Method for preparing tulathromycin

A teramycin and reactor technology, which is applied in the field of preparing teramycin, can solve the problems of large amount of n-propylamine, low content of crude product, bad properties, etc., and achieves the effects of improved selectivity and good quality of crude product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

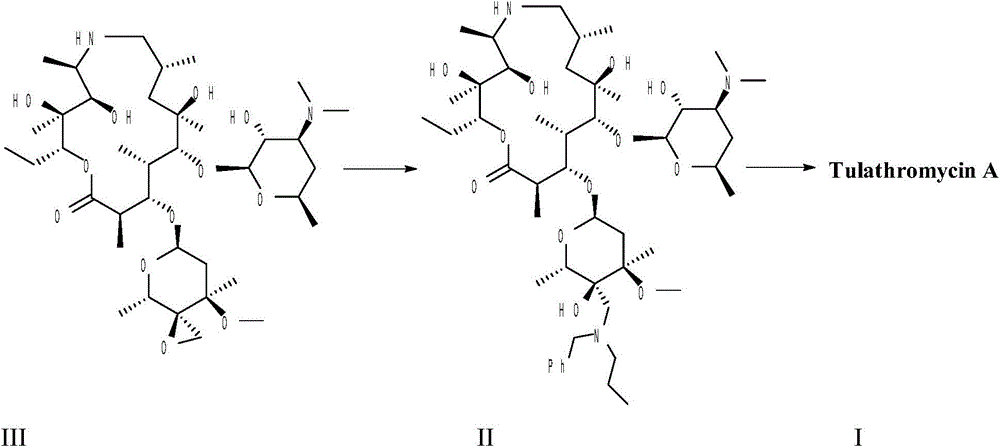

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of method for preparing telamycin of this example, its steps are:

[0023] a. Add epoxy intermediate (III) (747g, 1.0mol), isopropanol (5950g), N-benzylpropylamine (178.8g, 1.2mol) to the reactor and stir well, then heat to 50-60 ℃ stirring reaction for 36 hours;

[0024] b. After completion of the reaction, concentrate and remove most of the solvent, then add acetone (7450g), stir and transfer to the pressure reactor;

[0025] c. Add 10% palladium-carbon catalyst (74.7g) in the pressure reactor, feed hydrogen, keep the reaction solution at 20-30°C, stir and react under 50psi pressure for 24 hours, filter and recover the catalyst after the reaction, and concentrate to remove most of it Solvent, then water (7470g) was added, the precipitated solid was collected by filtration, and the crude product of telamycin was obtained after vacuum drying. After recrystallization, 621.7g of fine product was obtained, with a yield of about 77.1%.

[0026] The co...

Embodiment 2

[0027] Embodiment 2: a kind of method for preparing telamycin of this example, its steps are:

[0028] a. Add epoxy intermediate (III) (747g, 1.0mol), isopropanol (3750g), N-benzylpropylamine (149g, 1.0mol) into the reactor and stir well, then heat to 50-60°C Stir the reaction for 24 hours;

[0029] b. After completion of the reaction, concentrate and remove most of the solvent, then add acetone (6000g), stir and transfer to the pressure reactor;

[0030] c. Add 10% palladium-carbon catalyst (74.7g) in the pressure reactor, feed hydrogen, keep the reaction solution at 20-30°C, stir and react under 50psi pressure for 20 hours, filter and recover the catalyst after the reaction, and concentrate to remove most of it Solvent, and then add water (7470g), filter and collect the precipitated solid, obtain the crude product of telamycin after vacuum drying, obtain the fine product 435.6g after recrystallization, the yield is about 54.0%.

[0031] The content of the obtained fine tel...

Embodiment 3

[0032] Embodiment 3: a kind of method for preparing telamycin of this example, its steps are:

[0033] a. Add epoxy intermediate (III) (747g, 1.0mol), isopropanol (4800g), N-benzylpropylamine (163.9g, 1.1mol) to the reactor and stir well, then heat to 50-60 ℃ stirring reaction for 30 hours;

[0034] b. After completion of the reaction, concentrate and remove most of the solvent, then add acetone (6700g), stir and transfer to the pressure reactor;

[0035] c. Add 10% palladium-carbon catalyst (74.7g) in the pressure reactor, feed hydrogen, keep the reaction solution at 20-30°C, stir and react under 50psi pressure for 22 hours, filter and recover the catalyst after the reaction, and concentrate to remove most Solvent, then add water (7470g), filter and collect the precipitated solid, obtain the crude product of telamycin after vacuum drying, and obtain 503.8g of fine product after recrystallization, the yield is about 62.5%.

[0036] The content of the obtained fine telamycin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com