Polyurethane surface pretreatment cleaning agent

A technology of pretreatment agent and polyurethane material, which is applied in the chemical field, can solve the problems of large amount of surfactant, low stain removal efficiency, and easy breeding of microorganisms, etc., and achieve the effects of improving application safety, saving cleaning water, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

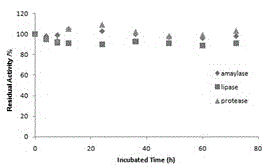

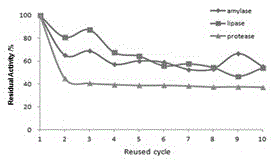

Embodiment 1

[0014] A cleaning pretreatment agent for polyurethane materials, a spray consisting of 0.01 gram of protease and auxiliary materials with decontamination active ingredients, the sum of the mass of each raw material is 100 grams, and the auxiliary materials are composed of 0.7 grams of potassium dihydrogen phosphate, hydrogen 0.1 gram of sodium oxide, 0.01 gram of anhydrous calcium chloride, and the remainder is deionized sterile water.

Embodiment 2

[0016] A cleaning pretreatment agent for polyurethane materials, a spray consisting of 0.05 grams of lipase and auxiliary materials with decontamination active ingredients, the mass sum of each raw material is 100 grams, and the auxiliary materials are composed of 0.7 grams of potassium dihydrogen phosphate, 0.1 g of sodium hydroxide, 0.01 g of anhydrous calcium chloride, and the remainder is deionized sterile water.

Embodiment 3

[0018] A kind of polyurethane material cleaning pretreatment agent, is the spray that is made up of amylase of 1 gram and auxiliary material by decontamination active component, and the mass summation of its each raw material is 100 grams, and described auxiliary material is composed of potassium dihydrogen phosphate 0.7 gram, 0.1 g of sodium hydroxide, 0.01 g of anhydrous calcium chloride, and the remainder is deionized sterile water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com