Round valve

A round valve and round technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of insufficient air leakage, difficult operation, and difficult processing by workers who make products, and achieve the effect of convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

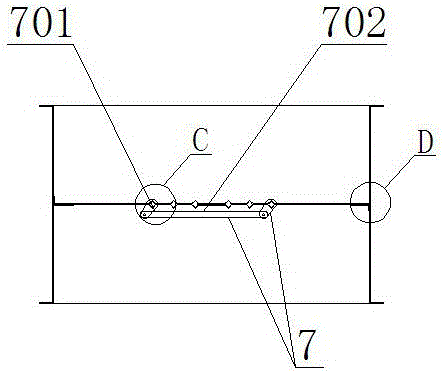

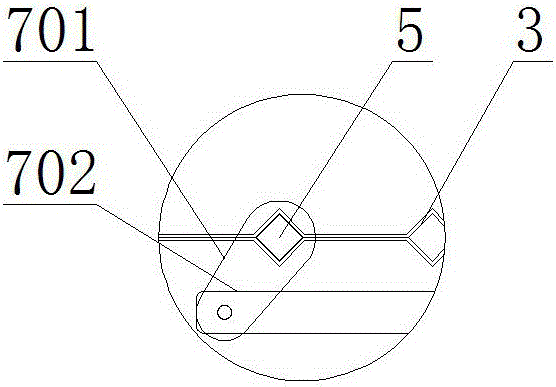

[0018] Below in conjunction with accompanying drawing, the present invention is further described;

[0019] In the accompanying drawings, a round valve includes a circular outer frame 1, an actuator 2 and blades 3, a tension spring 101 is connected between the circular outer frame 1 and the blades 3, and the circular outer frame The transverse section of 1 is "◎" shape, the purpose is to facilitate the processing and manufacturing, reduce the welding process, and have higher structural strength. The circular outer frame 1 is provided with an intermediate bracket 4 and a boss 102. The circular The connection between the outer frame 1 and the boss 102 is a riveting connection, and the connection with the intermediate support 4 is also a riveting connection. The purpose is to reduce the welding process and prevent thermal deformation. The intermediate support 4 and the A first seal 103 is provided between the circular outer frame 1, a second seal 104 is provided on the blade 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com