Construction method for cable trough and protective shoulder of high-speed railway roadbed

A technology for high-speed railways and construction methods, which is applied in the installation of cables, ground cables, roads, etc. It can solve the problems of large cutting flying dust, low efficiency, and difficult cutting work, and achieves reduced engineering investment, convenient construction, and small consumables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the drawings and embodiments:

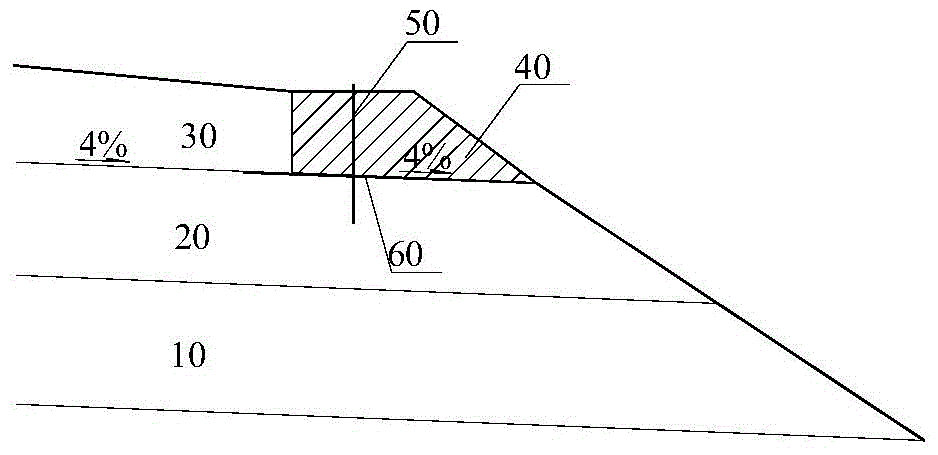

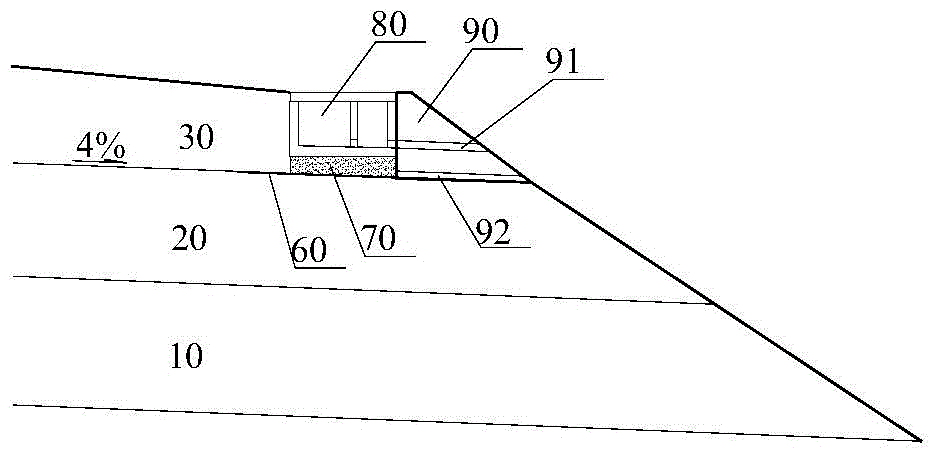

[0013] Reference figure 1 , figure 2 and image 3 , The construction method of a high-speed railway subgrade cable trough and shoulder guard of the present invention, the steps are:

[0014] 1) Fill the road basic body structure 10 and the road base layer structure 20 in layers with a thickness of 0.3m;

[0015] 2) Rolling the top surface of the base layer structure 20 to form a 4% outward lateral drainage slope;

[0016] 3) Lay a composite anti-drainage board 60 on the top surface of the road base structure 20 at the corresponding positions of the cable trough 80 and the shoulder guard 90, and its width extends 0.2m into the inner side of the road base surface structure 30;

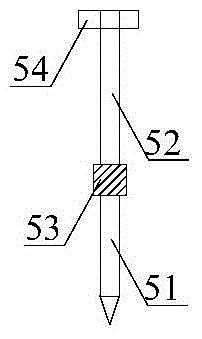

[0017] 4) Place a shoulder mold 40 on the composite waterproof and drainage board 60 at the corresponding positions of the cable groove 80 and the shoulder guard 90. The shoulder mold 40 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com