A binary plug nozzle plug center body cooling structure

A technology of cooling structure and plug-type nozzle, which is applied in the direction of jet propulsion devices, machines/engines, etc., can solve the problems of difficult cooling of the central body and restrictions on the arrangement of cold air pipelines, and achieve high utilization of cold air and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

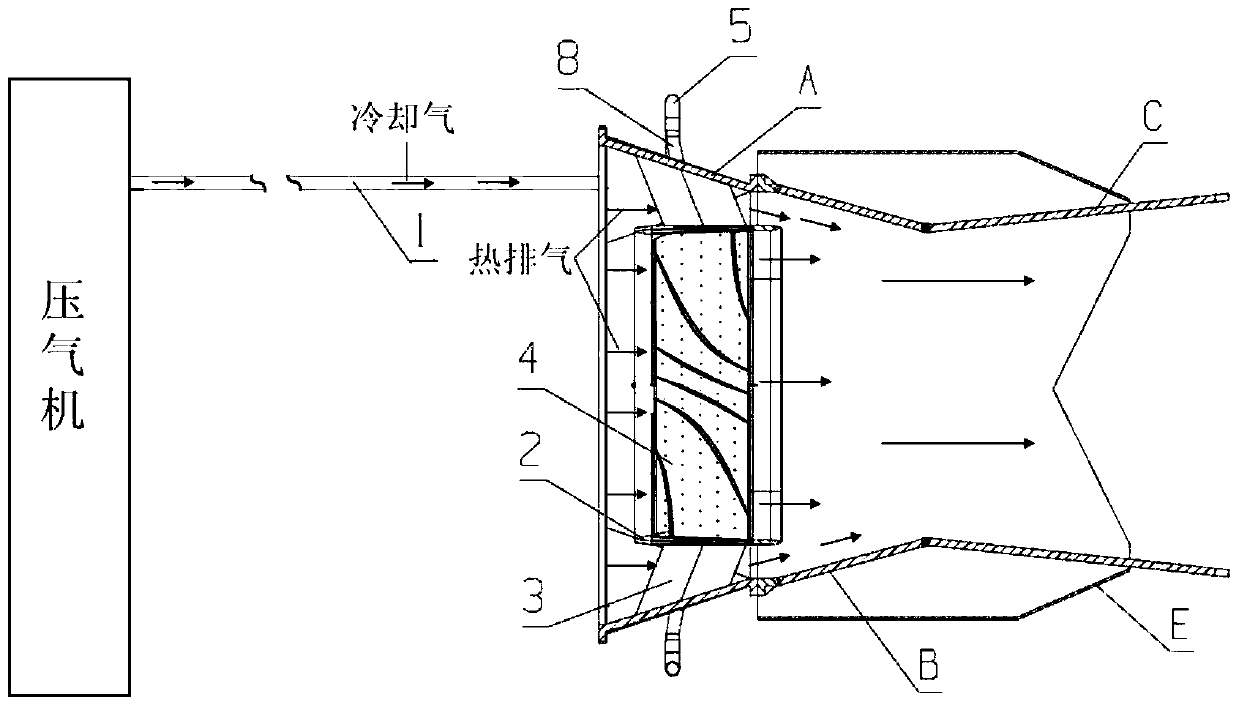

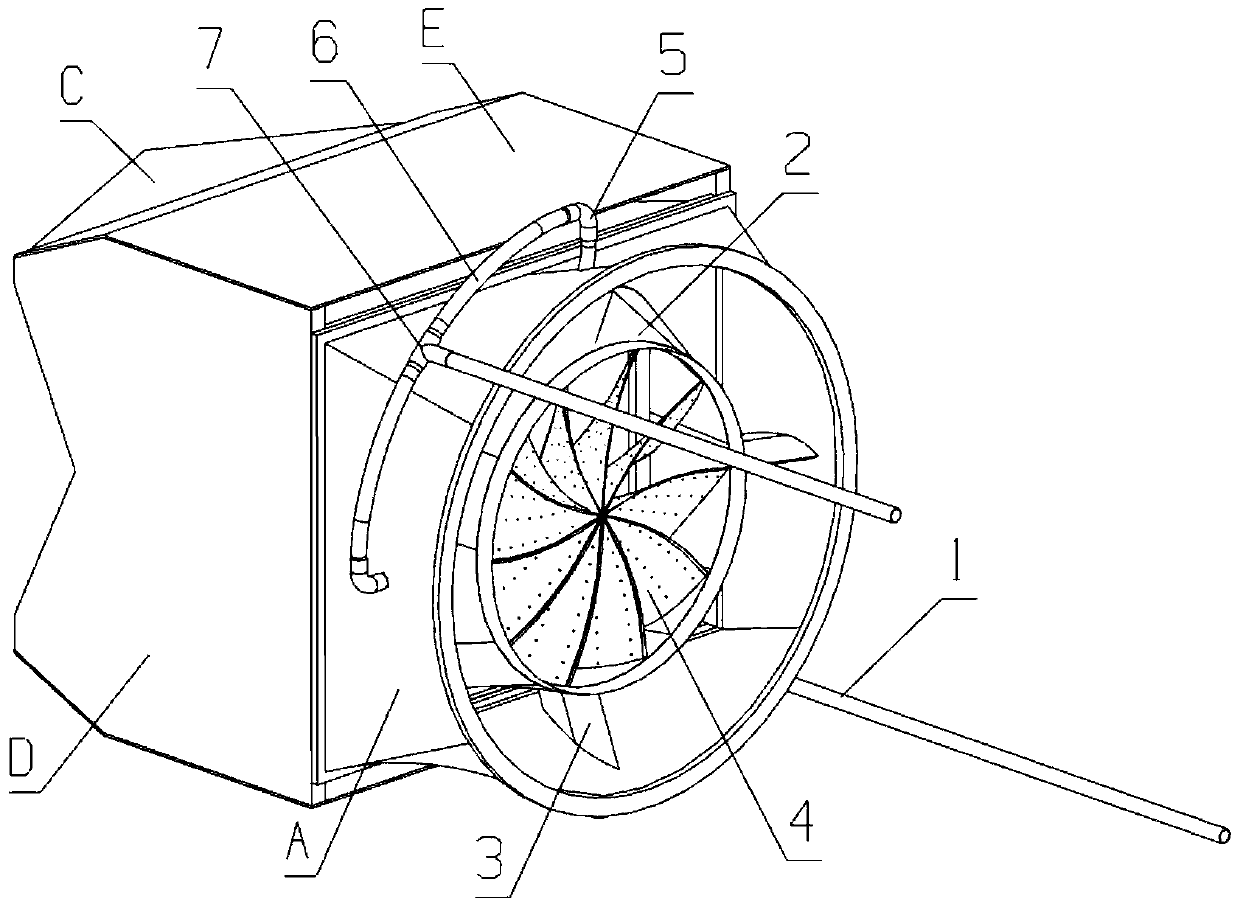

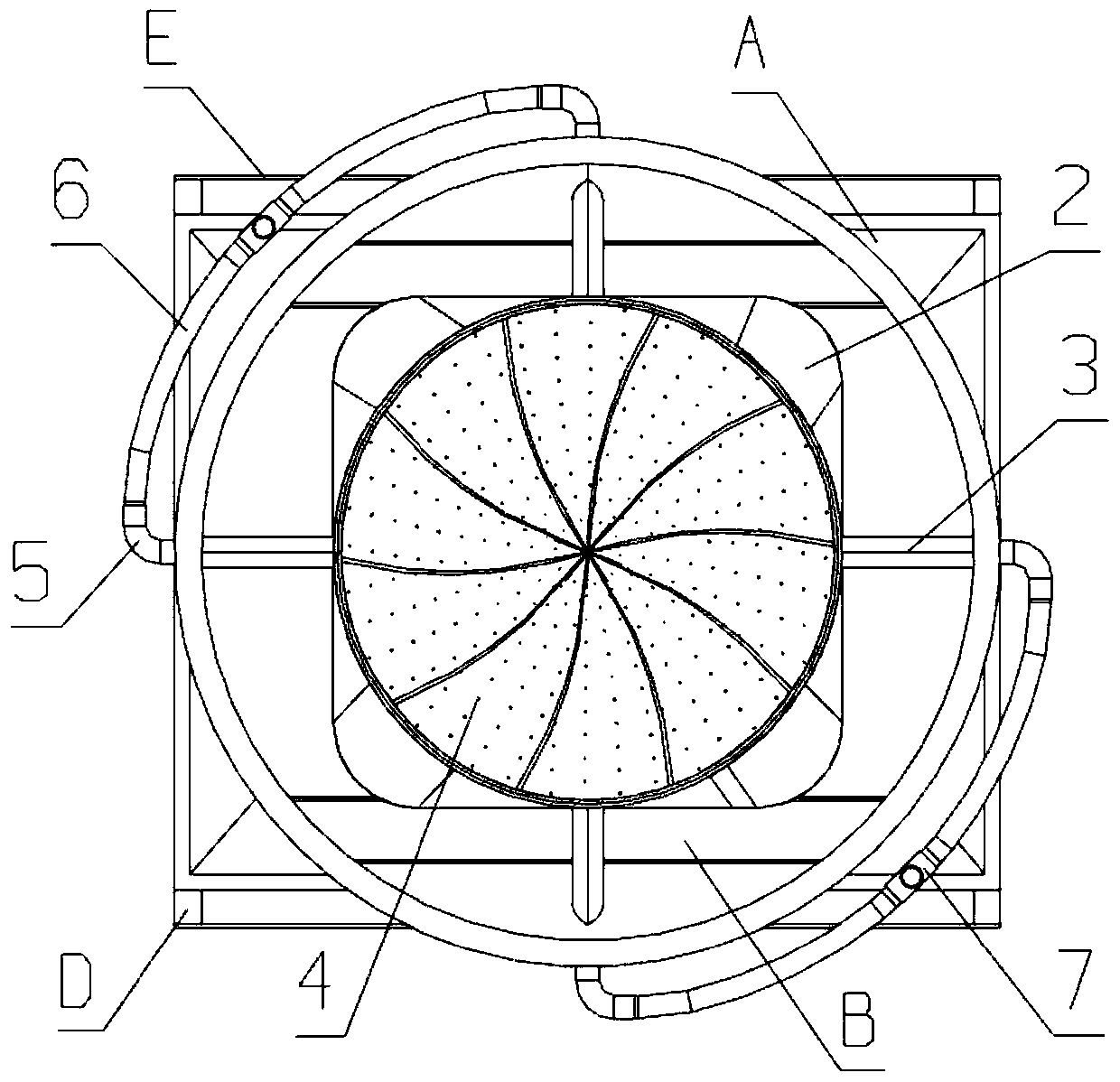

[0023] This embodiment provides a dual-plug nozzle plug-type center body cooling structure, which is characterized in that it includes a cold air pipeline, a thin-walled circular and square structure 2, a bracket 3 and a leaf-shaped structure 4 for shielding swirling flow;

[0024] Among them: the cold air pipeline includes air-inducing pipe 1, elbow 5, air-distributing pipe 6, tee joint 7 and air-guiding pipe 8; 8 enters the bracket 3, and then is introduced into the hollow structure of the thin-walled circular and square structure 2, and then the cooling air enters the cooling channel that blocks the swirling leaf-shaped structure 4, and finally flows out from the cooling air film hole against the wall of the swirling leaf-shaped structure 4. The structure forms a good cooling and protection.

[0025] The shielding swirl leaf-shaped structure 4 is arranged in the thin-walled circular square structure 2 along the circumferential direction of the cylinder wall, and the front a...

Embodiment 2

[0033] This embodiment provides a dual-plug nozzle plug-type center body cooling structure, which is characterized in that it includes a cold air pipeline, a thin-walled circular and square structure 2, a bracket 3 and a leaf-shaped structure 4 for shielding swirling flow;

[0034] Among them: the cold air pipeline includes air-inducing pipe 1, elbow 5, air distribution pipe 6, three-way joint 7 and air guide pipe 8; 8 enters the bracket 3, and then is introduced into the hollow structure of the thin-walled circular and square structure 2, and then the cooling air enters the cooling channel that blocks the swirling leaf-shaped structure 4, and finally flows out from the cooling air film hole against the wall of the swirling leaf-shaped structure 4. The structure forms a good cooling and protection.

[0035] The shielding swirl leaf-shaped structure 4 is arranged in the thin-walled circular square structure 2 along the circumferential direction of the cylinder wall, and the fro...

Embodiment 3

[0043] This embodiment provides a dual-plug nozzle plug-type central body cooling structure, which is characterized in that it includes a cold air pipeline, a thin-walled circular and square structure 2, a bracket 3 and a swirling leaf-shaped structure 4;

[0044] Among them: the cold air pipeline includes air-inducing pipe 1, elbow 5, air distribution pipe 6, three-way joint 7 and air guide pipe 8; 8 enters the bracket 3, and then is introduced into the hollow structure of the thin-walled circular and square structure 2, and then the cooling air enters the cooling channel that blocks the swirl leaf-shaped structure 4, and finally flows out from the cooling air film hole against the wall of the swirl leaf-shaped structure. The structure forms a good cooling and protection.

[0045] The shielding swirl leaf-shaped structure 4 is arranged along the circumference of the cylinder wall in the thin-walled circular square structure 2, and the front section and rear end section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com