A method and system for an integrated decarburization device for a secondary reheat unit

A technology of double reheating and decarburization, which is applied in the direction of steam engine devices, separation methods, chemical instruments and methods, etc., can solve the problems of weakening the thermal economy of the overall system, small pressure difference of small turbines, and low efficiency of small turbines, and achieves Improve thermal economy, high pressure difference, and meet the effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

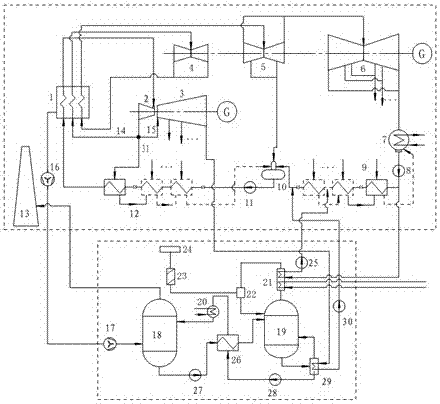

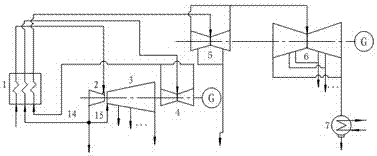

[0022] The invention introduces the decarburization device into the secondary reheating unit, and organically combines the secondary reheating technology and the decarburization technology. The boiler exhaust gas of the double reheating unit is sent to the decarburization device for decarbonization and then discharged from the chimney. The present invention is provided with a decarbonization steam turbine, and the decarbonization steam turbine uses the exhaust steam of the ultra-high pressure cylinder of the secondary reheating unit to do work, and the exhaust steam of the decarbonization steam turbine enters the reboiler in the decarbonization device for the regeneration of the carbon absorbent. The invention divides the exhaust steam of the ultra-high pressure cylinder of the double reheating unit into two parts or three parts. When the exhaust steam of the ultra-high pressure cylinder is divided into two parts: one part is sent to the boiler for primary reheating, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com