Rubber damping rubber gasket combined structure of engine suspension

A technology of rubber shock absorption and combined structure, which is applied in the direction of springs/shock absorbers, mechanical equipment, power devices, etc., can solve the problems of poor spring consistency, large number of parts, poor consistency, etc., and achieve large internal friction and damping, absorption Strong vibration ability and good consistency control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

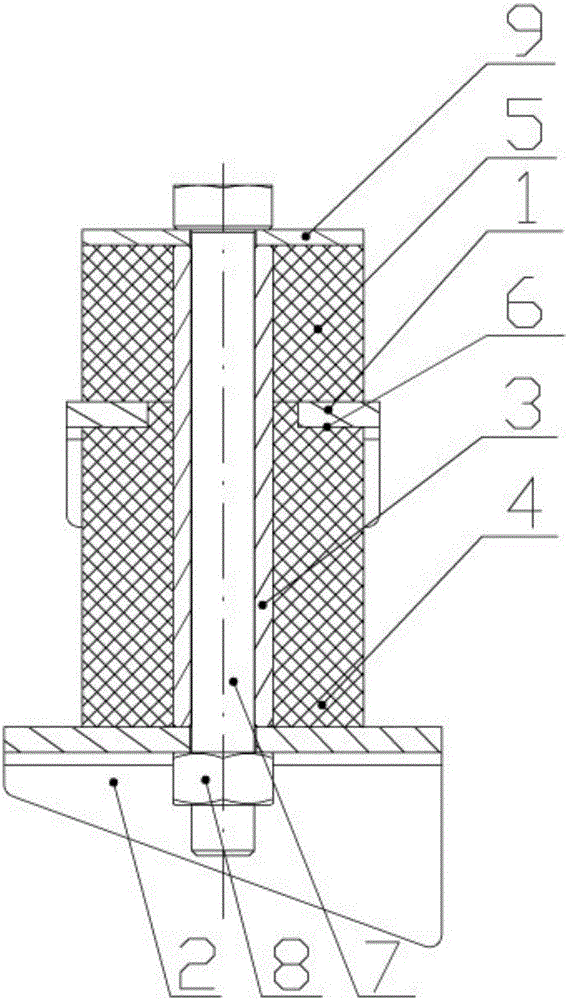

[0014] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] Refer to attached figure 1 , the present invention includes a rubber shock-absorbing rubber pad body, the rubber shock-absorbing rubber pad body is a pure rubber structure, so the rubber shock-absorbing rubber pad body can freely determine the shape, and the rubber shock-absorbing rubber pad body can be controlled by adjusting the rubber formula components The hardness of the rubber shock-absorbing rubber pad body can meet the requirements of stiffness and strength in all directions, and the size of the rubber shock-absorbing rubber pad body can also be controlled, so that the structure of the rubber shock-absorbing rubber pad body is more optimized and reasonable, and the application range is wider. The consistency control is better; compared with the metal spring, the elastic modulus of the pure rubber structure is mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com