DTS-based design method of detection system for detecting integrity of cast-in-place pile

A technology of detection system and design method, which is applied in the field of engineering, can solve the problem of no theoretical basis for the determination of optical fiber sensor layout scheme and related parameter indicators, and achieve the effect of low cost and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation, so as to facilitate a clear understanding of the present invention, but they do not constitute a limitation to the present invention.

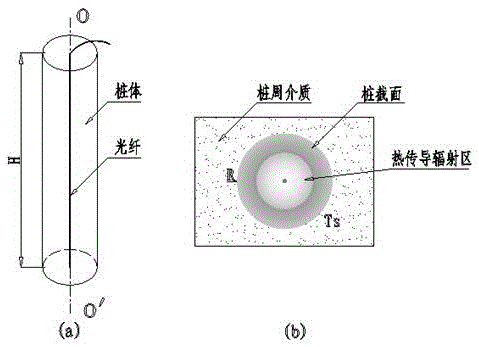

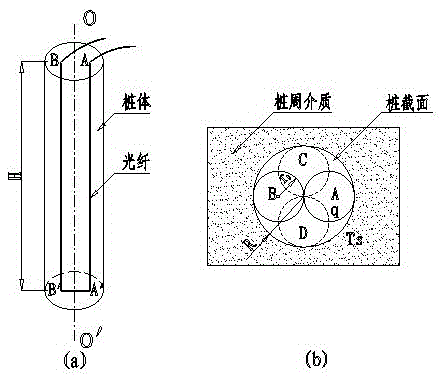

[0039] The columnar cast-in-place pile is a radially symmetrical geometry, and the sensing optical fiber is implanted in it. By heating the optical fiber, the implanted optical fiber is the internal heat source. If the optical fiber is arranged along the centerline of the pile, the material of the pile body is uniform, and the centerline of the cylinder is the symmetry line of the temperature field. Applying the heat conduction theory of the radial symmetric system to the calculation of the heat conduction of the optical fiber heat source, in order to simplify the calculation, it is assumed that the following conditions are met:

[0040] (1) Steady-state working conditions;

[0041] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com