Liquid hydrogen loading system

A filling system and liquid hydrogen technology, which are used in gas/liquid distribution and storage, space navigation equipment, ship construction details, etc., can solve the problems of small filling volume, single, small pipeline diameter, etc. Redundancy and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

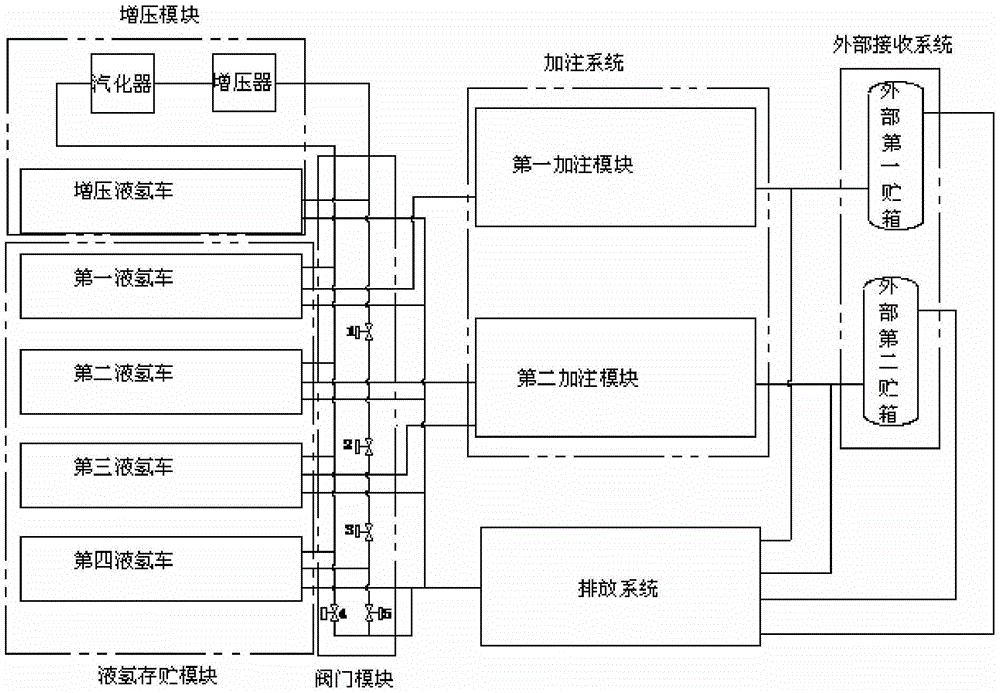

[0027] Such as figure 1 The working principle and filling process of the liquid hydrogen filling system are shown. It can be seen from the figure that it includes a pressurization module, a liquid hydrogen storage module, a valve module, a filling system, an exhaust system and an external receiving system;

[0028] Boosting module: pressurize and vaporize liquid hydrogen to generate low-temperature hydrogen, and transmit the low-temperature hydrogen to the liquid hydrogen storage module and liquid hydrogen discharge system;

[0029] Liquid hydrogen storage module: receives the hydrogen from the pressurization module, and transmits the liquid hydrogen to the filling system through the valve module through the extrusion of hydrogen, and outputs the hydrogen vaporized into the filling system during the transmission of the liquid hydrogen to the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com