Nanosilver wire polymer compound antibacterial product and preparation method thereof

A nano-silver wire, composite antibacterial technology, applied in textiles and papermaking, improved hand-feeling fibers, fiber processing and other directions, can solve the problems of easy falling off, large consumption loss, etc., and achieve the effects of good conductivity, saving consumption, and easy regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

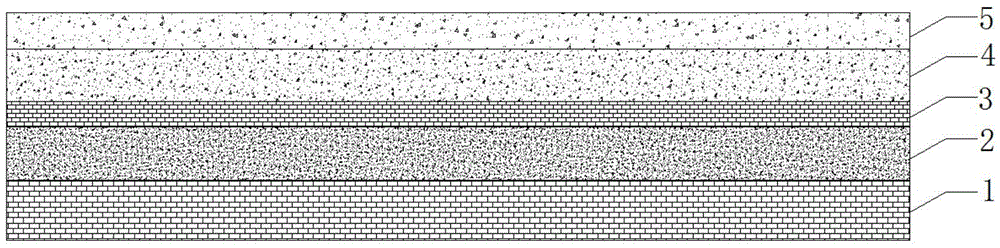

[0029] A preparation method of nano-silver wire polymer composite antibacterial product, comprising the steps of:

[0030] 1) Select the substrate and nano-silver wires with a diameter of 50-350 nm and a length of 3-80 μm, and mix the selected nano-silver wires with isopropanol and methanol to prepare a dispersion solution;

[0031] 2), put the dispersion liquid configured in step 1) into the spray gun, adjust the coefficient of the spray gun, and spray on the substrate to obtain the silver nano wire layer 1;

[0032] 3) Put the substrate prepared with nano-silver wire layer 1 into a mixed solution of silver nitrate and sodium citrate, boil for 5-10 minutes, take out, wash and dry to obtain nano-silver particle layer 2 on the surface of nano-silver wire layer;

[0033] 4) Put the substrate prepared with nano-silver wire layer and nano-silver particle layer on the coating machine, and add 1%-2% photoinitiator 2,2-dimethoxy-2- The acrylate monomer of phenyl-acetophenone is plac...

Embodiment 1

[0042] 1), select a glass sheet and a silver nanowire with a diameter of 60 nm and a length of 40 μm, and use the selected silver nanowire to mix with isopropanol and methanol to configure 5 ml of a dispersion solution, and the mass percentage of the silver nanowire in the solution is 0.15%;

[0043] 2), put the dispersion liquid configured in step 1) into the spray gun, adjust the spraying air pressure to 0.5Mpa; aim at the substrate and spray, when spraying, the distance between the gun nozzle and the glass sheet is 16cm; and the gun nozzle and the glass sheet The angle between them is 90°, that is, the nano-silver wire layer 1 is obtained; the nano-silver wire layer 1 is scanned by an electron microscope, and when it shows that there are 6 wires with a length of 1 μm, the sprayed nano-silver wire layer 1 meets the conditions;

[0044] 3) Put the base of the prepared nano-silver wire layer 1 into a mixed solution of 0.08mol / l silver nitrate and 0.003mol / l sodium citrate, boil...

Embodiment 2

[0050] 1) Select glass cylinders and silver nanowires with a diameter of 100nm and a length of 70μm, and mix the selected silver nanowires with isopropanol and methanol to prepare a dispersion solution of 10ml, and the mass percentage of silver nanowires in the solution is 0.2% ;

[0051] 2), put the dispersion liquid configured in step 1) into the spray gun, adjust the spraying air pressure to 0.6Mpa; aim at the substrate and spray, when spraying, the distance between the gun nozzle and the glass cylinder is 14cm; and the gun nozzle and the glass The angle between the pillars is 90°, that is, the silver nano wire layer 1 is obtained; the maximum transmittance of the silver nano wire layer 1 in the visible light range measured by a spectrophotometer is 90%, and the sprayed silver nano wire layer 1 meets the conditions;

[0052] 3), put the substrate of the prepared nano-silver wire layer 1 into a mixed solution of 0.1mol / l silver nitrate and 0.01mol / l sodium citrate, boil for 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com