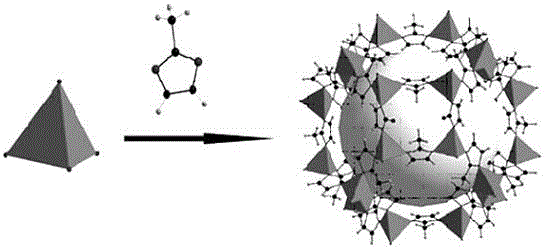

MOF type hierarchical porous material IPD-mesonMOF-12

A multi-level pore and mesoporous technology, applied in the fields of alkali metal oxides/hydroxides, inorganic chemistry, water/sludge/sewage treatment, etc., can solve the problem of unfavorable mesopores of surfactants, clear clogging, and thermal stability No problem, etc., to achieve good lipophilic hydrophobicity, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

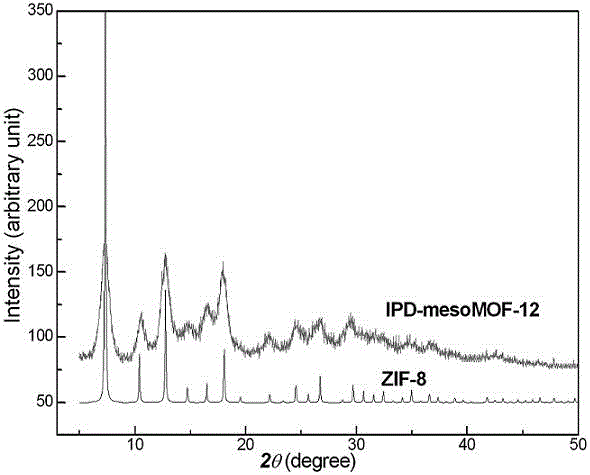

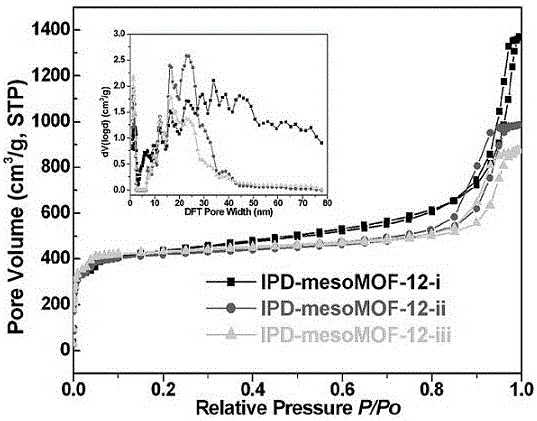

[0039] 1.188 g (4mmol) Zn(NO 3 ) 2 6H2O and 0.656 g (8 mmol) of Hmim were added to 18 mL of absolute ethanol, and 8 mmol of sodium hydroxide was added to stir at room temperature, then transferred to a 20 mL capacity polytetrafluoroethylene reactor and sealed at 100 ° C for 6 hours. After cooling to room temperature, the jelly-like substance was dried at room temperature to form a dry gel, and then it was extracted and washed with absolute ethanol for 7 hours with a Soxhlet extractor. Remove the residual ethanol under vacuum (0.2mmHg) at 150°C to obtain the MOF-type hierarchical porous material of the present invention, with a yield of 96% (calculated by Hmim), figure 2 It is the X-ray diffraction pattern of the MOF type hierarchical porous material synthesized, and the nanoparticle particle size is less than 60nm, and Fig. 3 is the scanning electron microscope (SEM) picture of the MOF type hierarchical porous material synthesized, micropore (1.1nm) and mesoporous ( 35nm), ...

Embodiment 2

[0043] 1.188 g (4mmol) Zn(NO 3 ) 2 6H2O and 10mmol Hmim were added to 18mL of absolute ethanol, and 10mmol of sodium hydroxide was added, stirred evenly at room temperature, then transferred to a 20ml-capacity polytetrafluoroethylene reactor and sealed at 120°C for 6 hours. After cooling to room temperature, the jelly-like substance was dried at room temperature to form a dry gel, and then it was extracted and washed with absolute ethanol for 7 hours with a Soxhlet extractor. Remove the residual ethanol under vacuum (0.2mmHg) at 150°C to obtain the MOF type hierarchical porous material of the present invention, the yield is 97% (calculated by Hmim), the particle size of nanoparticles is less than 60nm, micropore (1.1nm) and mesoporous (35nm) , BET specific surface 1670M 2 / g, total pore volume 1.54cm 3 / g, mesopore volume 1.03cm 3 / g.

Embodiment 3

[0045] 1.188 g (4mmol) Zn(NO 3 ) 2 6H2O and 0.656 g (8 mmol) of Hmim were added to 15 mL of absolute ethanol, and 8 mmol of sodium hydroxide was added to stir evenly at room temperature, then transferred to a polytetrafluoroethylene reactor with a capacity of 20 mL and sealed at 120°C for 6 hours. After cooling to room temperature, the jelly-like substance was dried at room temperature to form a dry gel, and then it was extracted and washed with absolute ethanol for 7 hours with a Soxhlet extractor. Remove the residual ethanol under vacuum (0.2mmHg) at 150°C to obtain the MOF type hierarchical porous material of the present invention, the yield is 97% (calculated by Hmim), the particle size of nanoparticles is less than 60nm, micropore (1.1nm) and mesoporous (35nm) , BET specific surface 1660M 2 / g, total pore volume 1.47cm 3 / g, mesopore volume 0.97cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com