Pressure sampling device

A sampling device and sampling bottle technology, which is applied in the field of experimental sampling, can solve problems such as difficult sampling, and achieve the effect of slowing down the pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

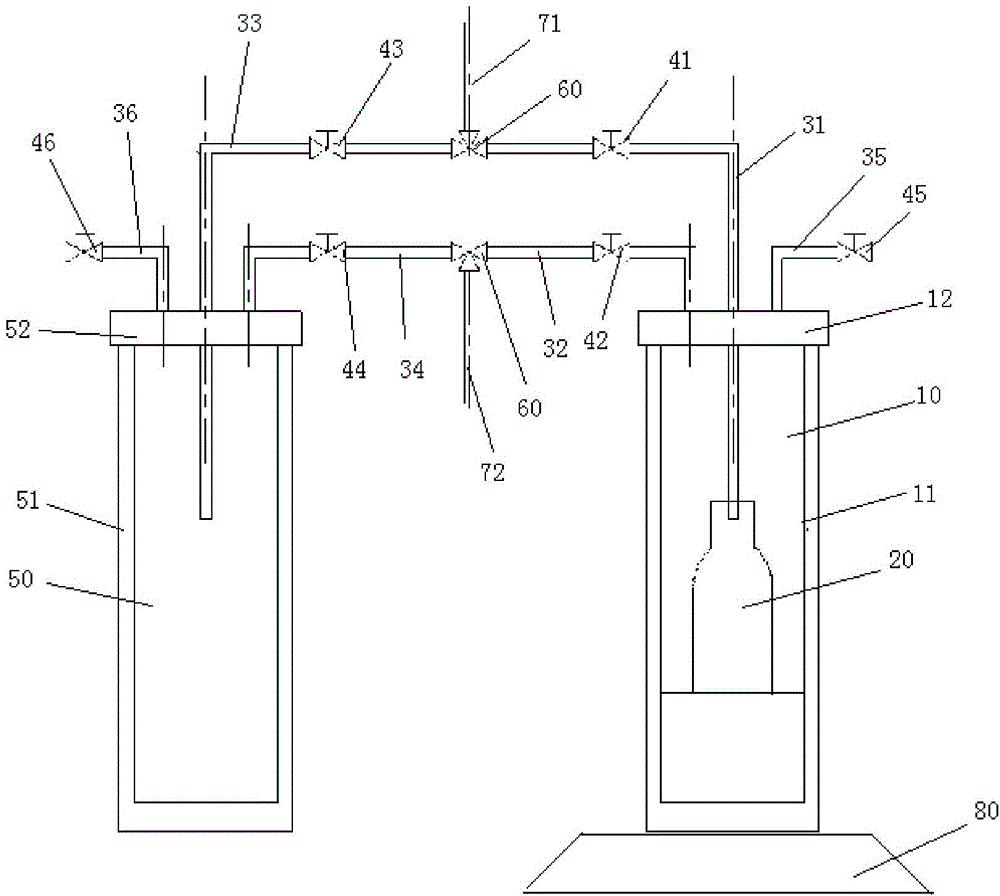

[0075] The pressure sampling device in the present embodiment comprises: a first airtight container 10; a sampling bottle 20, the sampling bottle 20 is placed in the first airtight container 10; a first pipeline 31, and one end of the first pipeline 31 passes through the first airtight container After 10, it is opposite to the bottleneck of the sampling bottle 20, and the other end of the first pipeline 31 is connected with the experimental container to be sampled; the second pipeline 32, one end of the second pipeline 32 is connected with the first airtight container 10, and the second pipeline The second end of 32 is the gas outlet; wherein, the first airtight container 10 includes a first bottle body 11 and a first sealing plug 12, and the bottle mouth of the first bottle body 11 is sealed by the first sealing plug 12.

[0076] Pass gas into the first airtight container 10 in this embodiment, keep a certain pressure in it, and make the first pipeline 31 in this embodiment be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com