Size adjustable type material lifting device and construction method of size adjustable type material lifting device

An adjustable and material-based technology, applied in building construction, building material processing, construction, etc., can solve problems such as poor adaptability and low efficiency, achieve high durability, reduce costs, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

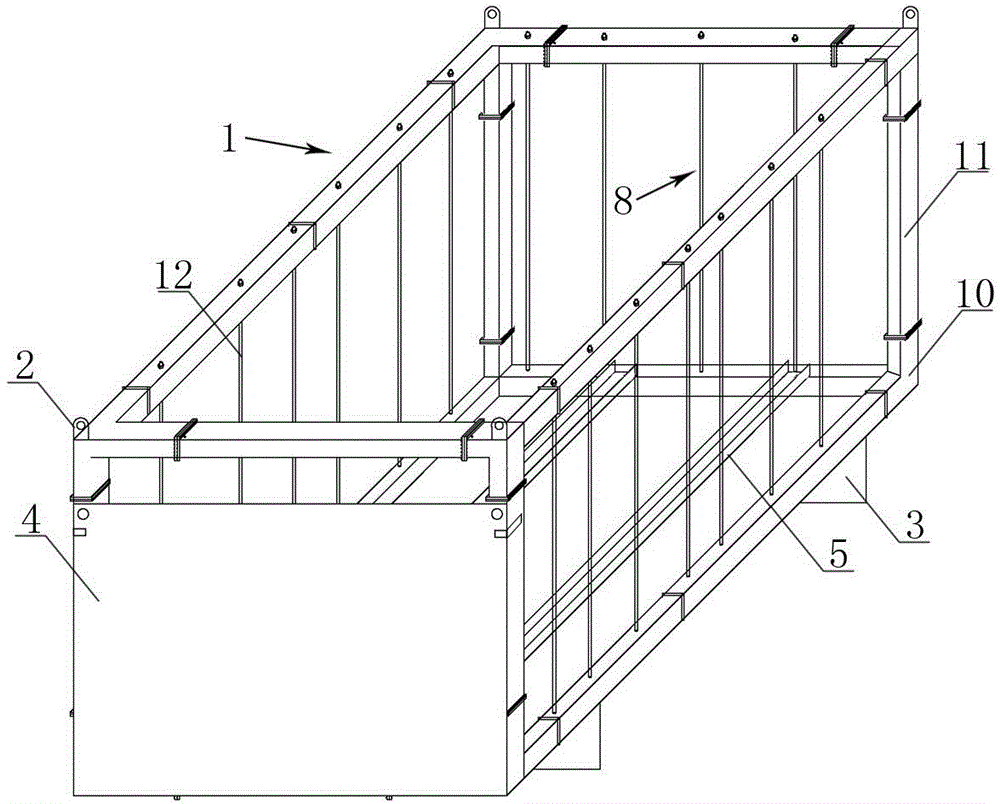

[0034] Examples see figure 1 As shown, this size-adjustable material lifting device includes a frame body 1 and lifting lugs 2 connected to the frame body 1, the bottom of the frame body 1 is connected with a base 3, and the frame body 1 is made of steel or Made of aluminum alloy.

[0035] The frame body 1 is a three-dimensional frame composed of eight transfer nodes 10 and at least eight connecting rods 11, wherein the transfer nodes 10 are located at eight corner positions of the frame body 1, including three mutually perpendicular The connecting joint rods 11 are respectively connected between adjacent joint heads, and the ends of the transition nodes 10 and the connecting joint rods 11 are connected with connecting plates, and the adjacent connecting plates are connected by bolts.

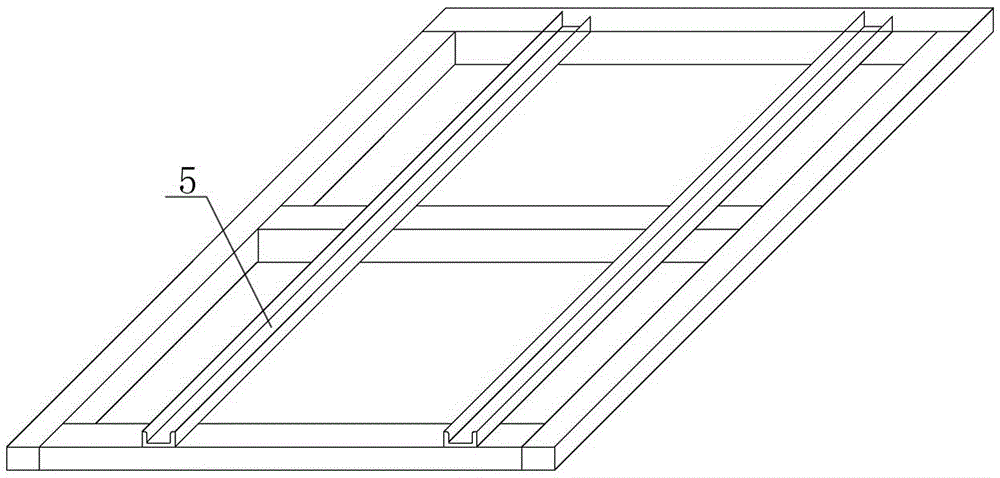

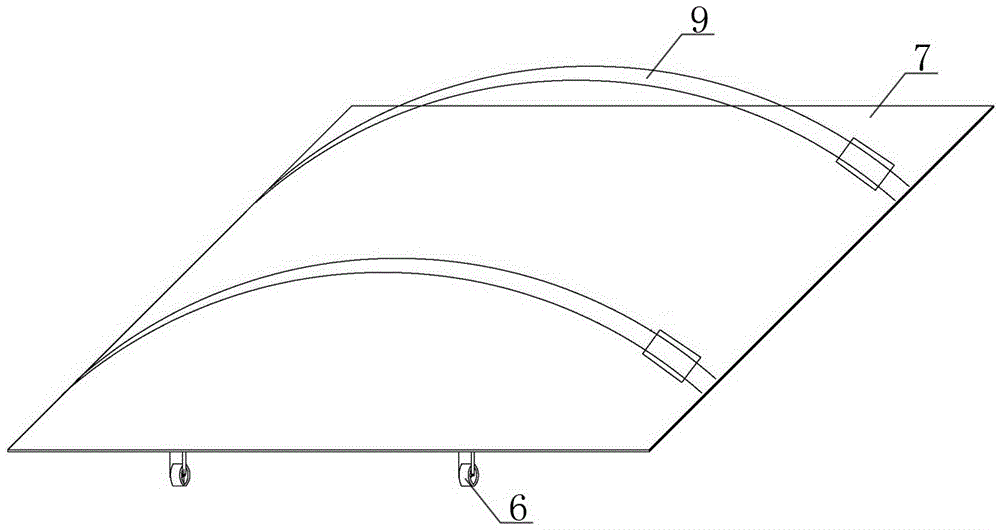

[0036] A fixed flap 4 is hinged on the side of the frame body 1 located at the front side of the guide rail, and guardrails 8 are connected between the opposite connecting joints on the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com