Hanging basket construction device for asymmetric arc-shaped variable cross-section thin wing plate box girder

A construction device, asymmetric technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as incompatibility, impact on traffic, construction interference, etc., to save costs, reduce interference, and reduce self-weight effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

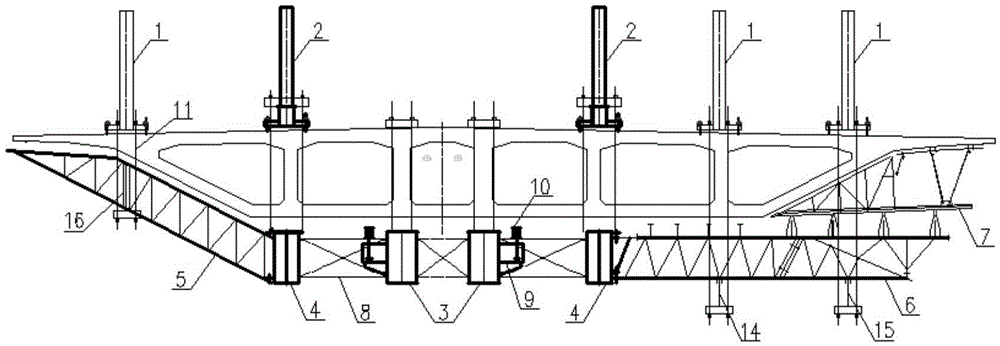

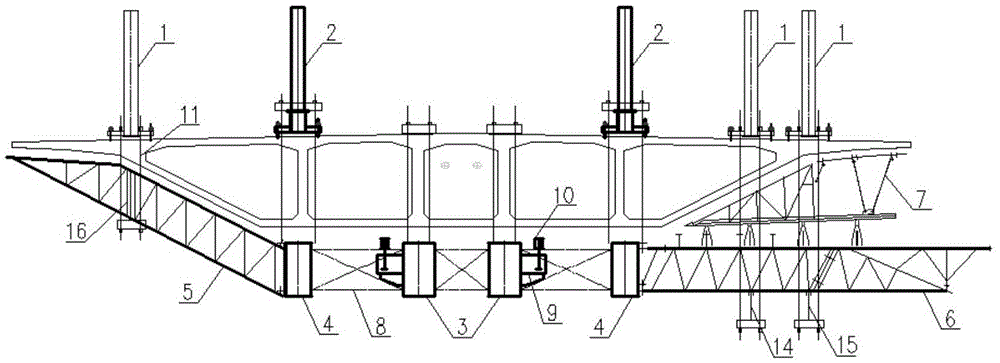

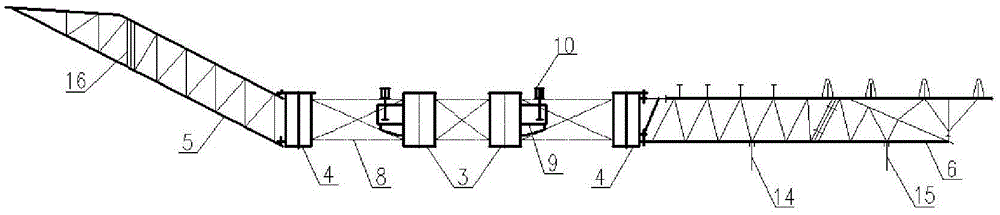

[0024] Such as figure 1 , 3 -6. A hanging basket construction device for an asymmetric arc-shaped variable-section thin-flap box girder, which includes a load-bearing platform, a cable system 13, a running system, a push-resistance system in place, an anchoring system, an operating platform, and embedded parts system, the combined structure of the main frame of the box girder and the truss constitutes the load-bearing platform of the hanging basket, the main frame of the box girder includes the main longitudinal beam 3, the two sides of the main longitudinal beam are provided with the secondary longitudinal beam 4 through the cross connection 8, and the secondary longitudinal beam on one side is connected There is a gull-wing load-bearing truss 5, which is used for the oblique web and wing plate of the box girder on the side of the standard section, and a horizontal load-bearing truss 6 connected to the secondary longitudinal beam on the other side, which is used for the const...

Embodiment 2

[0026] Such as Figure 2-6 , the structure is similar to that of Example 1. The positions of the two beam surface triangular outer main trusses on the side of the variable cross-section side box girder are set differently. 1 Only one of the two is arranged on the upper end of the adjustable height and laterally movable inclined web truss. And preferably, the outer main girders of the beam surface triangle are arranged independently of each other, and they are located at the flange plate to ensure the balance of the asymmetric arc-shaped variable-section thin-flange box girder. The triangular main truss inside the beam surface is used for anchoring the load-bearing platform of the hanging basket and guiding the walking of the hanging basket. Two main longitudinal beams are arranged at intervals, and a horizontal connection is arranged between the two main longitudinal beams. The connecting piece is Ф40 finish-rolled rebar.

[0027] The working principle of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com