Purifying, sterilizing, humidifying and dehumidifying all-in-one machine

An all-in-one machine and casing technology, applied in the directions of disinfection, deodorization, heating, etc., can solve the problems of low protection level of automatic water addition, difficult cleaning, high probability of water tank overflow, etc., to achieve outstanding substantive features, improve detection efficiency, Design Principles Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

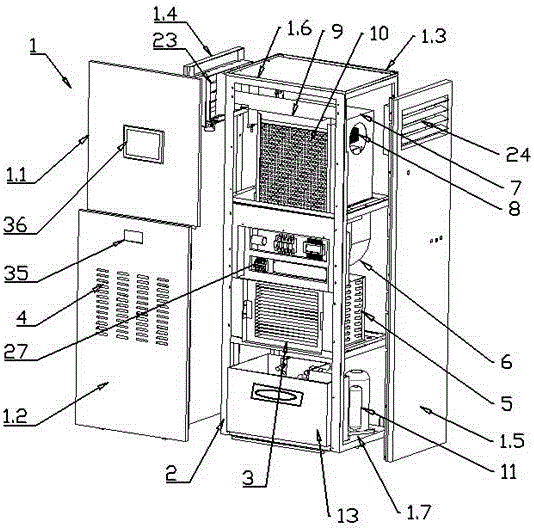

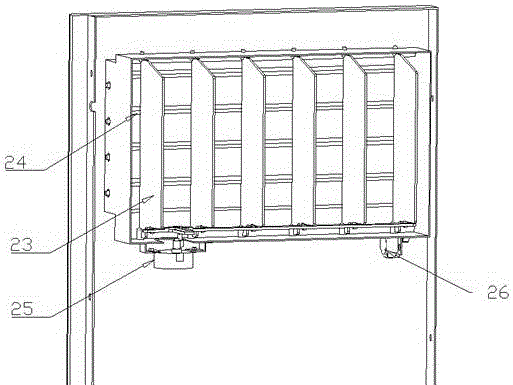

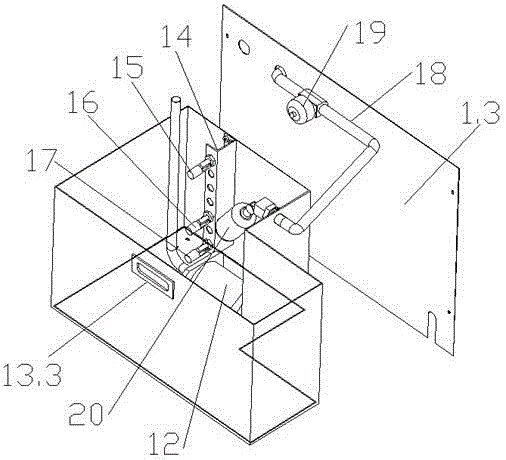

[0040] like Figures 1 to 5 As shown, a purification, disinfection, humidification and dehumidification integrated machine provided by the present invention includes a casing 1, and a frame 2 is arranged in the casing 1; an electronic dust collector 3 is arranged in the frame 2, and the The inlet end of the electronic dust collector 3 corresponds to the dust-proof air inlet 4 provided on the front lower cover of the casing, the outlet end of the electronic dust collector 3 is connected to the evaporation and condensation assembly 5, and the evaporation and condensation assembly 5 A compressor 11 is connected, and the evaporating and condensing assembly 5 is also connected to an air duct 7 through a fan 6. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com