ELECTRIC PRESSURE RICE COOKER, AUTO LOCKING DEVICE, automatic pressure locking function control method

A pressure and rice cooker technology, applied in pressure cookers and other directions, can solve the problems of abnormal operation of the motor, large damage to components, no pressure lock or failure to release the pressure lock, etc., to prevent failures and prevent magnetic force from weakening. , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

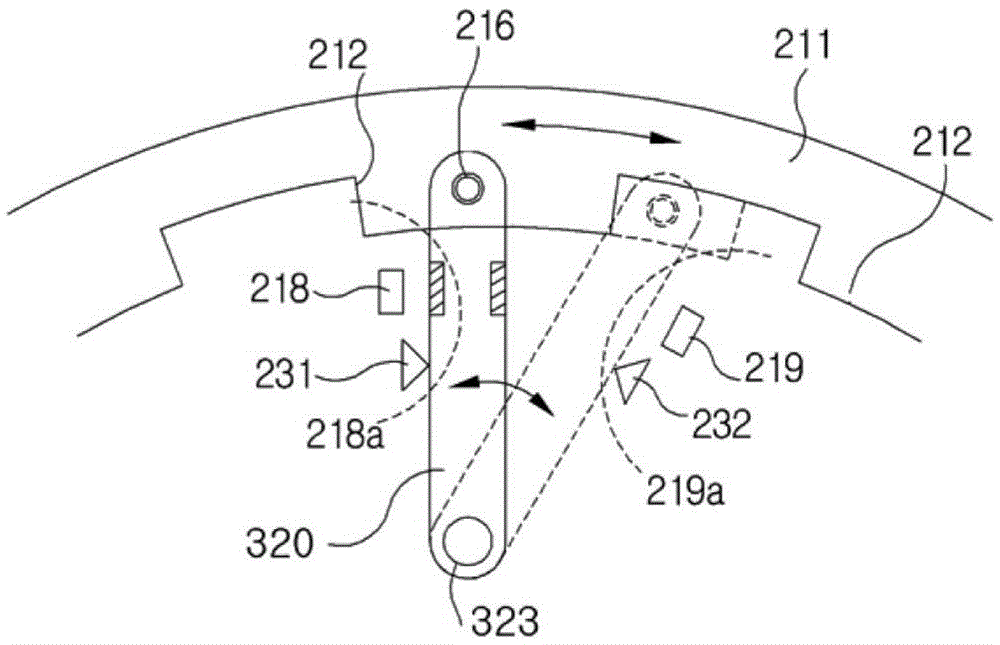

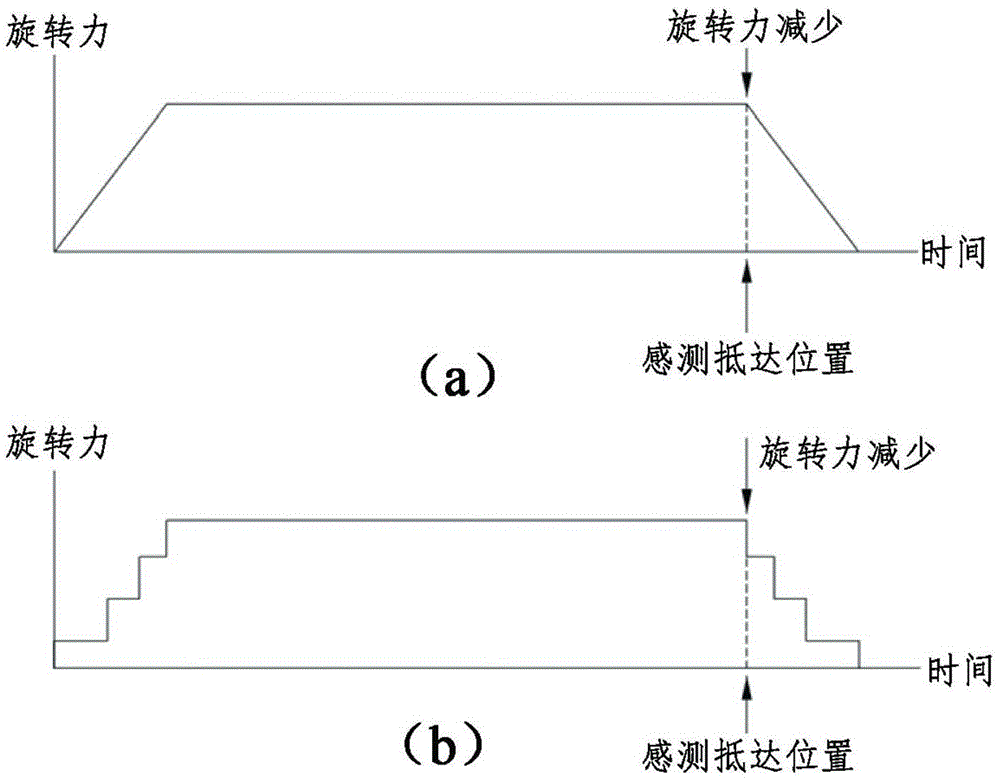

[0031] Next, preferred embodiments of the electric pressure rice cooker with the automatic pressure locking function provided by the automatic locking device and the method for controlling the automatic pressure locking function of the electric pressure rice cooker according to the present invention will be described with reference to the accompanying drawings. For reference, the terms referring to the structural elements of the present invention are named in consideration of the functions of each structure, and thus should not be construed as limiting the technical structural elements of the present invention.

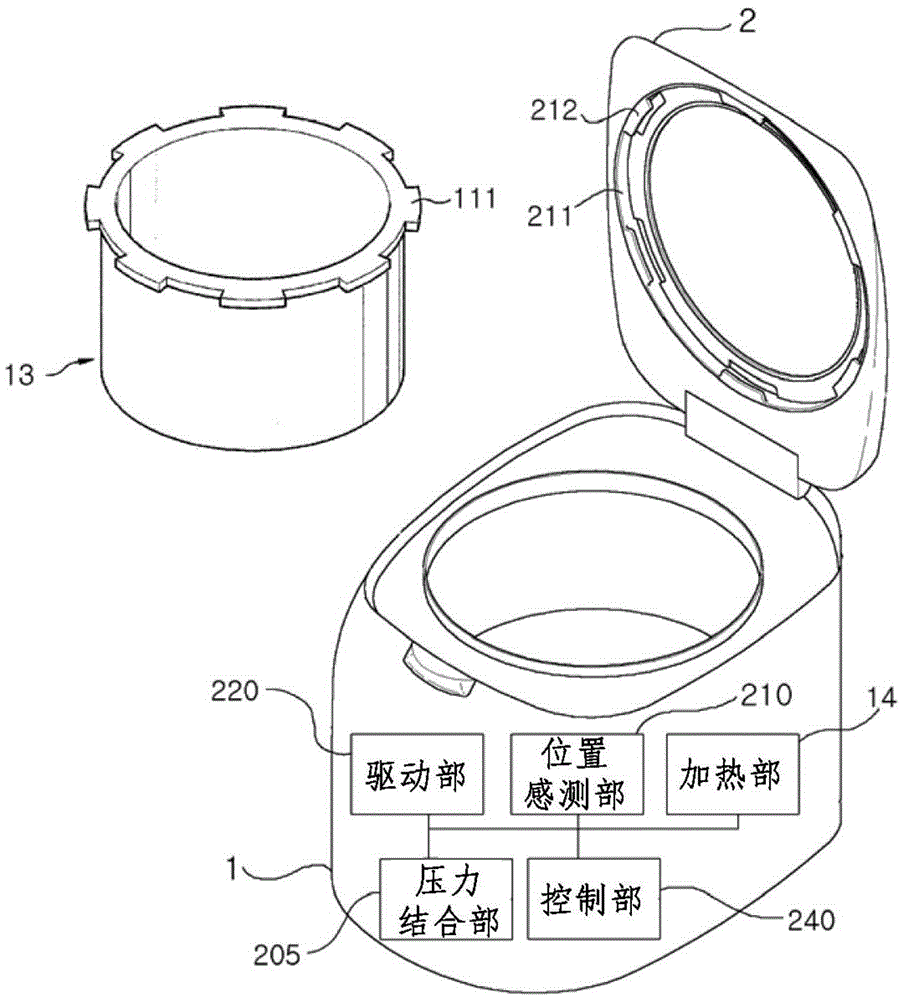

[0032] figure 1 It is a schematic block diagram showing the structure of an electric pressure rice cooker with an automatic pressure lock function according to an embodiment of the present invention. The electric pressure rice cooker includes an inner pot 13 , an outer pot 1 , a lid 2 and a control part 240 . Moreover, the electric pressure rice cooker with automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com