is laid in the loose tube, and the optical communication unit can be an optical fiber, an optical fiber bundle, an optical fiber ribbon or a tight sleeve fiber; the cable core is coated with a water-blocking element 2, and the water-blocking element is a water-blocking yarn or a water-blocking tape; Cover the outer sheath. The outer sheath 1 with a circular cross-section is covered by the armor layer or the reinforcement layer, and outwardly protruding lugs 9 are arranged symmetrically on both sides of the outer periphery of the outer sheath, and the lugs on both sides are parallel, and the cross-section of the lugs is It is in the shape of a large semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com