A method of vacuum evaporation coating process that effectively block blue light and infra red light on optical lenses and optical lens

An optical lens, a technology for blocking blue light, used in vacuum evaporation coating, optics, filters, etc., can solve the problem of inability to effectively block blue light and infrared light, and achieve the effect of preventing macular degeneration and cataracts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

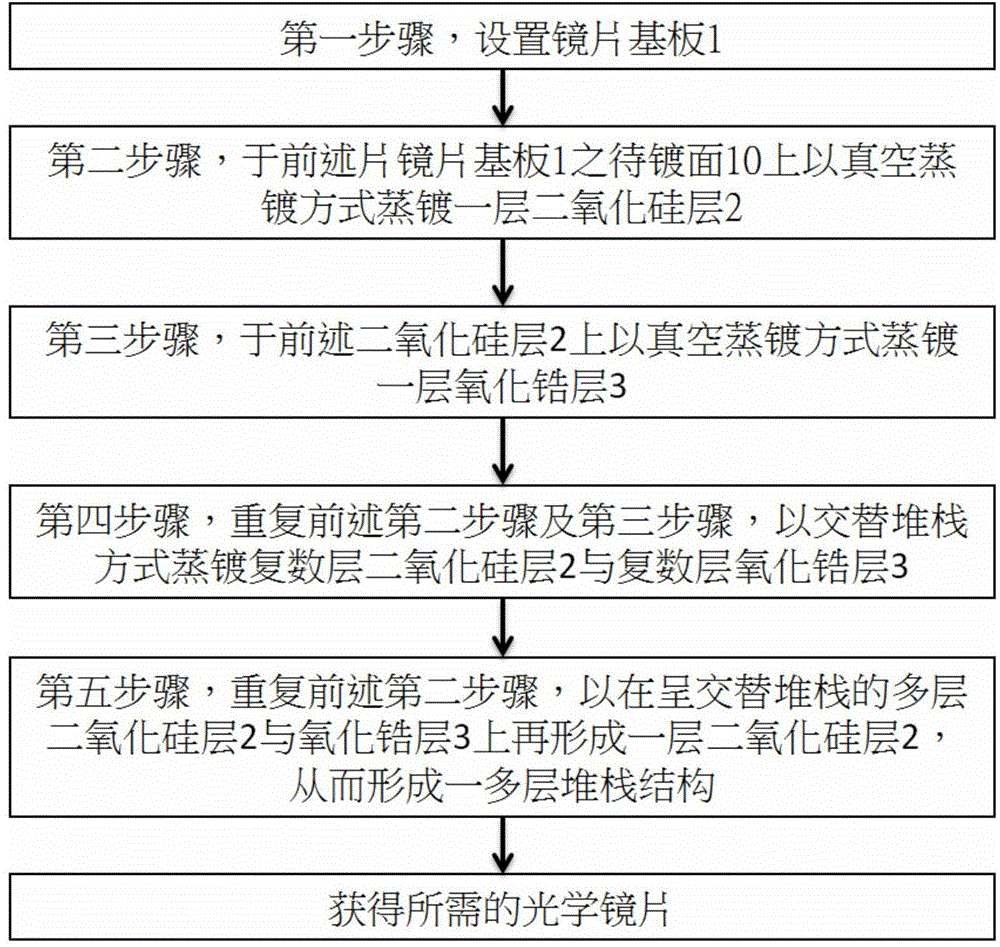

[0023] In order to further understand the present invention, the best implementation of the optical lens vacuum evaporation method that can effectively block blue light and infrared light is as follows: figure 1 Shown in the shown embodiment (one), at least include:

[0024] The first step is to set a lens substrate 1. The aforementioned lens substrate 1 is made of glass, resin, polycarbonate (polycarbonate; PC), acrylic resin (arcylic; acrylic resin), CR39 resin, NK55 resin, MR-series Optical lenses made of resin (such as MR7 resin, MR7.4 resin, MR8 resin, MR10 resin, etc.) or titanium crystal (trivex), and the aforementioned lens substrate 1 must be pre-cut into the desired shape, such as convex lens, concave lens , Myopia lenses, hyperopia lenses, astigmatism lenses, presbyopia lenses, screen lenses or other geometric shapes of lenses, depending on the needs of use. The aforementioned lens substrate 1 can be provided with a surface to be coated 10 on one side or both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com