Yellow phosphorus electric furnace provided with vacuum heat preservation outer layer

A vacuum insulation and outer layer technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as energy waste, achieve the effects of reducing energy consumption, obvious energy saving effects, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

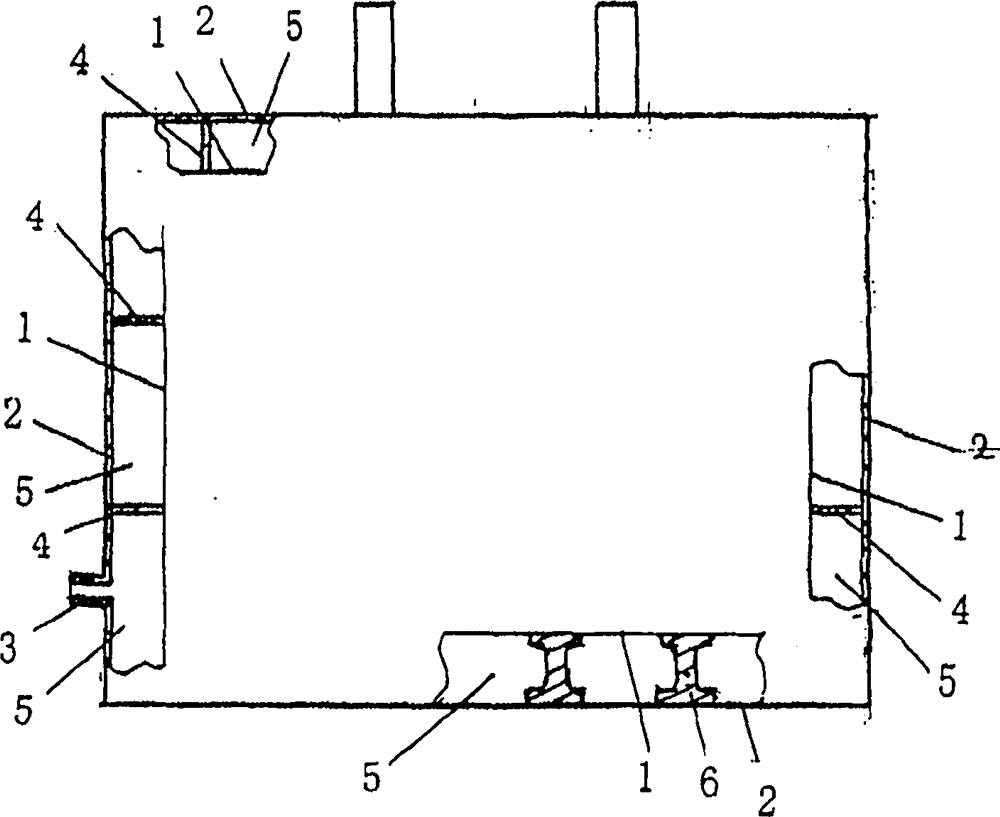

[0010] figure 1 As shown: the yellow phosphorus electric furnace is provided with a complete thermal insulation outer layer 2 on the periphery and top of the furnace body 1, and a closed vacuum thermal insulation space 5 that can be pumped is formed between the two. There is an exhaust pipe port 3 which can be connected with a vacuum pump. A plurality of support piles 4 are distributed between the furnace body 1 and the thermal insulation outer layer 2 .

[0011] During specific implementation, the thermal insulation outer layer can be processed by a steel plate with a thickness of 8 mm, and welded by an automatic welding machine protected by carbon dioxide gas. The separation distance of the heat preservation space 5 between the furnace body 1 and the heat preservation outer layer 2 is preferably 100mm, and the separation distance of the heat preservation space 5 between the furnace bottom 1 and the heat preservation outer layer 2 is preferably 200mm. The insulation space 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com