A plasma source emission array based on microporous electrode structure

A technology of plasma and microporous electrodes, which is used in seismology in areas covered by water, can solve the problems of short electrode life, achieve long electrode life, improve electro-acoustic efficiency, and large bubble size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

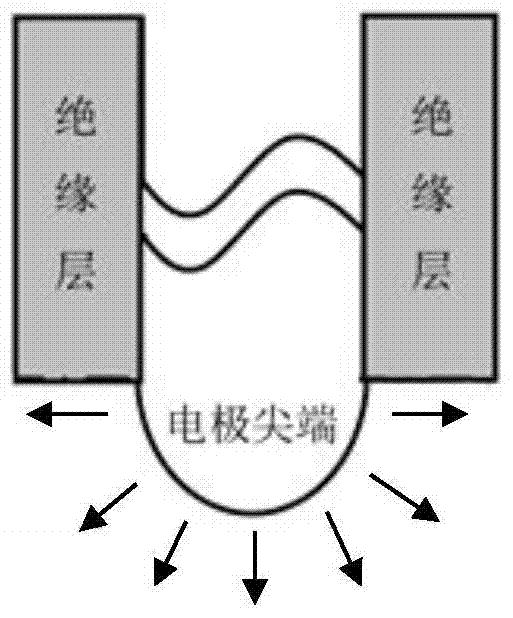

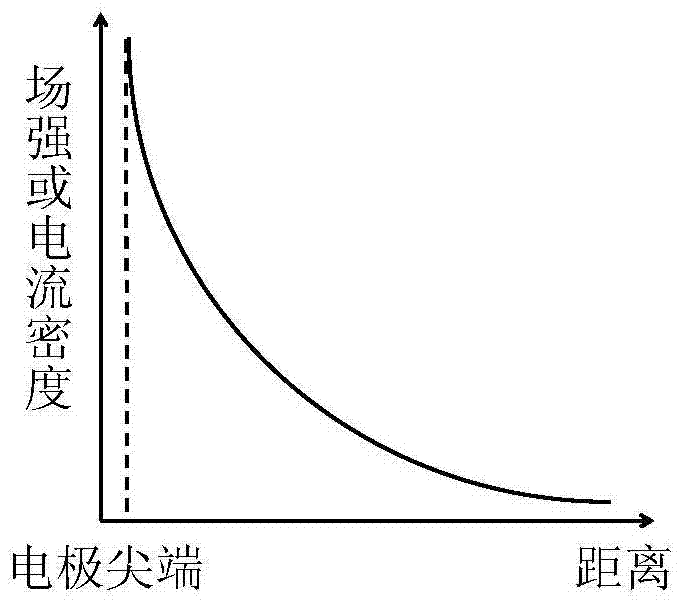

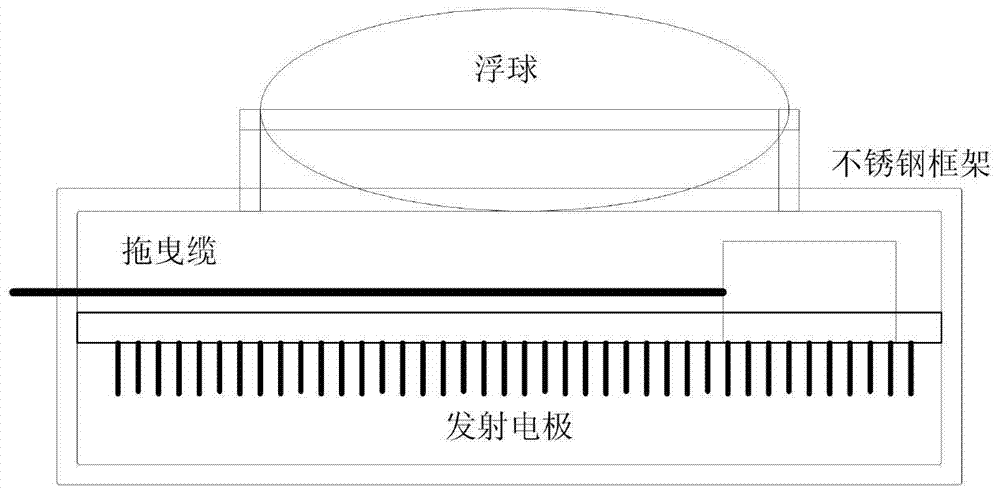

[0037] Figure 3, Figure 4 and Figure 5 These are three implementation modes of the present invention corresponding to the planar emission array, the cylindrical emission array and the spherical emission array. What all three structures have in common is that a porous insulating layer covers the high-voltage electrode and isolates it from the low-voltage electrode.

[0038]As shown in FIG. 3 , the planar emitting array is composed of a flat metal electrode 1 connected to a high voltage, a porous insulating layer 2 and a metal frame 3 connected to a low voltage, wherein the flat metal electrode 1 is embedded in the porous insulating layer 2 . The porous insulating layer 2 is divided into upper and lower parts according to the structure. The upper part is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com