Nanosheet containing noble metal and preparation method thereof

A nanosheet and precious metal technology, applied in the field of catalysis, can solve the problems of slow reaction rate, many by-products, complicated steps, etc., and achieve the effects of easy operation, low cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] H 1.07 Ti 1.73 O 4 •H 2 Preparation of nanosheets

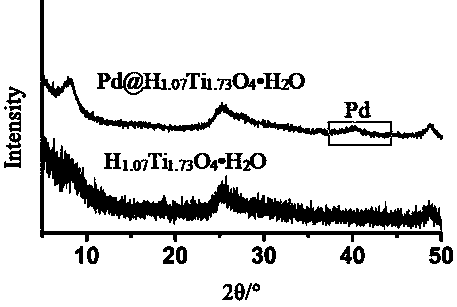

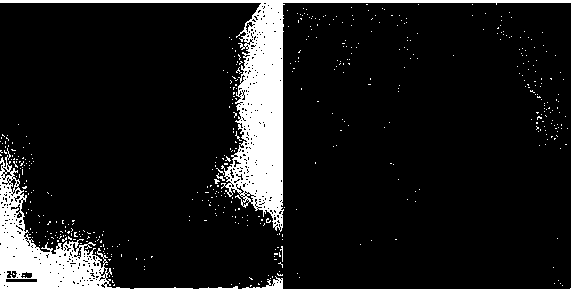

[0025] Set the molar ratio of 2.4:0.8:10.4 to K 2 CO 3 , Li 2 CO 3 And TiO 2 After grinding uniformly, place it in a corundum crucible, calcinate at 800℃ for 2 h, cool to room temperature, grind again, and calcinate at 1000 ℃ for 20 h, repeat once; obtain layered K 0.80 Ti 1.73 Li 0.67 O 4 , Take 10 g obtained K 0.80 Ti 1.73 Li 0.67 O 4 The sample is added to 1000 ml, 1 mol / L hydrochloric acid solution and stirred, and the acid is changed every 24 h. After 4 days, it is washed with deionized water to neutrality and dried at 60 ℃, which is a layered H 1.07 Ti 1.73 O 4 •H 2 O; The above layered H 1.07 Ti 1.73 O 4 •H 2 O and TBAOH (tetrabutylammonium hydroxide) (40 wt%) solution were mixed at a molar ratio of 1:1, magnetically stirred for 15 days, centrifuged at 3000 rpm, and the unstripped layer was removed to obtain H 1.07 Ti 1.73 O 4 •H 2 O nanosheet sol, 1 mol / L hydrochloric acid was added dropwise under ultrasonic conditio...

Embodiment 2

[0029] Pd@H 1.07 Ti 1.73 O 4 •H 2 O nanosheets catalyze the hydroxylation of phenol to produce cyclohexanone under light induction.

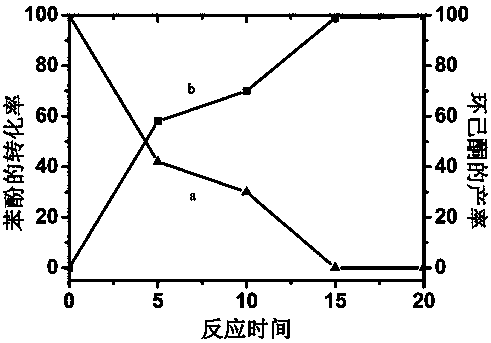

[0030] Pd@H will be prepared 1.07 Ti 1.73 O 4 •H 2 O nanosheets are used as catalysts to achieve the hydroxylation of phenol under light induction to prepare cyclohexanone. Weigh 20 mg nanosheets and 100 mg silicotungstic acid, vacuumize to exhaust the air, add 2 mL purified water and 10 μL phenol. In H 2 Stir under conditions, then turn on the light source for photocatalytic reaction. The product is detected by gas chromatography; the light source used in the experiment is a 300 W xenon lamp; the conversion of phenol and the production of products are as follows image 3 As shown, it can be seen from the figure that when there is a catalyst, the conversion rate of aniline reaches 100% after 15 hours of light (curve a), and the yield of cyclohexanone reaches more than 99% (curve b). Or without light or with H 1.07 Ti 1.73 O 4 •H 2 Under the conditio...

Embodiment 3

[0032] M@H 1.07 Ti 1.73 O 4 •H 2 O(Au,Pd,Pt) nanosheets were prepared and used as a catalyst to photodehydrate water to produce hydrogen.

[0033] Preparation method: H 1.07 Ti 1.73 O 4 •H 2 Disperse the O nanosheets in 22 mL deionized water, and stir ultrasonically until they are evenly dispersed; under stirring, the HAuCl 4 • 4H 2 O, H 2 PtCl 6 • 6H 2 O or Pd(NO 3 ) 2 • 2H 2 The O solution was added dropwise to the solution, and 10 mL of methanol solution was added, nitrogen gas was added for 0.5 h, UV light was irradiated for 3-5 h, filtered, washed and dried to obtain M@H 1.07 Ti 1.73 O 4 •H 2 The loading amount of M in O(M=Au,Pd,Pt) is converted according to the optimal amount of 1wt%. From Figure 4 It can be seen that the synthesized catalyst has a strong SPR characteristic absorption peak.

[0034] Precious metals that will be prepared @H 1.07 Ti 1.73 O 4 •H 2 O(Au, Pt) nanosheets are catalysts for photolysis of water to produce hydrogen. Add 80 mg of catalyst to 72 mL of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com