A kind of fluid mixing method and high-speed centrifugal fluid mixing device

A fluid mixing and high-speed centrifugation technology, used in mixers, chemical instruments and methods, transportation and packaging, etc., can solve problems such as the inability to meet technical development requirements, improve mixing efficiency and dispersion quality, promote mixing quality, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

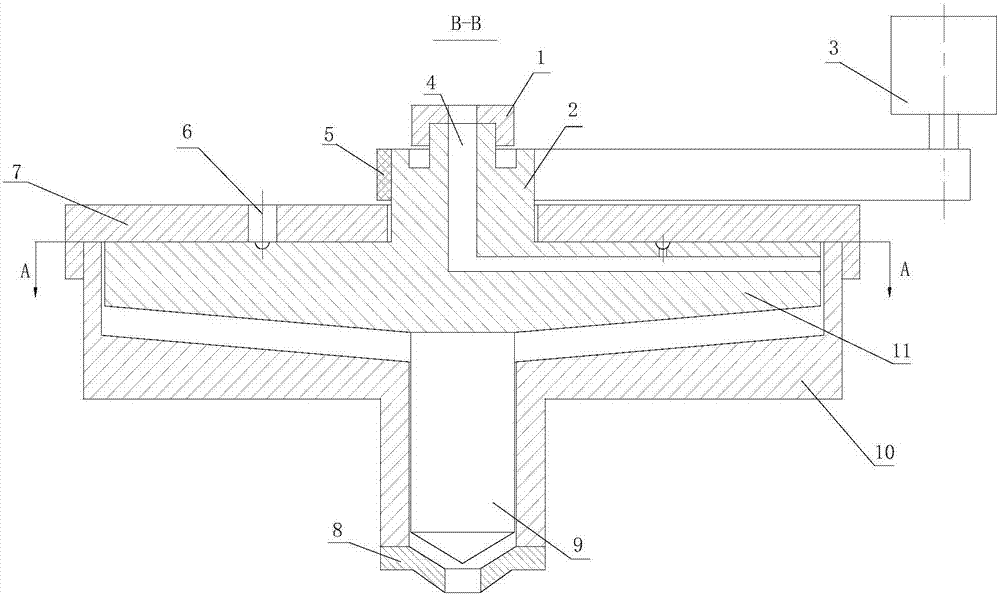

[0011] The specific implementation of the high-speed centrifugal fluid mixing device of the present invention will be described below with reference to the accompanying drawings.

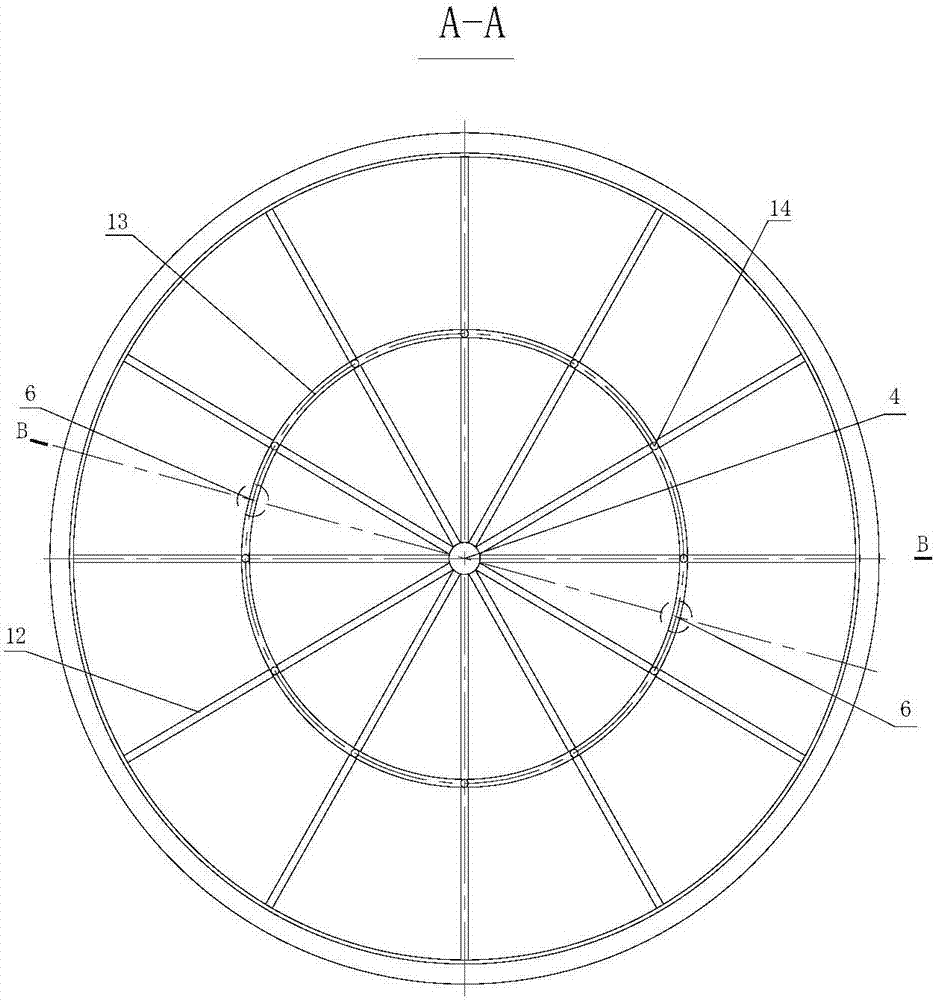

[0012] (1) The transmission pipeline of component A is externally connected to the rotary joint 1, and introduced through the middle hole 4, and then flows into such as figure 2 Twelve radial flow channels 12 are shown.

[0013] (2) The synchronous belt pulley 2 is coaxial with the rotary joint, and the synchronous belt 5 is installed on it, and is connected with the frequency conversion motor 3 to provide torque to the device. After starting the motor, the high-speed rotation of the centrifugal shear mixing disc is realized.

[0014] (3) Turn on the fluid pulse jet pump, use the pulse pressure to make the B component pass through the two large holes 6 provided on the cover plate 7, enter the annular flow channel 13 provided on the centrifugal shear mixing disc, and then pass through the small hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com