Proportional Zoned Stability Control Torque Limiting System

A stability control and sub-area technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation device, servo motor components, etc., can solve the loss of crane lifting capacity, high performance requirements of the controller, and increase the system failure rate and other issues, to achieve the effects of high security, improved utilization efficiency, and good stability control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

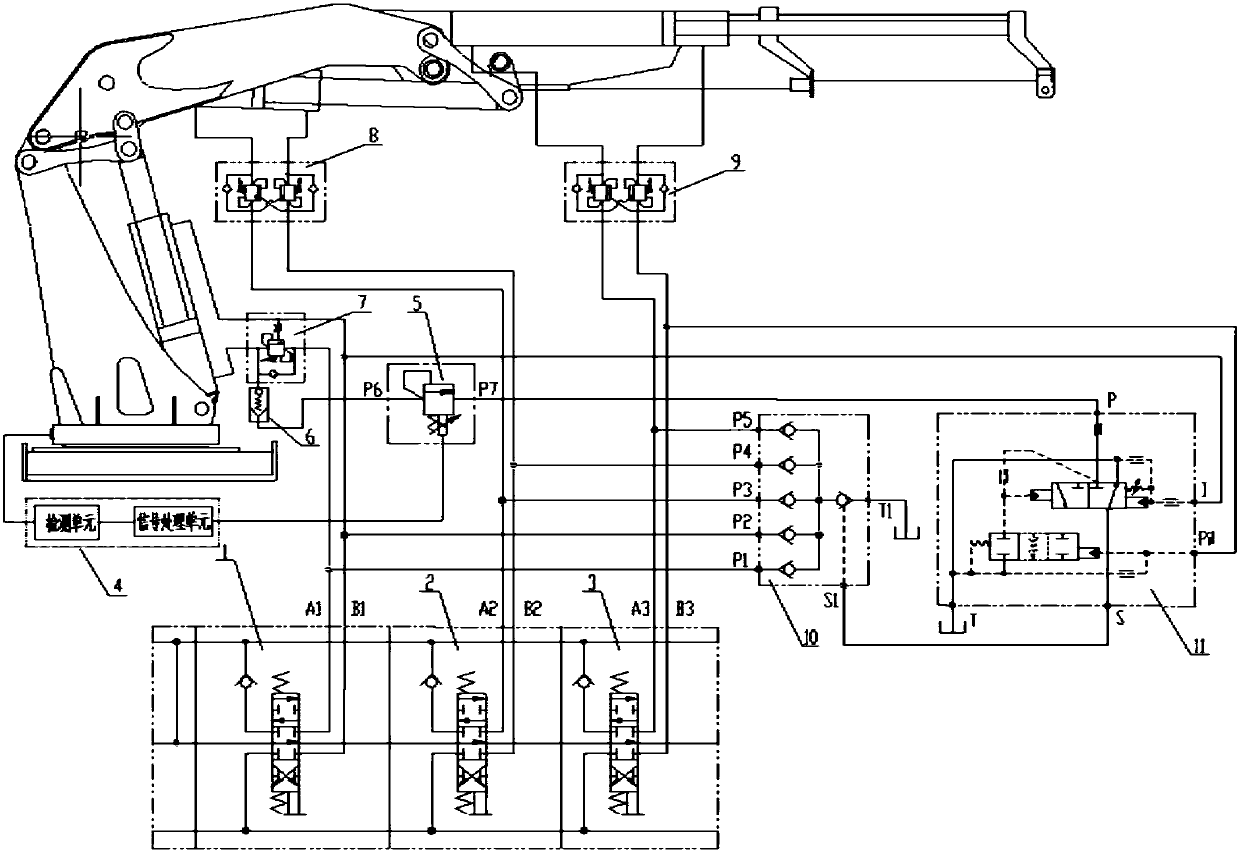

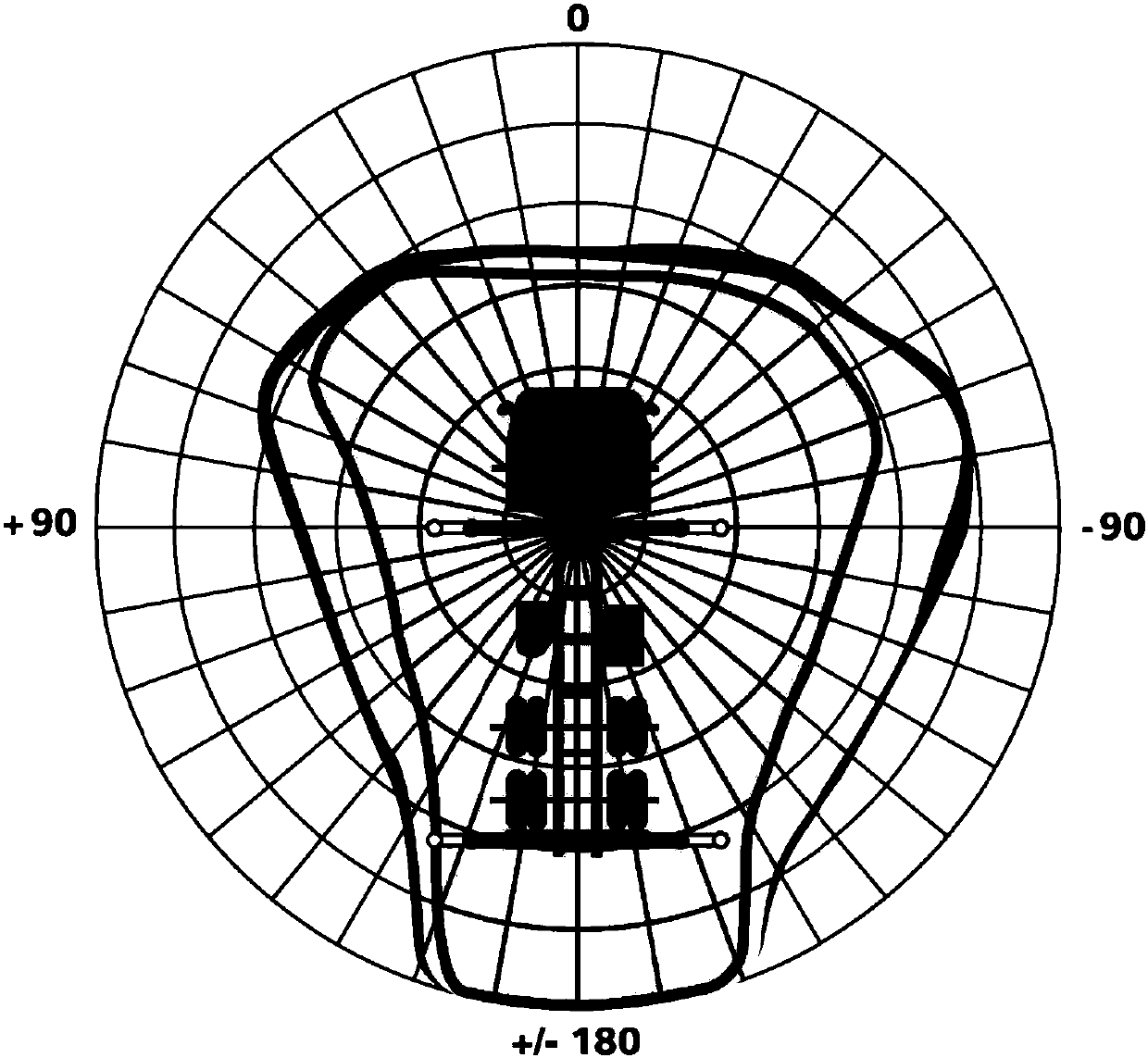

[0037] Embodiment: Taking the knuckle-arm truck-mounted crane equipped with a proportional sub-area stability control moment limiting system as an embodiment,

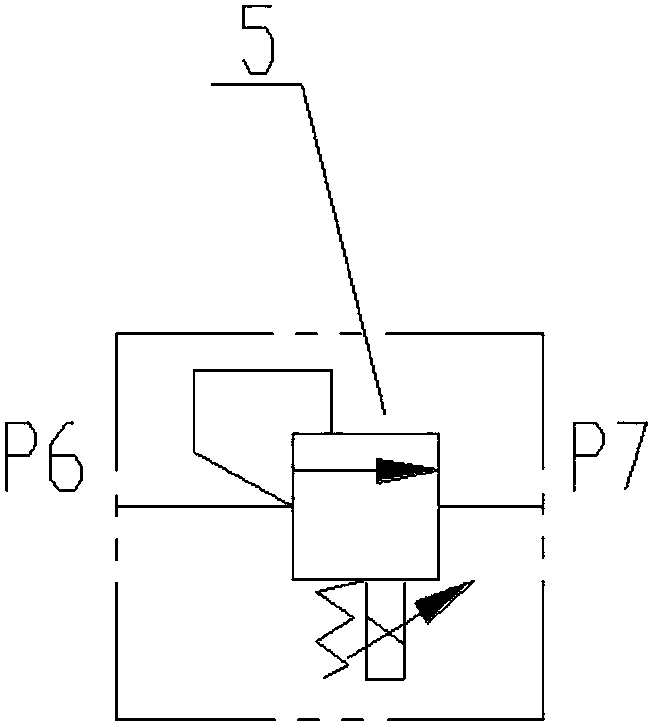

[0038] Input the allowable maximum working torque values corresponding to different working areas in the slewing area of the crane into the signal processing unit of the area detection unit 4, and the signal processing unit calculates the maximum working torque at the maximum working torque according to the actual operating conditions and geometric dimensions of the crane. The pressure value generated by the rodless chamber of the first luffing cylinder is calculated according to the pressure value of the rodless chamber of the first luffing cylinder to calculate the size of the electrical signal value to be output, and then the area detection unit can be determined for each actual working area of the crane 4 The electrical signal value that should be output. When the detection unit of the area detection unit 4 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com