Thick Fiber Cleaver

A technology of cutting knife and thick optical fiber, which is applied to the coupling of optical waveguide and other directions, can solve the problems of high price and complicated structure of ultrasonic cutting knife, and achieve the effect of good cutting effect, simple structure and smooth section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

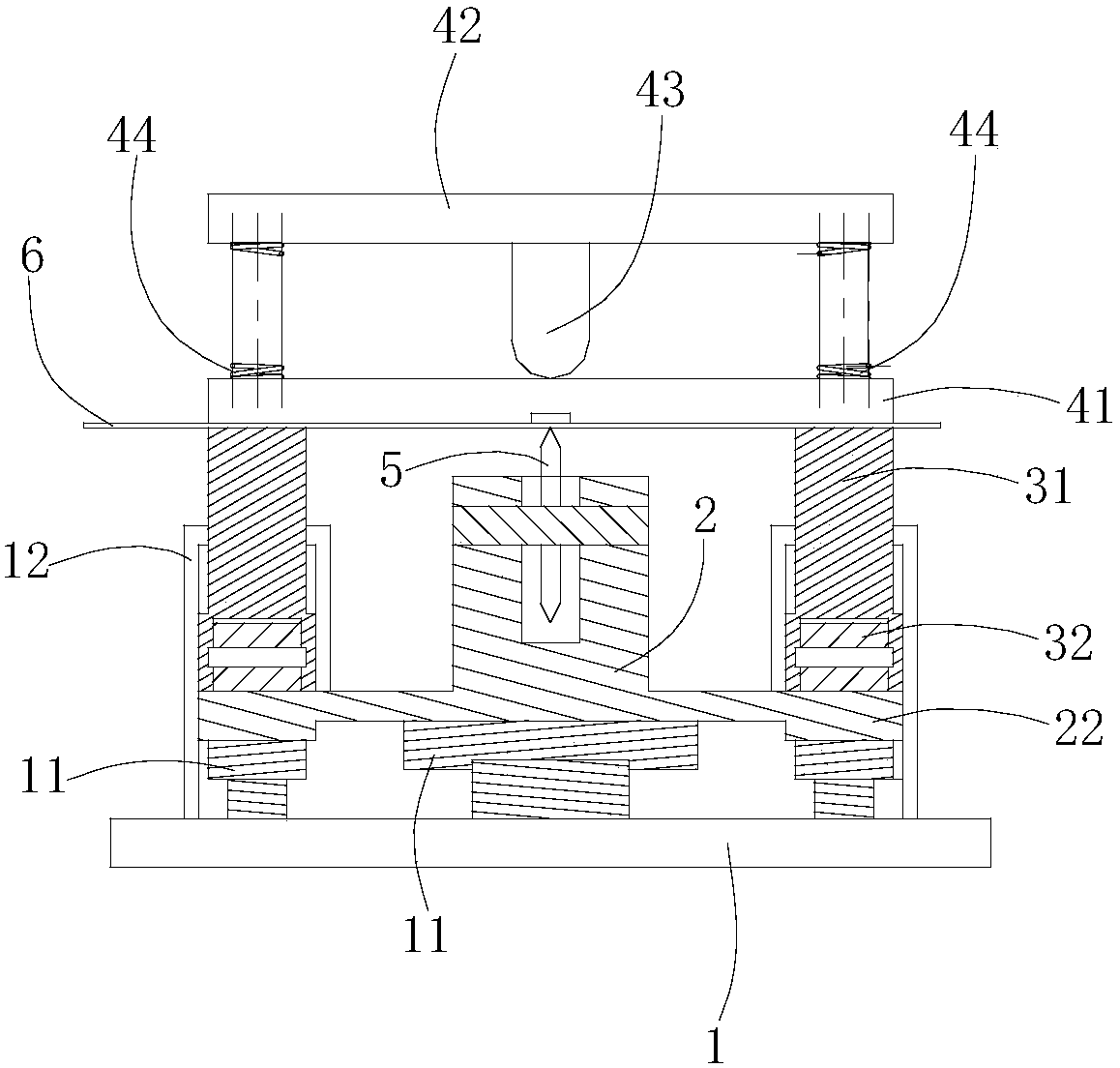

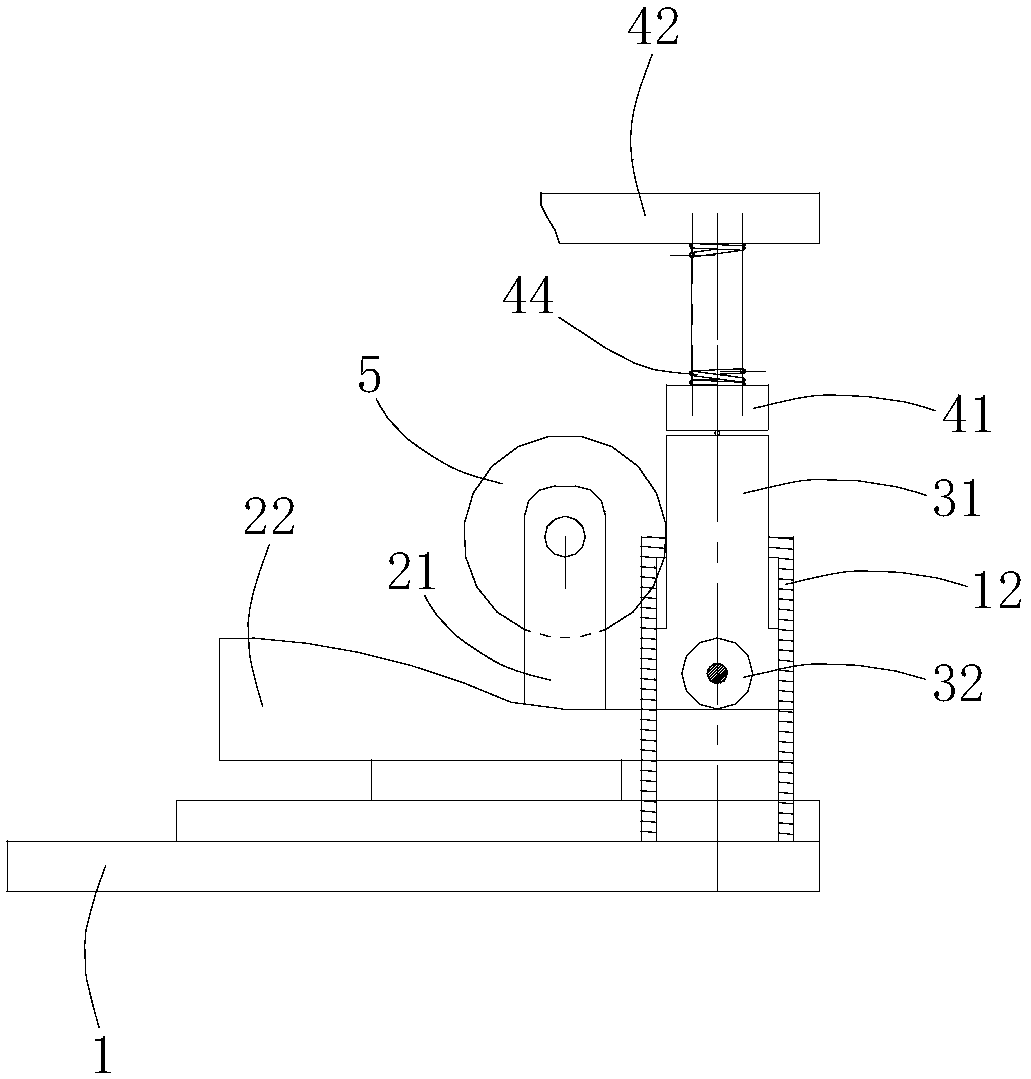

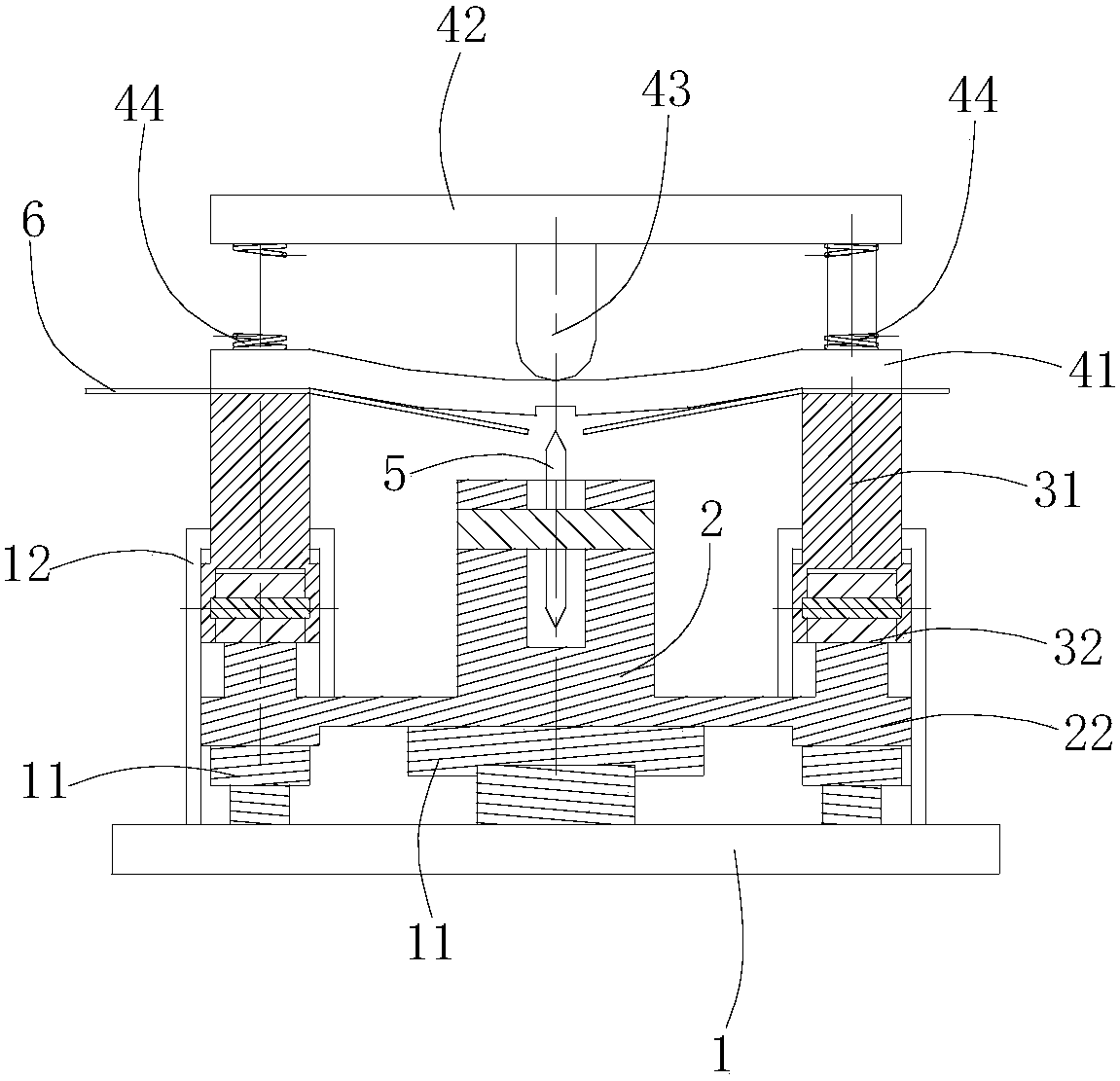

[0018] Such as Figures 1 to 5 shown

[0019] The thick optical fiber cutting knife comprises a base 1, a sliding seat 2, a cutting knife 5, an upper pressing component and a floating component.

[0020] The base 1 is provided with three guide rails 11, and the three guide rails 11 are all forward and backward and are respectively arranged on the left, middle and right parts of the upper end surface of the base 1, and the left and right sides of the base 1 are provided with two fixing frames 12 .

[0021] The sliding seat 2 is arranged on the base 1 through three guide rails 11, the middle part of the sliding seat 2 is provided with a knife rest 21, the cutting knife 5 is installed on the knife rest 21 through a pin shaft, and the left and right sides of the sliding seat 2 extend sliding blocks 22 respectively. The length (the length of the front and rear directions) of the sliding block 22 is consistent with the direction of the guide rail 11, and the upper end surface of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com