Wharf structure suitable for silt coast and construction method of wharf structure

A construction method and silt-based technology, which can be used in sea area engineering, coastline protection, pier, etc., can solve the problems of high cost of ship machinery, large impact of wind and waves, etc., and achieve the goal of increasing land area, reducing engineering quantity, and fast construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

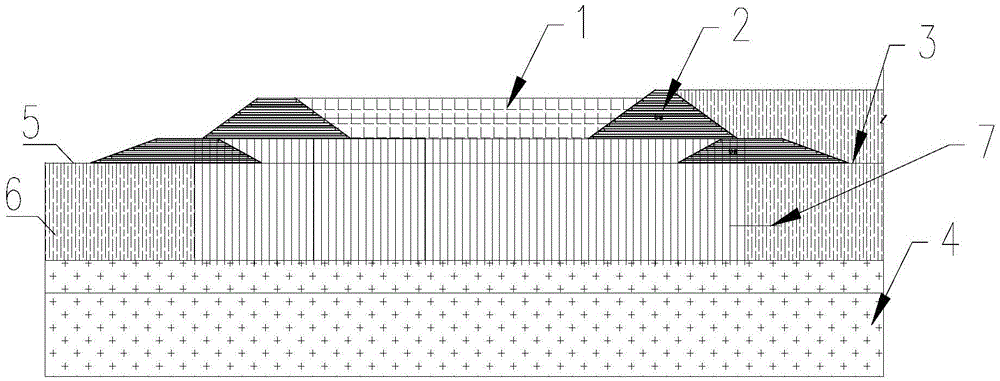

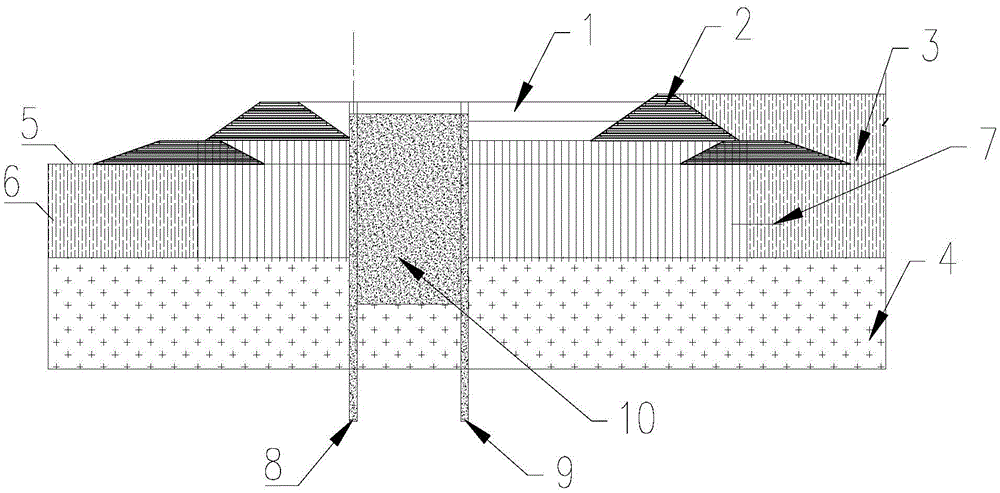

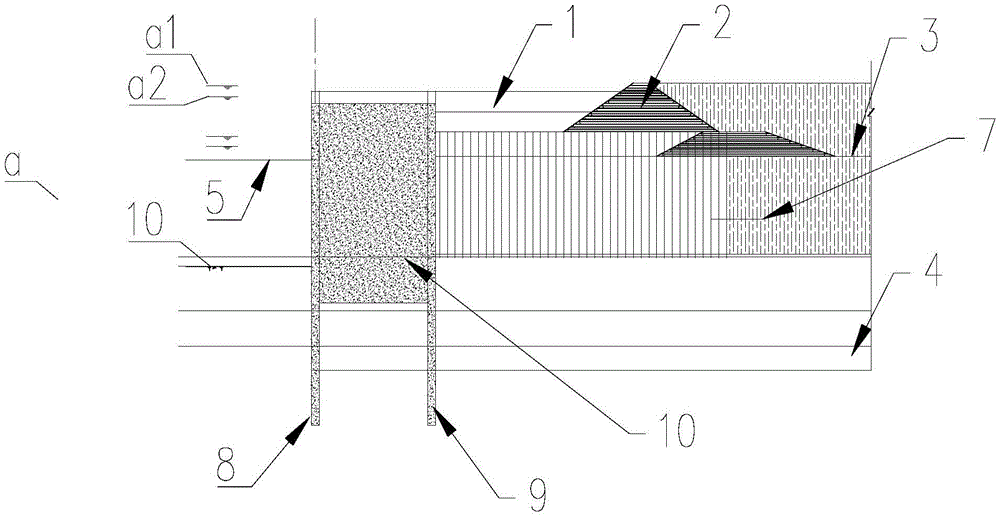

[0033] The wharf structure applicable to the muddy coast of this embodiment: please refer to Figure 1-Figure 6 As shown, the front direction is the direction close to the sea, and the rear direction is the direction relatively away from the sea. The wharf structure includes:

[0034] Causeway 1, sand quilt 2 such as Figure 1-4 Shown, can find out natural mud surface 3 and 5, clay layer 4 and silt layer 6 position from above-mentioned figure;

[0035] The front connecting wall 8, the rear connecting wall 9, and the partition wall 10 arranged on the embankment 1: Among them, the partition wall 10, the front connecting wall 8 and the rear connecting wall 9 form a box-tube structure, and the box-tube structure The wharf structure can control the absolute horizontal displacement and vertical bearing capacity of the structure by using the overall stiffness of the cylinder and the depth of the soil. It can not only meet the retaining soil by expanding the plane scale, but also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com