Preparation method of insoluble egg protein aggregate particles and application thereof

A technology of aggregate particles and egg protein, which is applied in the food field, can solve the problems of human health hazards and the single application range of protein aggregate fat substitutes, so as to increase nutritional added value, have no effect on nutritional value, and reduce lipid content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: adopting method (1) to prepare egg protein aggregate particles

[0030] The egg protein aggregate particles are prepared by directly heating under the mechanical shear condition of 600-1200rpm, and continuing to shear until the temperature is lowered to normal temperature after heating. The steps are as follows:

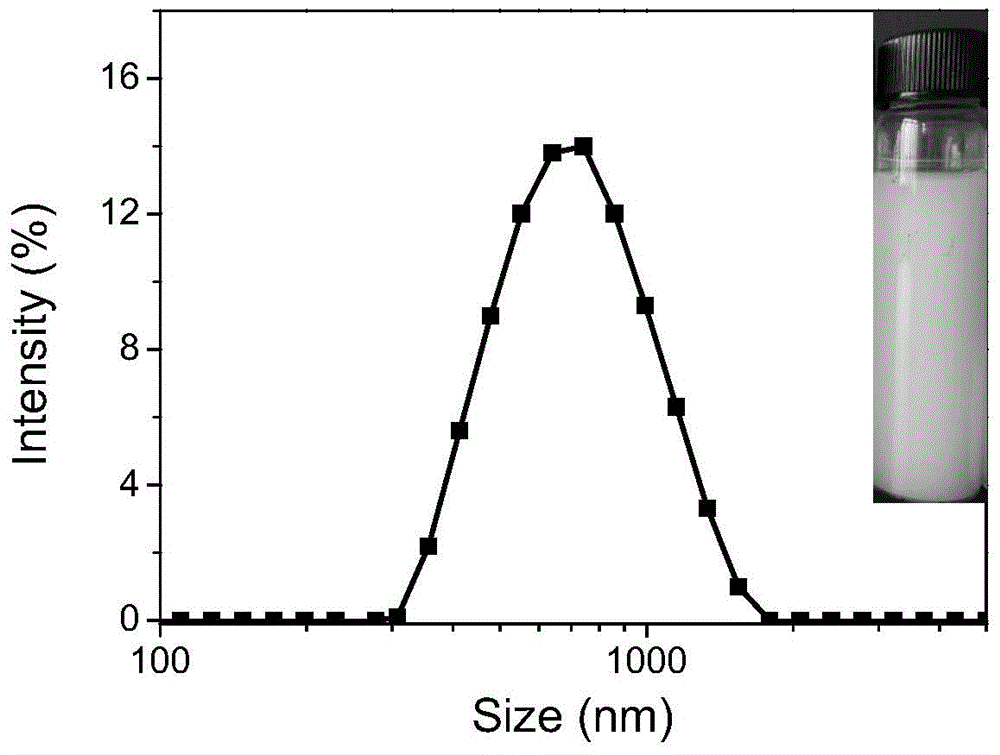

[0031]Add 1 volume of water to the egg white to dilute to a final protein mass fraction of 5%, adjust the pH to 5.0 with 2M citric acid, stir for 15 min, naturally precipitate for 1 h, and then filter to remove insoluble protein components. Dilute the pretreated egg white with water to a final protein mass fraction of 3%, adjust the pH of the diluted egg white to 3.5 with citric acid with a concentration of 2M, heat under mechanical shear, the shear speed is 800rpm, and the heating temperature is 90 ℃, the heating time is 15min. During the heating process, the egg white gradually aggregates into particles, which are stably suspended in the water ...

Embodiment 2

[0033] Embodiment 2: Using method (2) to prepare egg protein aggregate particles

[0034] Heating first to form a gel, then placing it at a low temperature for a period of time, then shearing at a high speed at 8000-15000 rpm, shearing and crushing, and then performing high-pressure homogenization to prepare egg protein aggregate particles, the steps are as follows:

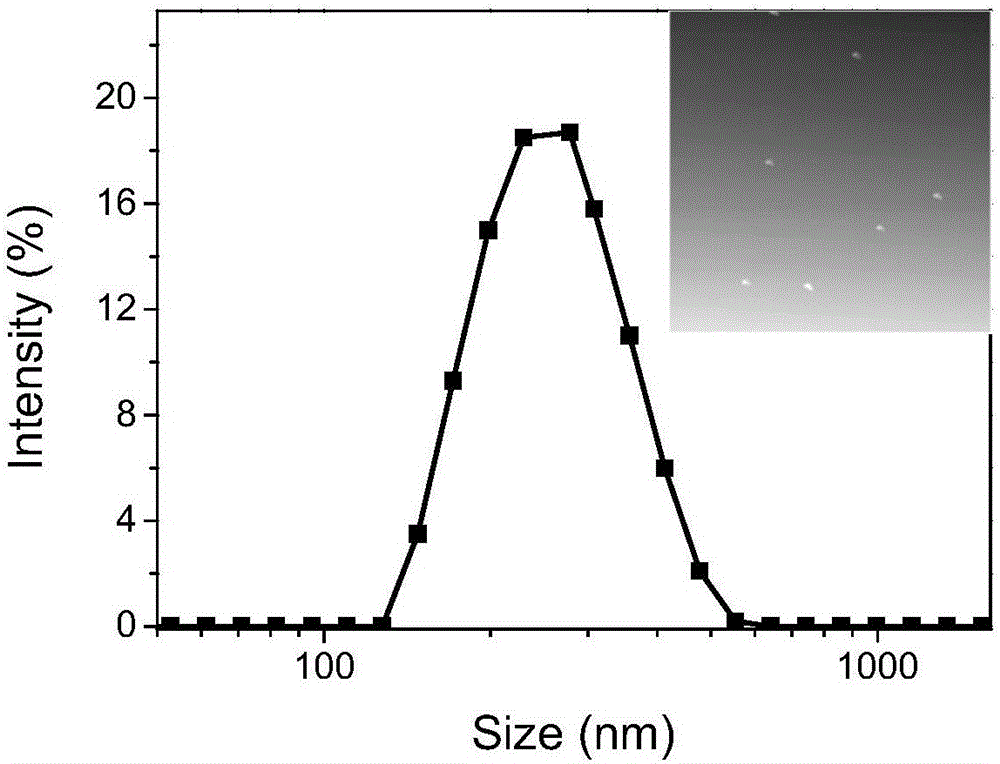

[0035] Add 1 volume of water to the egg white to dilute to a final protein mass fraction of 5%, adjust the pH to 5.0 with 2M citric acid, stir for 15 min, naturally precipitate for 1 h, and then filter to remove insoluble protein components. Adjust the pH of the pretreated egg white to 3.5 with 2M citric acid, heat it in a water bath at 90°C for 30 minutes, store the formed gel at 4°C for 24 hours, and use The gel is broken by high-speed shearing at a shear rate of 10,000 rpm. After shearing, high-pressure homogenization technology is used to further break the gel particles. The homogenization pressure is 10 MPa,...

Embodiment 3

[0037] Embodiment 3: Using method (3) to prepare egg protein aggregate particles

[0038] Heating to form a gel first, then placing it at low temperature for a period of time, and then high-speed shearing at 8000-15000rpm to prepare egg protein aggregate particles, the steps are as follows:

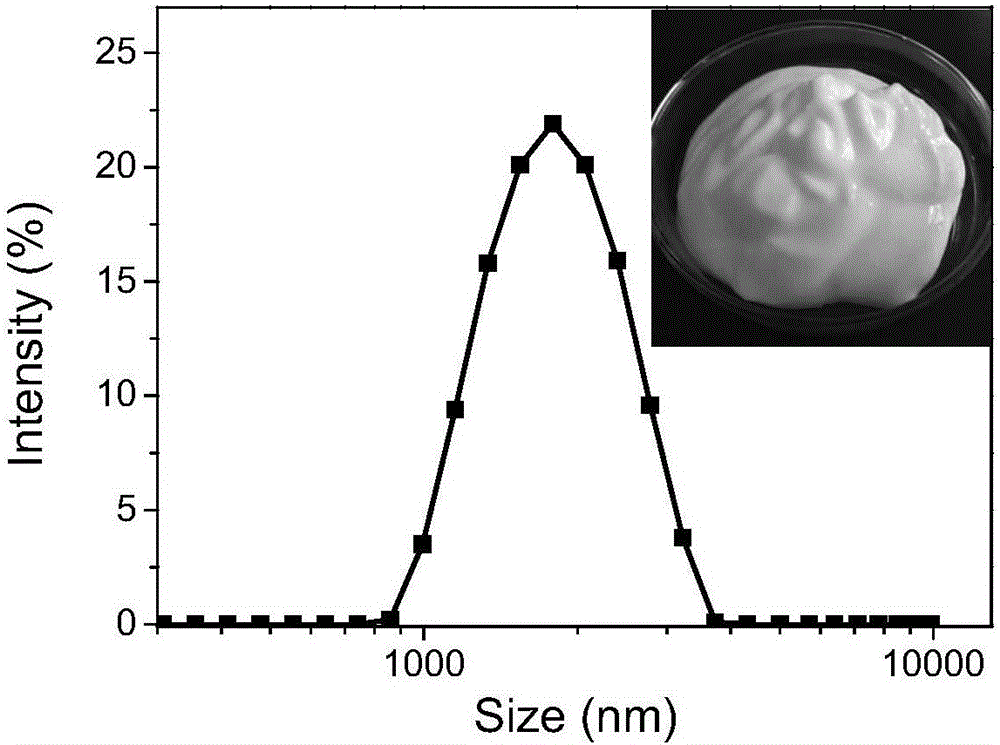

[0039] The pH of egg white was adjusted to 5.0 with 2M citric acid, stirred for 15 min, naturally precipitated for 1 h, and then filtered to remove insoluble protein components. Dilute the pretreated egg white with water to a protein mass fraction of 8%, adjust the pH of the egg white dilution to 3.8 with 2M citric acid, and heat in a water bath at a heating temperature of 90°C for 30 minutes to form After the gel was stored at 4°C for 24 hours, the gel was broken by high-speed shearing at a shear rate of 12,000 rpm, and the particle size after shearing and breaking was 1.0-3.0 μm ( image 3 ), it can be seen from the macroscopic picture that the concentration of the aggregate dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com