Pot stretcher

A technology of stretching machine and pot body, which is applied to other household appliances, household appliances, applications, etc., can solve the problems affecting the pot body stretching quality and stretching efficiency, poor working stability, and unbalanced blank-holding force, etc., to achieve Simple structure, stable blank holder force and stable compensation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

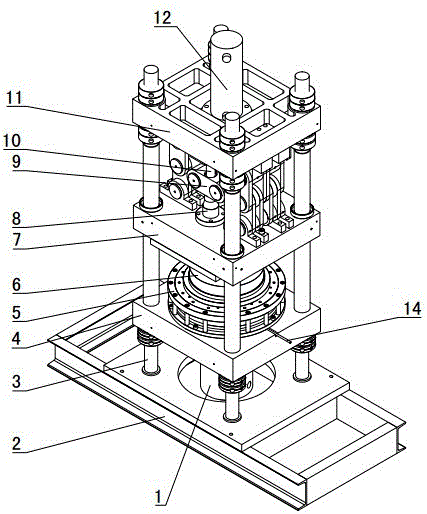

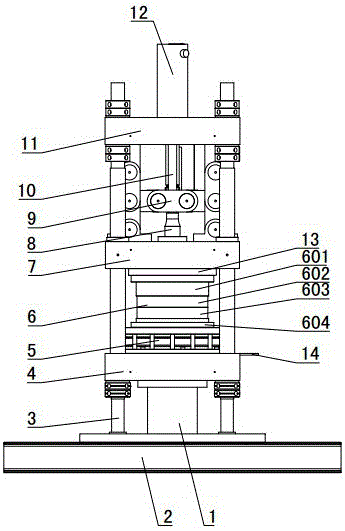

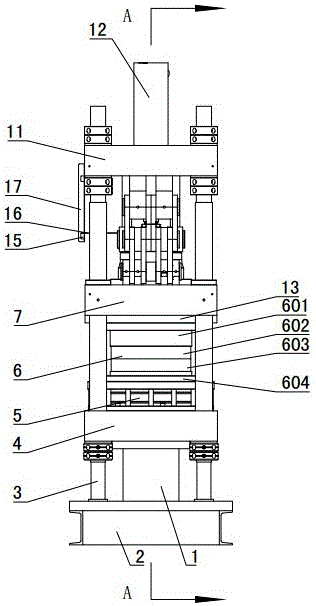

[0029] Figure 1~5 It is the best embodiment of the present invention. Figure 1~5 The present invention will be further explained.

[0030] A pan stretching machine includes a blank holder cylinder 12 and a stretching cylinder 1. A stretching die 6 is arranged between the blank holder cylinder 12 and the stretching cylinder 1. The stretching die 6 includes an upper blank holder 602 and a lower press The edge ring 603 and the stretching head 605, the blank holder cylinder 12 is arranged above the upper blank holder 602 to push the upper blank holder 602 down, and the stretching cylinder 1 is arranged below the stretching head 605 to push the stretching head 605 up, down The blank holder 603 is installed above an elastic support mechanism. After the upper blank holder 602 and the lower blank holder 603 are closed, the elastic support mechanism compensates the blank holder force through the deformation restoring force. The pot body stretching machine stretches the circular sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com