Self-operated balance valve

A self-operated balancing valve and valve body technology, used in balancing valves, safety valves, valve devices, etc., can solve the problems of unadjustable spring preload, scaling on the spring surface, reduced sensitivity, etc., to achieve convenient debugging and service life. The effect of prolonging and improving the adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

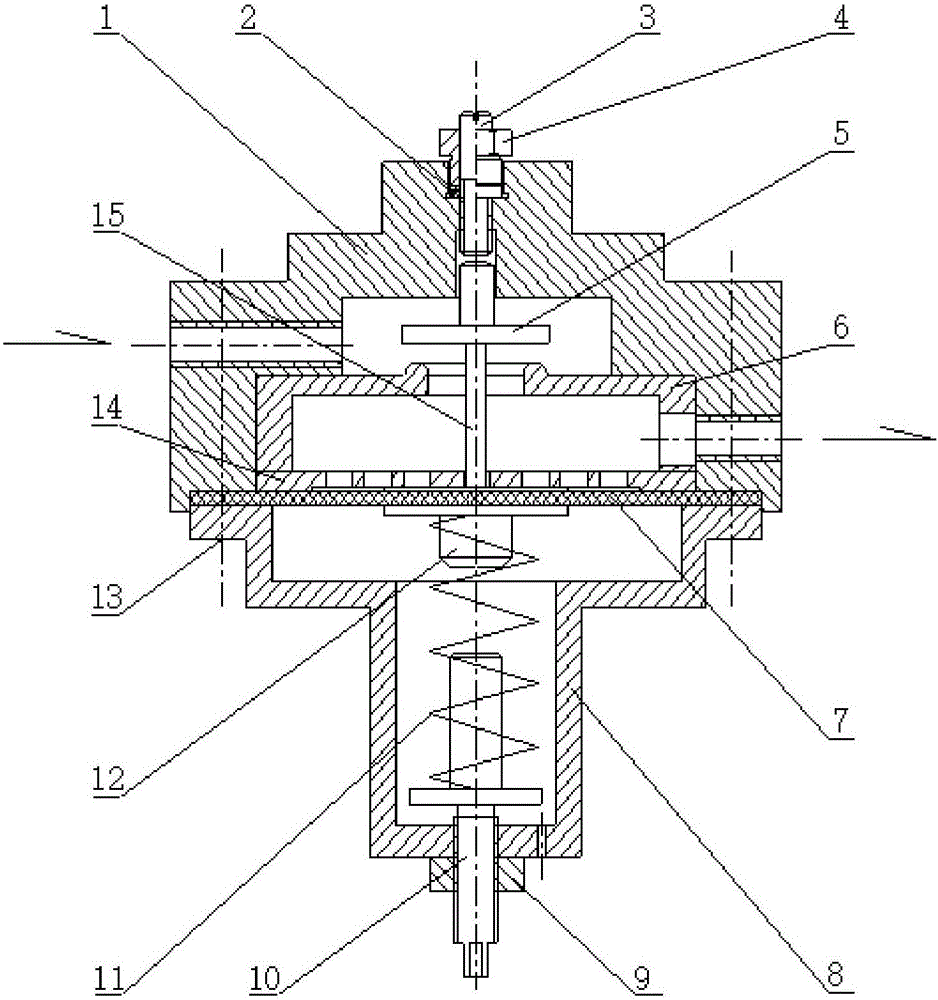

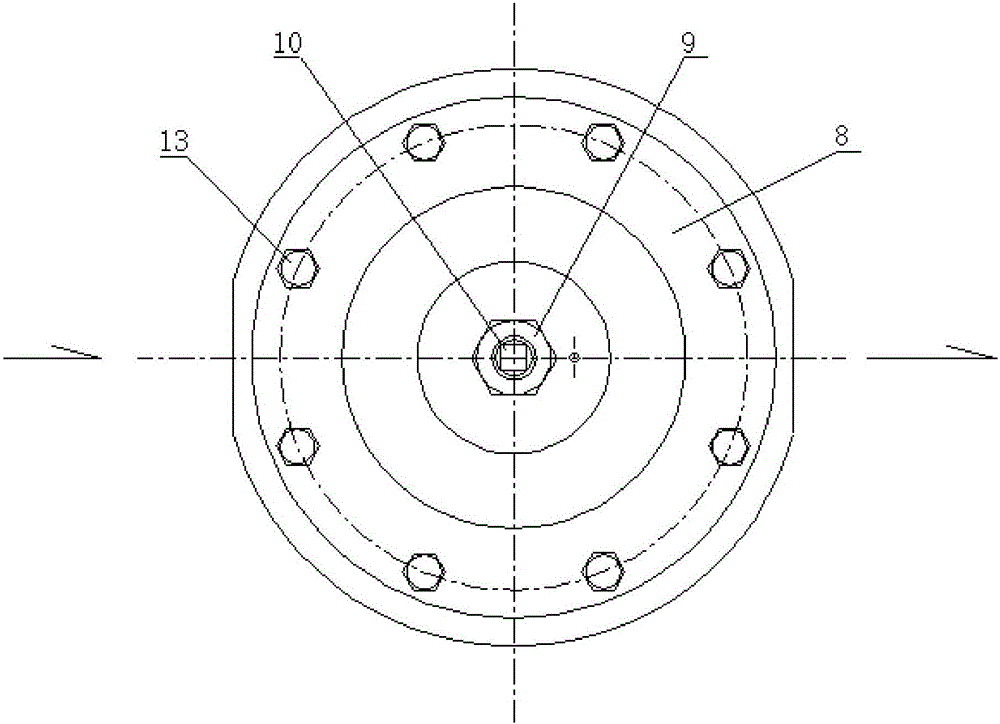

[0012] The valve body (1) is in the shape of a multi-step circular platform made of metal materials. The circumference of the large steps is provided with symmetrical parallel planes. One side plane is provided with a threaded through hole connected to the water inlet pipe, and the other side plane is provided with a threaded hole connected to the water outlet pipe. The inner cavity of the valve body (1) is a three-layer stepped hole, the bottom layer is connected to the threaded hole connected to the water inlet pipe; the middle layer is connected to the threaded hole connected to the water outlet pipe, and the diameter of the cavity is the same as that of the valve seat (6) and the baffle (14) The outer circle is excessively fitted; the cavity diameter of the outermost large step is matched with the large end of the bonnet (8) and the outer circle of the diaphragm (7); the center of the small end of the valve body (1) is provided with a threaded hole, and the outer side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com